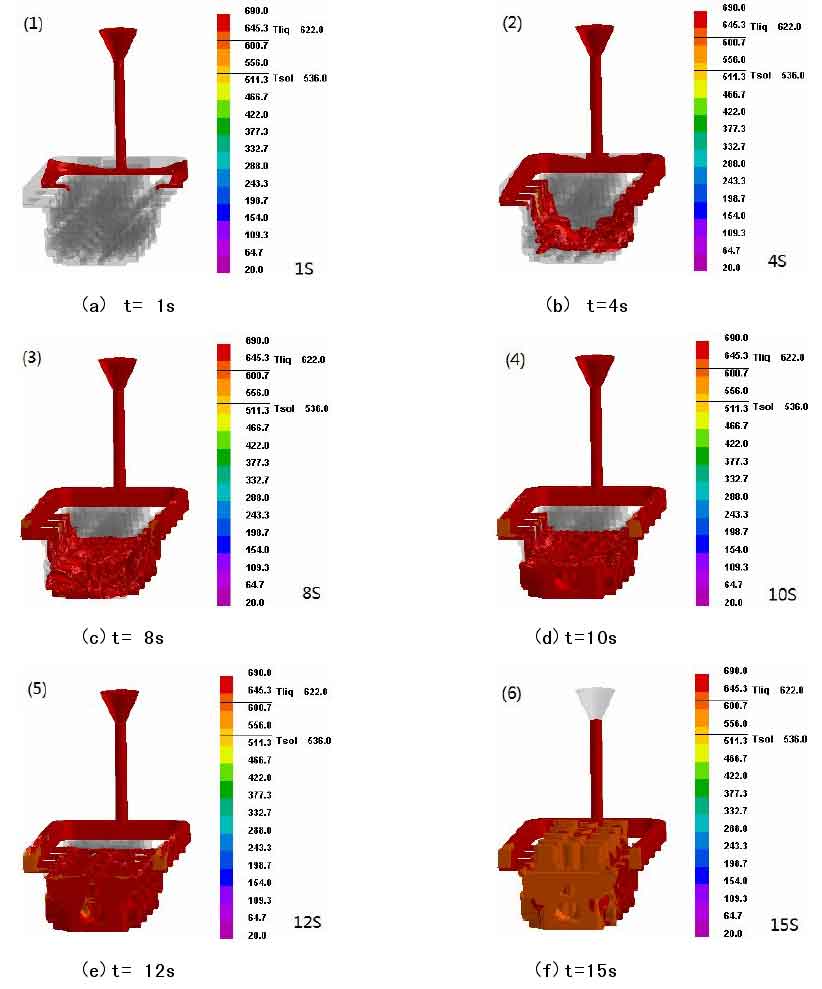

For the second Pouring Scheme of cylinder head, the temperature field distribution of symmetrical top injection inner gate during mold filling is shown in Figure 1. The metal liquid is introduced through 8 symmetrical inner gates at the top. It can be seen from the figure that the metal liquid can smoothly fill the mold cavity without defects such as insufficient pouring, and the filling time of sand casting is about 15s. At the beginning of mold filling, due to the dispersion of the inner gate, the mold filling rate is relatively low. The mold cavity is only filled by 10% in 4S and 25% in 8s, and then the metal speed increases. When the metal liquid filling reaches 10s, the metal liquid at the bottom of the metal liquid is basically at the same level, and then rises slowly and steadily until the mold cavity is filled. The whole sand mold filling process is more gentle than that in front of scheme 1, so there is no obvious turbulence and rolling up. Due to the long runner in the initial stage, the temperature of molten metal decreases rapidly, which is easy to produce defects such as inclusions.

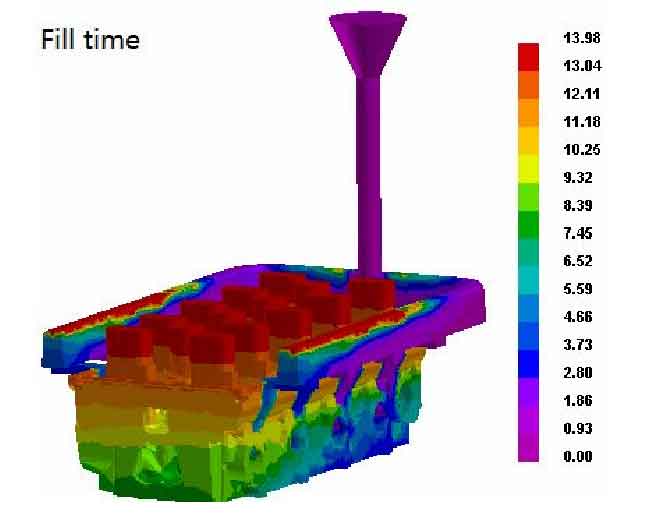

Figure 2 shows the time distribution of symmetrical top injection liquid metal filling each part of the mold cavity. It can be seen that the filling time of the symmetrical position or horizontal position of the whole sand casting is basically different. The filling time of the sand casting close to the gate is relatively short, and the filling time of the whole sand casting occurs relatively horizontally at the last riser of the filling. Therefore, the filling time of sand casting is distributed all the time, resulting in solidification and no symmetrical shrinkage, which is easy to cause defects such as stress concentration. Compared with the first scheme, At the same level, the filling time of gradual sand casting is more different, which makes liquid metal oxidation, miscellaneous slag of sand casting and other defects appear more.