In the actual production process, it is found that the processed casting sand mold has the following two main defects:

(1) Pit defects on the surface of casting sand mold

As shown in Figure 1, irregular pits appear on the surface of the cast sand mold after processing. Through analysis, there is loose sand with viscosity in the pit, and the surface of the loose sand is covered with resin, which is caused by the curing agent in the sand mixing stage and uniform mixing. Because the traditional process is to add the mixed sand into the mold for curing, there are some UN mixed sand in the back sand or the middle part, which will not affect the whole casting sand mold. During the numerical control processing of the casting mold, the middle part of the casting sand mold is likely to eventually become the forming surface of the sand mold. Therefore, it is necessary to ensure that the internal quality of the whole casting sand mold blank is high, and there is no super hard caking or uncured part. It is necessary to increase the mixing time compared with the traditional process to improve the uniformity of resin and curing agent.

(2) Sand accumulation and caking at the bottom of casting sand mold groove

As shown in Figure 2, the groove depth of some processed cast sand molds is shallower than that of the three-dimensional model, and the groove surface is not smooth. After observing and analyzing the processing process, it is because the sand cutting generated in the processing process is accumulated at the bottom of the groove and has not been cleaned up in time by the sand discharge system. The unreacted resin and curing agent on its surface continue to carry out curing reaction, so as to form a certain strength and stay at the bottom of the groove.

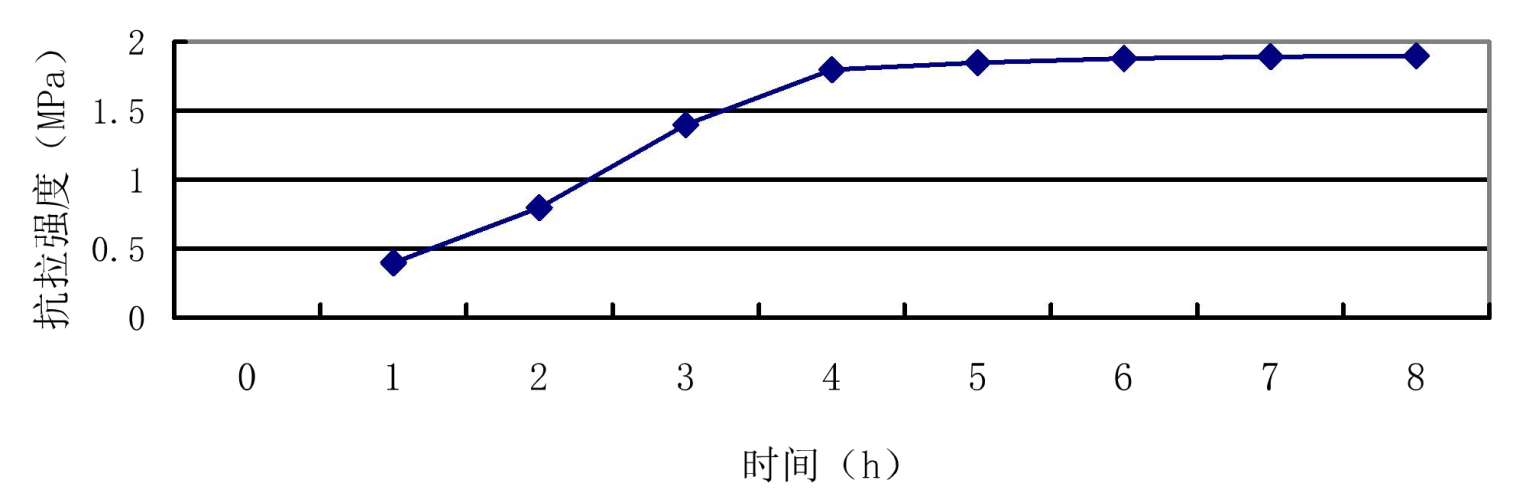

Use self hardening sand to prepare “8” shaped sample, and measure its tensile strength after different curing time. The test results are shown in Figure 3 below. The strength of casting sand mold shows an upward trend from 1 hour to 8 hours after curing. The intensity increases obviously in the first 4 hours, the increase range of intensity from 4 hours to 8 hours is small, and tends to be flat in the later stage. It can be seen from this that if the solidification time of the casting sand mold blank is short, i.e. cutting it, there is the possibility of continuing the solidification reaction after the sand cut and accumulation of the sand mold, resulting in the above casting defects.