Filling process is one of the main contents of sand casting process. Complex physical and chemical phenomena such as heat transfer and oxidation will occur in the filling process. The filling process is a complex process, which involves many complex mathematical models. The numerical simulation method can simulate the flow state and heat transfer phenomenon of liquid metal in the mold filling process, analyze the change laws of liquid metal flow velocity and temperature, improve the pouring scheme according to these laws, and predict the casting defects such as insufficient pouring and cold shut.

1) Definition of fluid

Fluid is composed of a large number of molecules that are constantly moving thermally and have no fixed position, including liquid and gas. Its basic feature is that it does not have a certain shape and has fluidity. Friction occurs between adjacent particles when liquid flows.

(1) Constant flow and unsteady flow

The flow that changes with time is called unsteady flow, and the flow that does not change with time is called constant flow. Treating a certain flow as a constant flow or an unsteady flow needs to be distinguished according to specific occasions. For example, turbulence belongs to unsteady flow from a micro point of view.

(2) Laminar and turbulent flow

Laminar flow is a kind of flow in which the particles of fluid move in a smooth straight line and parallel to the pipe axis. Turbulence is a kind of flow in which the moving directions of particles are mixed with each other. Generally, it can be determined whether it belongs to turbulent flow or laminar flow according to the critical Reynolds number. Reynolds number is the ratio of inertial force to viscous force. It is generally considered that turbulence occurs when Reynolds number is greater than a certain critical value.

2) Compressibility and thermal expansion of liquids

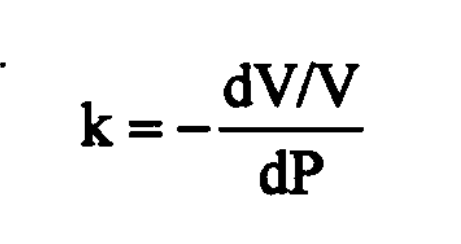

The compressibility of liquid refers to the characteristic that the volume of liquid becomes smaller when it is under pressure around it. The compressibility of liquid can be expressed by volume compressibility coefficient K, which refers to the volume of liquid that decreases relatively when the unit pressure increases when the temperature remains unchanged, which can be expressed as:

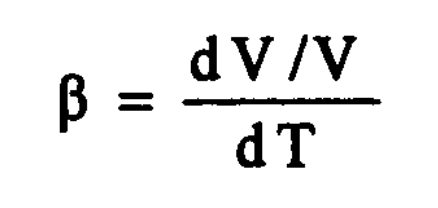

The thermal expansion of the filling liquid of sand castings refers to the characteristic that the volume of the liquid increases when the temperature increases. The thermal expansion of the filling liquid of sand castings can be determined by the coefficient of thermal expansion β The specific expression is:

Where:

K – Volumetric compressibility coefficient;

V – volume;

P refers to pressure;

T – temperature.

It is found that under the conditions of 0 ° C and 0.5MPa, the volume of water will decrease by about 0.5/10000 when the pressure increases by 0.1MPa, and the volume will increase to 1.5/10000 when the temperature increases by 1 ℃ at 10.20 ° C. Therefore, water is considered as an incompressible liquid in engineering, and when the thermal expansion of the liquid is not considered, other liquids can also be considered as incompressible.