This article focuses on the analysis and improvement of nitrogen porosity defects in gray iron castings produced by the iron-mold sand-coated casting process. Through qualitative and quantitative analysis using EDS spectrometer and combined with the casting production process, the formation reasons of nitrogen pores are explored. Measures such as improving the quality of coated sand, adjusting the production process, and separating the recycled sand of different production lines are taken to reduce the risk of nitrogen porosity defects. The improved process has achieved good results in continuous production, providing valuable experience for the improvement of casting quality.

1. Introduction

The iron-mold sand-coated casting process has its own advantages in producing castings, such as enabling the castings to have dense structure and high mechanical properties. However, in the production of automotive brake drum castings by a certain iron-mold sand-coated process, there appeared batch outer circle casting defects, mainly concentrated in the upper corner of the large outer circle of the brake drum. Understanding and solving these defects are crucial for improving the quality of castings and meeting the requirements of product performance.

2. Casting Process

2.1 Melting and Molding Process

- The casting production uses a medium-frequency induction electric furnace. The charge materials include scrap steel (60% – 70%) and the rest is return scrap, which includes gating systems and machining scraps. The scrap steel has certain quality requirements, such as ω(C) > 98%, ω(S) ≤ 0.5%, ash content ≤ 2%, and volatile content ≤ 1%, with a particle size of 1 – 5 mm.

- The charging sequence is to add 50% return scrap (iron filings) at the bottom of the furnace, then 70% carburant, and then add the scrap steel. During the addition of scrap steel, the remaining 30% carburant is added twice into the furnace.

- The melting temperature is controlled at 1500 – 1530°C, and high-temperature standing for 5 minutes and repeated slagging are carried out at 1530 – 1550°C. The iron liquid tapping temperature is 1490 – 1530°C. When tapping, 75″ ferrosilicon is used for inoculation treatment. The pouring temperature of the last piece is not lower than 1360°C, and the whole package pouring time does not exceed 15 minutes.

- The old sand used is regenerated coated sand, and the new sand is Inner Mongolia Tongliao sand. The coated sand adopts a hot regeneration process, and its main process includes steps such as old sand crushing, screening, magnetic separation, hot regeneration, removing fine powder, cooling, storage, and inspection. The coated sand has certain performance requirements, such as a room temperature tensile strength ≥ 2.5 MPa, room temperature bending strength ≥ 6 MPa, hot state tensile strength ≥ 1.3 MPa, hot state bending strength ≥ 3.8 MPa, burning loss ≤ 2.6%, and gas evolution ≤ 20 mL, with a melting point of 95 – 110°C. The new sand addition amount is 5% – 20%, and the rest is recycled sand.

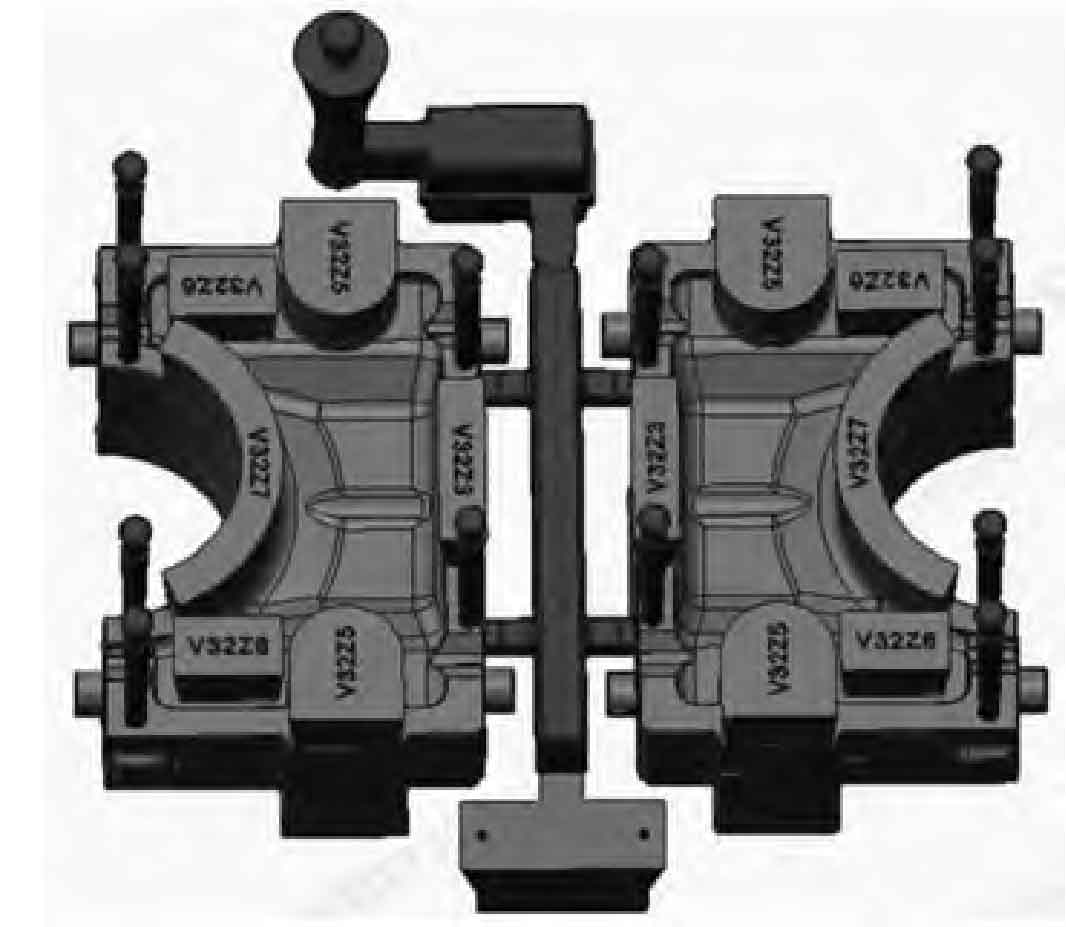

2.2 Gating System

- The runner width is the same as the inner gate width. The thickness is determined according to the flange wall thickness of the casting. The pouring cup adopts a funnel shape. The pressure angle in the pouring cup is not less than 40°. A 15PPI ceramic filter is placed in the pouring cup.

- A semi-closed gating system is used, with ∑S_inner: ∑S_gate: ∑S_runner = 1:4.17:2.04. According to the product structure, 4 or 5 inner gates are set. The cross-sectional area of a single inner gate is not less than 240 mm². The single-mold pouring time of the casting does not exceed 25 seconds. There are two stress grooves on each side of the upper and lower parts of the inner gate.

3. Defect Analysis

3.1 EDS Energy Spectrum Analysis

The defect area shows irregular shapes with dendritic crystals. The defect is perpendicular to the casting surface and penetrates 2 – 5 mm into the casting. The EDS analysis shows that the elements in the defect area include C, N, Fe, O, and Si. The content of N is relatively high, which is an important indication of nitrogen porosity defects.

3.2 Nitrogen Porosity Formation Mechanism

Nitrogen in the iron liquid forms an interstitial solid solution. During the solidification process of the iron liquid, as the temperature decreases, the solubility of nitrogen also decreases. In the iron-mold sand-coated casting process with a fast cooling rate, the surface iron liquid solidifies quickly, and the nitrogen gas cannot be smoothly discharged, resulting in the formation of nitrogen porosity defects.

3.3 Nitrogen Porosity Generation Cause Analysis

- Material Sources of Nitrogen:

- Scrap Steel: Different types of scrap steel have different nitrogen contents. For example, the nitrogen content in ordinary carbon steel and high manganese steel is about 40 – 60 ppm, in threaded steel is about 90 ppm, and in guide rail steel is about 110 – 120 ppm.

- Carburant: Different types of carburants also have different nitrogen contents. Coal-based carburants have a nitrogen content of about 2000 – 7000 ppm (0.2% – 0.7%), ordinary calcined petroleum coke carburants have a nitrogen content of about 1000 ppm, high-temperature calcined petroleum coke carburants have a nitrogen content of 300 – 500 ppm, and graphitized carburants have a nitrogen content of not more than 300 ppm.

- Coated Sand: The resin in the coated sand contains a certain amount of nitrogen. In the production formula, the resin addition amount is 2% – 2.5% of the original sand mass. Urotropine, which is widely used as a curing agent and accounts for 15% of the resin mass, contains 40% nitrogen in its mass. After calculation, the nitrogen content in the coated sand is about 0.12% – 0.15%, which may lead to nitrogen porosity defects in castings.

4. Improvement Measures

4.1 Coated Sand Quality Improvement

- Select High-Quality Raw Materials: Choose phenolic resin and urotropine with better quality to reduce the nitrogen content in the coated sand and lower the risk of nitrogen porosity defects.

- Increase New Sand Addition Amount: Adjust the new sand addition amount from 5% – 20% to 20% – 40% to reduce the residual nitrogen content in the recycled sand.

- Separate Recycled Sand of Different Production Lines: Since the coated sand performance requirements, sand particle size, and new sand addition amount are different for different production lines, separating the recycled sand can avoid process problems caused by mixing.

4.2 Production Process Improvement

- Increase Exhaust Channels: Add exhaust plugs to increase the exhaust channels, which is beneficial for the gas discharge during the curing of the coated sand and the filling of the coated sand, and improves the sand shooting quality.

- Adjust Temperature Settings: Set the mold temperature at 230 – 250°C and the iron mold temperature at 240 – 280°C. This is because urotropine in the coated sand decomposes 大量 at 230°C and above. Adjusting the temperature can accelerate the gas evolution of the coated sand and is conducive to the discharge of gas.

- Extend Curing Time: Extend the curing time from 8 – 20 minutes to start the pouring time from 10 minutes to not less than 20 minutes, which is beneficial for the gas in the iron liquid to float up and reduces the formation of casting porosity defects.

5. Results and Discussion

After implementing the above improvement measures, continuous production was carried out. More than 100,000 products were produced, and no nitrogen porosity defects occurred. This shows that the improvement measures are effective in solving the nitrogen porosity defect problem. The adjustment of coated sand quality and the optimization of the production process have significantly improved the quality of the castings. The separation of recycled sand of different production lines has also ensured the stability of the process. The increase in exhaust channels, adjustment of temperature settings, and extension of curing time have effectively promoted the discharge of gas and reduced the occurrence of porosity defects.

6. Conclusion

In this study, through comprehensive analysis and a series of improvement measures, the problem of nitrogen porosity defects in iron-mold sand-coated gray iron castings has been effectively solved. The selection of high-quality coated sand raw materials, the increase in new sand addition amount, and the separation of recycled sand have improved the quality of the coated sand. The adjustments in the production process, such as increasing exhaust channels, optimizing temperature settings, and extending curing time, have enhanced the gas discharge ability and improved the casting quality. These measures provide valuable references for the production of similar castings and contribute to the improvement of the overall quality of the casting industry. Future research can further explore the optimization of the casting process and the development of new materials to continuously improve the quality and performance of castings.

7. Future Perspectives

The successful resolution of nitrogen porosity defects in iron-mold sand-coated gray iron castings opens up several avenues for future research and development in the casting industry.

7.1 Further Optimization of Coated Sand Formulation

Although the current improvement measures have significantly reduced the occurrence of nitrogen porosity defects by adjusting the coated sand quality, there is still room for further optimization of the coated sand formulation. Future research could focus on exploring alternative resins and curing agents with lower nitrogen contents or better gas release properties. Additionally, investigating the optimal combination of different additives in the coated sand to balance its performance in terms of strength, gas evolution, and other characteristics could lead to more reliable and high-quality casting results.

7.2 Advanced Process Monitoring and Control

Developing more advanced process monitoring and control systems can help in real-time detection and prevention of potential defects. For example, using sensors to monitor the temperature, gas pressure, and composition during the casting process can provide valuable data for timely adjustment of process parameters. This could further enhance the quality consistency and reduce the defect rate of castings. Moreover, integrating artificial intelligence and machine learning algorithms with the process monitoring system could enable predictive maintenance and process optimization, improving the overall efficiency and quality of the casting production.

7.3 Study on the Interaction between Different Defect Mechanisms

In actual casting production, multiple defect mechanisms may interact and affect each other. Future studies could delve into the interaction between nitrogen porosity defects and other common casting defects such as shrinkage porosity, hot tearing, and oxide inclusions. Understanding these interactions can help in formulating more comprehensive and effective prevention and control strategies. For instance, the influence of the cooling rate and solidification sequence on the formation and distribution of different defects needs to be further investigated to optimize the casting process and improve the overall quality of the castings.

7.4 Expansion to Other Casting Processes and Materials

The knowledge and experience gained from solving nitrogen porosity defects in iron-mold sand-coated gray iron castings can be extended to other casting processes and materials. For different casting methods like die casting, investment casting, or sand casting using different types of alloys, the principles and strategies for defect prevention and control may vary. However, the fundamental approach of analyzing the defect formation mechanism, identifying the source of defects, and implementing appropriate improvement measures remains applicable. By applying the learned lessons to a broader range of casting scenarios, the overall quality and performance of the casting industry can be further improved.

7.5 Environmental and Sustainability Considerations

With increasing concerns about environmental protection and sustainable development, the casting industry also needs to adapt. Future research can explore ways to reduce the environmental impact of the casting process while maintaining or improving the quality of castings. This may involve developing more environmentally friendly coated sand materials with lower emissions and waste generation, optimizing the recycling and reuse of materials in the casting process to reduce resource consumption, and improving the energy efficiency of the casting equipment. For example, researching on the use of renewable materials in coated sand or developing new recycling technologies for waste sand can contribute to a more sustainable casting production.

In conclusion, the analysis and improvement of nitrogen porosity defects in iron-mold sand-coated gray iron castings is an important step in enhancing the quality and performance of castings. By continuously exploring and innovating in various aspects such as coated sand formulation, process control, defect mechanism research, and environmental sustainability, the casting industry can move towards a more advanced and sustainable future, meeting the increasing demands for high-quality cast products in various fields.