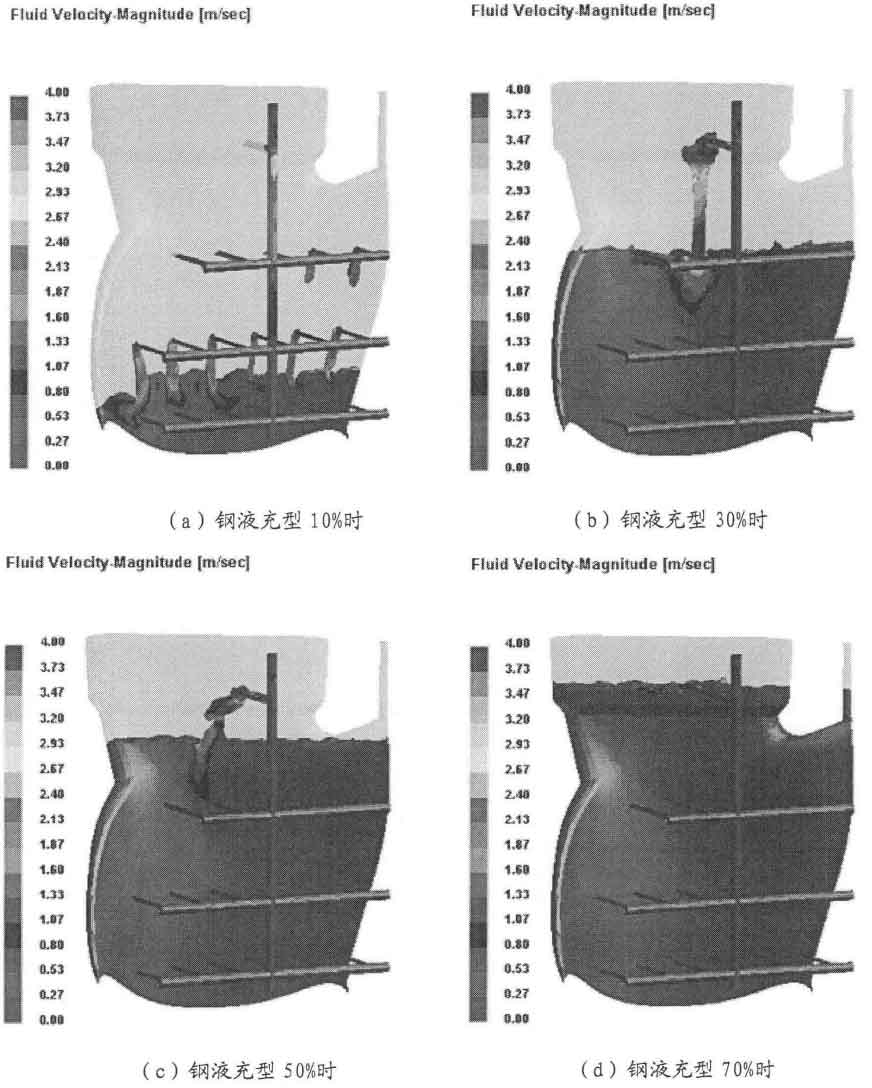

After the pretreatment, the mold filling simulation experiment of blade sand casting will be carried out. The simulation results are shown in figure a-d.

The simulation diagram based on the filling speed is selected, and the speed of liquid steel flow rate is represented by different colors. On the reference speed bar on the left, dark purple at the bottom indicates the slowest flow rate, while dark red at the top indicates the fastest flow rate. The part of blade sand casting that is not filled is indicated by gray.

It is obvious from figure a that the molten metal first enters the mold cavity from the bottom inner sprue, but with the rise of the liquid level, the molten metal does not flow through the inner sprue of each layer from bottom to top, but flows through the inner sprue of each layer at the same time, that is, there is the phenomenon of “random pouring”; The filling speed of molten steel is very fast, the average rising speed of molten steel in the mold cavity is 21.7mm/s, and the molten steel has a certain erosion phenomenon on the sand mold wall.

When the mold filling reaches 30% (see Figure b), the erosion of molten steel on the sand mold wall is more serious. When the filling reaches 50% (see Fig. c) and 70% (see Fig. d), the erosion decreases and the filling tends to be stable.

It can be seen from the simulation results that the “random pouring” phenomenon of liquid steel filling is caused by the unreasonable structural design of the pouring system; Due to the complex curved surface shape of the blade itself, there is a serious phenomenon of liquid steel eroding the mold wall of sand mold casting when using the stepped gating system, and the mold filling is not stable.

The existence of these problems is easy to cause sand holes, pores and oxide inclusions in sand casting castings. Therefore, the traditional stepped gating system is not suitable for blade sand castings. In order to produce high-quality blade sand castings with no or few defects, the gating system must be improved.