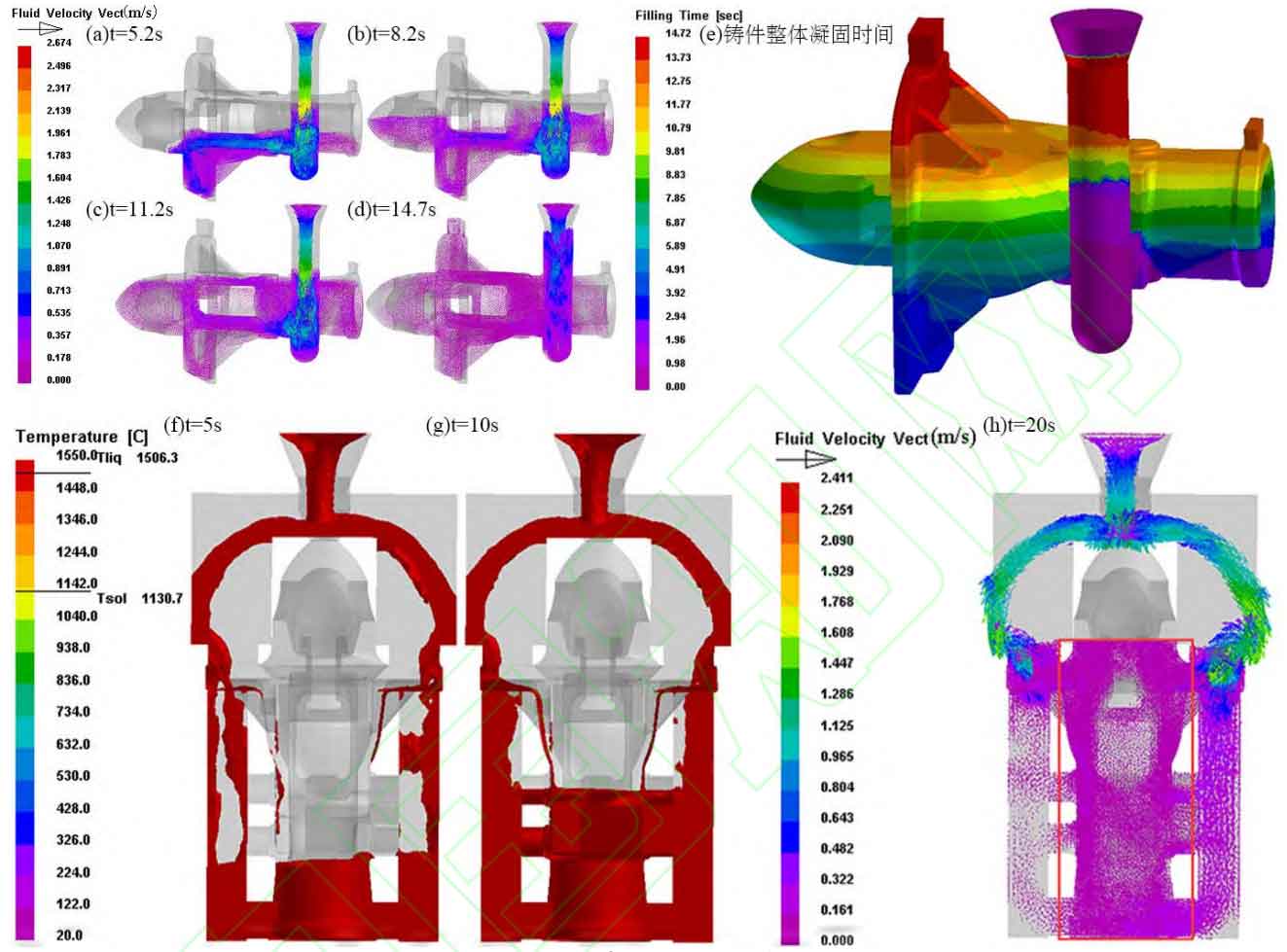

During the mold filling process of investment castings in gating system scheme a, the metal liquid flows from the sprue into the side gate and then into the mold cavity, as shown in figures (a) ~ (e).

It can be seen from figure (a) that at the beginning of mold filling, the pouring speed at the lower part of the investment casting is fast, reaching 0.71m/s, and slight air entrainment occurs. With the continuation of the filling process, the entrainment disappears, the internal filling of the whole investment casting tends to be stable, the speed drop remains below 0.36m/s, and the cavity can be completely filled in about 15s. It can be seen that the liquid fluidity of the gating system scheme is good and the energy loss in the whole pouring process is small.

The investment casting of gating system scheme B is well filled, as shown in figure (f) ~ (H). Figures (f) and (g) show that the metal liquid level in the mold cavity of investment casting rises steadily, and the metal liquid can completely fill the mold cavity; Figure (H) shows the particle tracking diagram of metal liquid flow in the mold cavity when the mold filling is 70%. It can be seen that the liquid flow in the mold cavity of investment casting is stable, there is no entrainment, the fastest speed is only 0.48m/s, the speed is low and uniform, which is conducive to exhaust and scum.

According to the filling results of the two schemes, the overall filling process speed of scheme B is more reasonable, the speed is 0.23m/s less than that of scheme a, the process is more stable, there is no phenomenon of air entrainment and metal liquid impacting the cavity, which is conducive to forming investment castings with good surface quality.