The detection and analysis show that the main reason for the crack of the valve body is that it has micro cracks. At the same time, it expands and forms cracks under the action of high temperature, high pressure and medium.

The casting material of valve body is ZG15Cr1Mo1V. There is no spheroidization evaluation standard for this material in China. It is rated according to the spheroidization evaluation standard of 12Cr1MoV Steel for thermal power plant [1] in DL / T 773-2016. After testing, the structure of the valve body is ferrite plus a small amount of pearlite plus carbide. The spheroidization level of the valve body of No. 1 furnace and No. 2 furnace reaches level 4 (complete spheroidization).

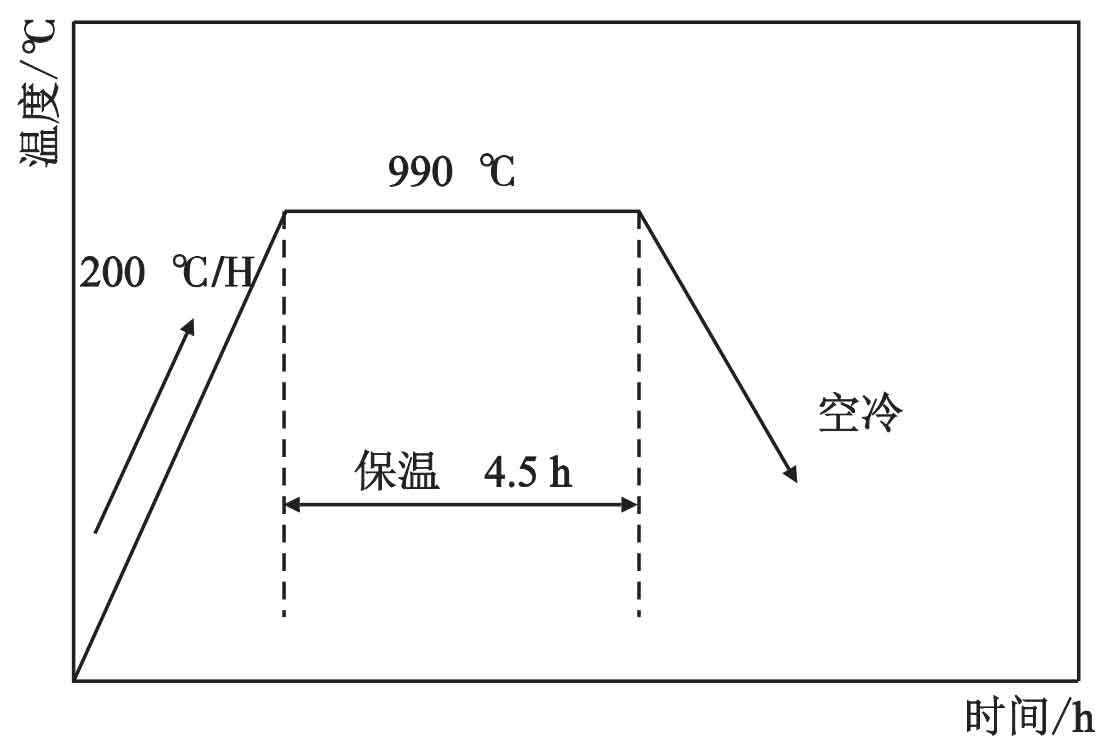

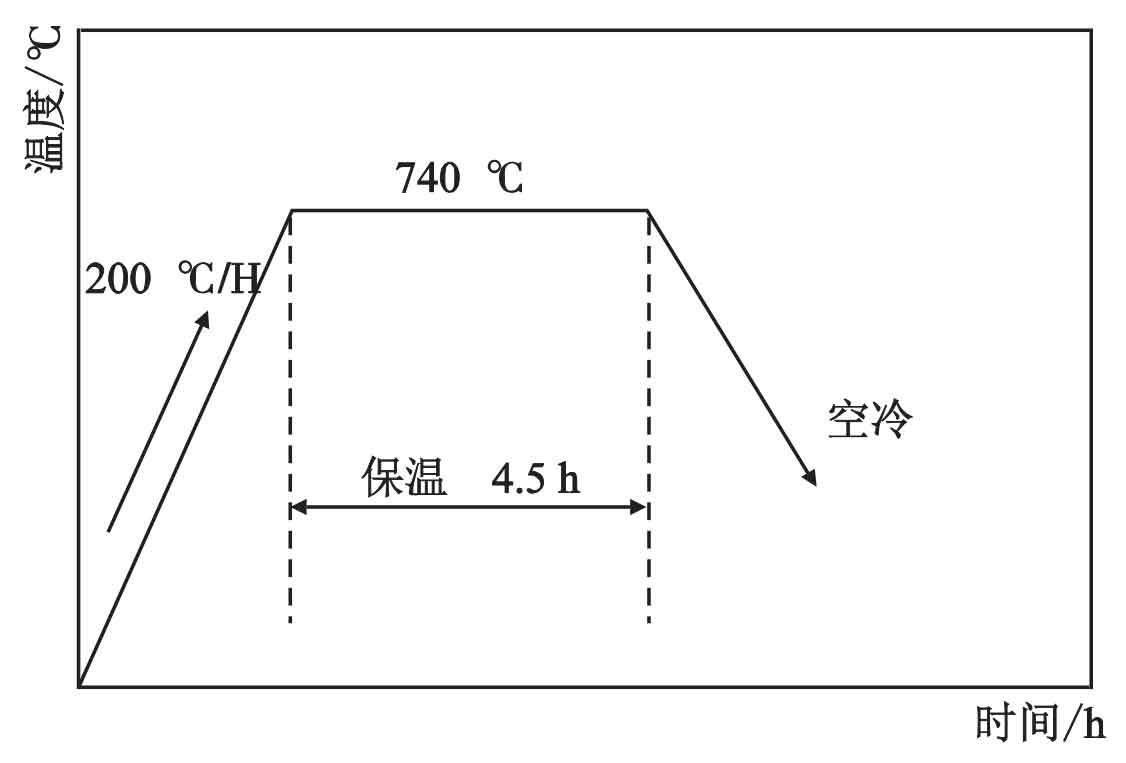

The main reason why the metallographic spheroidization reaches grade 4 (complete spheroidization) is the unreasonable heat treatment system after casting of ZG15Cr1Mo1V casting. The heat treatment of ZG15Cr1Mo1V castings is secondary normalizing + secondary tempering. The normalizing temperature is generally controlled at 990 ± 10 ℃, and the holding time is generally controlled at 25 mm / h according to the wall thickness of the valve body, as shown in Figure 1. The tempering temperature is generally controlled at 740 ± 10 ℃, and the holding time is also controlled at 25 mm / h, as shown in Figure 2.

It should be pointed out that the cooling rate of air cooling after normalizing must be controlled. Generally, the furnace should not be too full, and there should be sufficient space between parts. In addition, in order to ensure the cooling speed, it is particularly important to use an electric fan for blowing. If the cooling is not sufficient, the metallographic spheroidization can not reach grade 1. Generally, the metallographic structure determines the performance. The metallographic structure can not meet the requirements, and the material mechanical properties of parts can not meet the requirements.

| Spheroidization level | Tensile strength RM / MPa | Yield strength rel / MPa | Brinell hardness / HBW |

| Level 1 | 576 | 409 | 175 |

| Level 2 | 553 | 360 | 173 |

| Level 3 | 495 | 335 | 152 |

| Level 4 | 476 | 305 | 134 |

| Level 5 | 406 | 225 | 118 |

According to DL / T 438-2016 Technical Supervision Regulation for metal in thermal power plant and its provisions on the hardness value of common metal materials in power plant, the hardness value of ZG15Cr1Mo1V material is 140 ~ 220 HBW. The hardness value of the tested valve casting is 114 ~ 125 HBW, which is below the lower limit specified in the standard, which is seriously unqualified.

| Spheroidization level | Tensile strength RM / MPa | Yield strength rel / MPa | Brinell hardness / HBW |

| Level 1 | 588 | 449 | 178 |

| Level 2 | 584 | 445 | 176 |

| Level 3 | 478 | 332 | 148 |

| Level 4 | 442 | 298 | 136 |

| Level 5 | 412 | 267 | 125 |

The main reason for the serious low hardness value is also the non-standard implementation of the heat treatment system, mainly due to the unreasonable cooling rate after normalizing.

Appendix D of DL / T 773-2016 standard lists the microstructure and mechanical properties corresponding to each spheroidization level of 12Cr1MoV steel, as shown in Table 1 and table 2.

According to the corresponding relationship between microstructure spheroidization level and mechanical properties in Table 1 and table 2, the microstructure of the material can be judged simply by testing the Brinell hardness of the material. Fig. 3 is the metallographic microstructure of the valve body casting remade according to the heat treatment system. Its microstructure is ferrite plus pearlite plus bainite, and there is no obvious spheroidization (spheroidization level 1).

It should be pointed out here that in order to reach grade 1 of metallographic spheroidization, in addition to strictly implementing the heat treatment system, the casting method also has a certain impact. For example, the metallurgical structure of electric arc furnace smelting casting is easier to ensure than that of medium frequency furnace casting. For metallographic inspection of castings, if portable metallographic detector is used, it shall be less than 2 mm on the surface (mainly caused by secondary normalizing + tempering, resulting in surface decarburization) when directly inspecting the valve casting body, and seamless steel pipes shall also be taken from less than 1 mm on the surface. There is no such limitation for metallographic sampling.

.jpg)