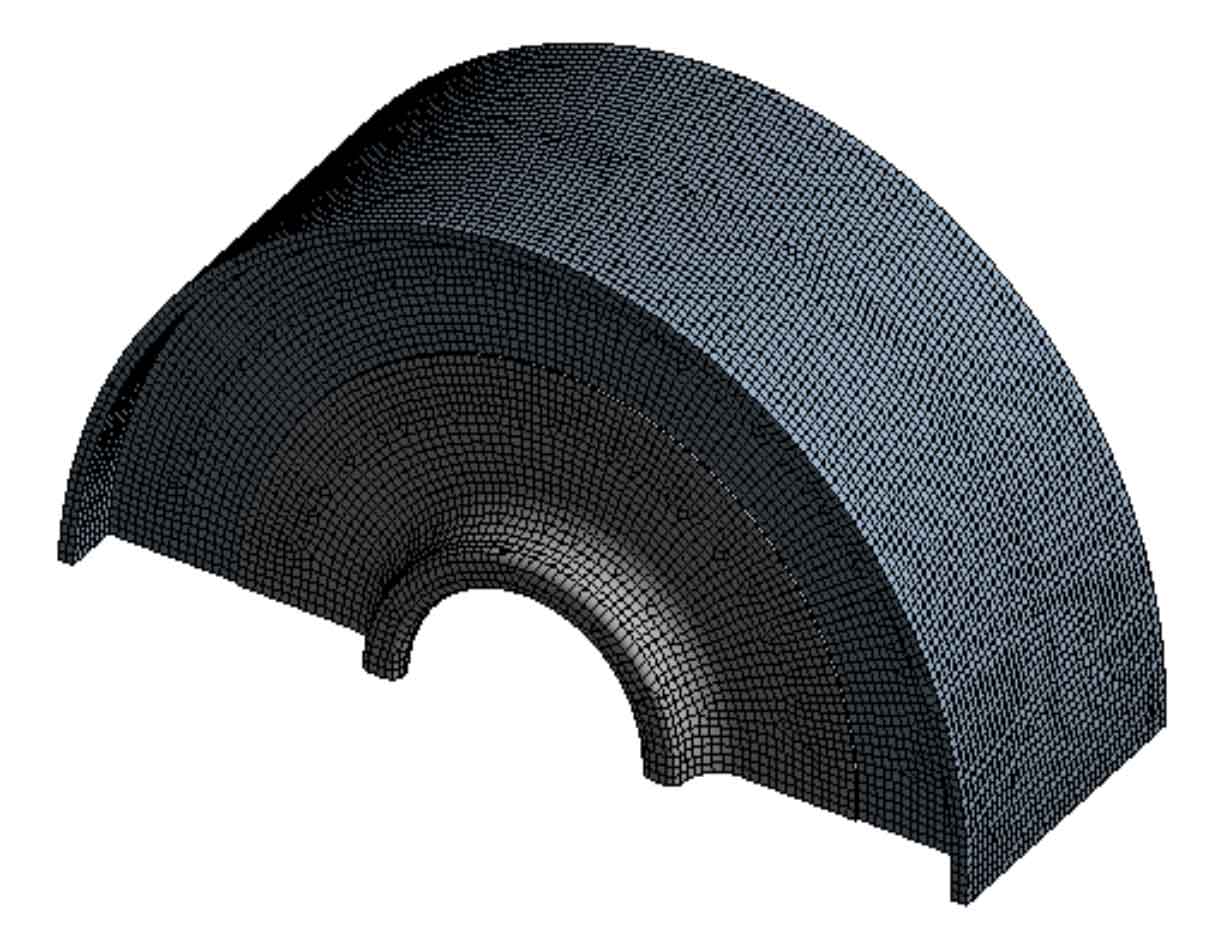

In view of the casting defects of the compressor diaphragm in the casting process, the mechanical properties of the casting diaphragm after cutting and repair welding were analyzed using professional finite element analysis tools. The following conclusions are obtained through analysis:

(1) By analyzing the casting diaphragms under different working conditions, the dangerous working conditions of casting diaphragms were determined.

(2) Through the analysis of the mechanical properties of the casting diaphragms before and after repair welding under dangerous working conditions, the variation rules of the equivalent stress, radial deformation and axial deformation of the casting diaphragms were understood under different cutting and repair welding thicknesses.

(3) According to the operation requirements of casting diaphragms, the maximum cutting and repair welding thickness of casting diaphragms is determined through comprehensive evaluation of the analysis results, which provides technical guidance for further treatment of diaphragms containing casting defects. It provides a reference for the analysis and treatment of similar problems of spacer plate, and saves manufacturing costs for enterprises.