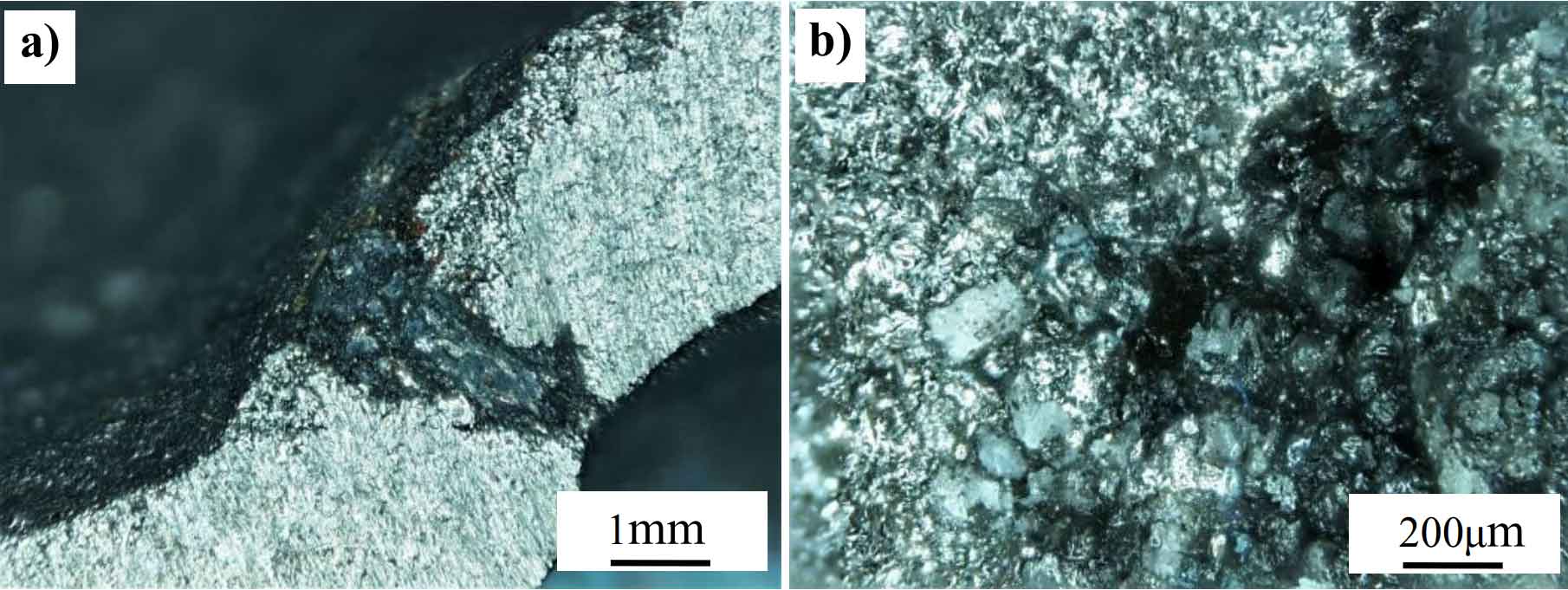

A new type of cylinder block EA888 is a high-end sand casting. Due to its complex structure and wall thickness of 3.5 ± 0.8mm, In order to ensure the forming of cylinder block and reduce sand casting defects The pouring temperature of (air hole, etc.) is about 10 ℃ higher than that of other cylinder blocks, reaching about 1460 ℃. For sand casting to produce thin-walled cylinder blocks, such high pouring temperature leads to prominent sand casting defects such as surface sand sticking and inner cavity sintering. On the one hand, some sand castings cannot be cleaned directly due to sand casting defects such as surface sand sticking and inner cavity sintering Scrap; On the other hand, it is difficult to clean the castings and overstock more than 1000 cylinder blocks. At the same time, due to the serious sand sticking of sand castings, cutting often occurs in machining, resulting in high processing cost and long processing cycle. In the later stage of processing, sand castings have a series of problems such as cylinder hole defects, water leakage, oil leakage and cracks, as shown in Figure 1. The scrap rate of the new cylinder block is more than 5%, the cost of cylinder block parts is high and the production cycle is long, which affects the vehicle assembly.

In order to solve the problems of sand casting defects and surface quality of the new cylinder block, it is necessary to find out what kind of bonded sand EA888 cylinder block is. Therefore, firstly, the types of bonded sand on the surface of cylinder block sand casting are identified.

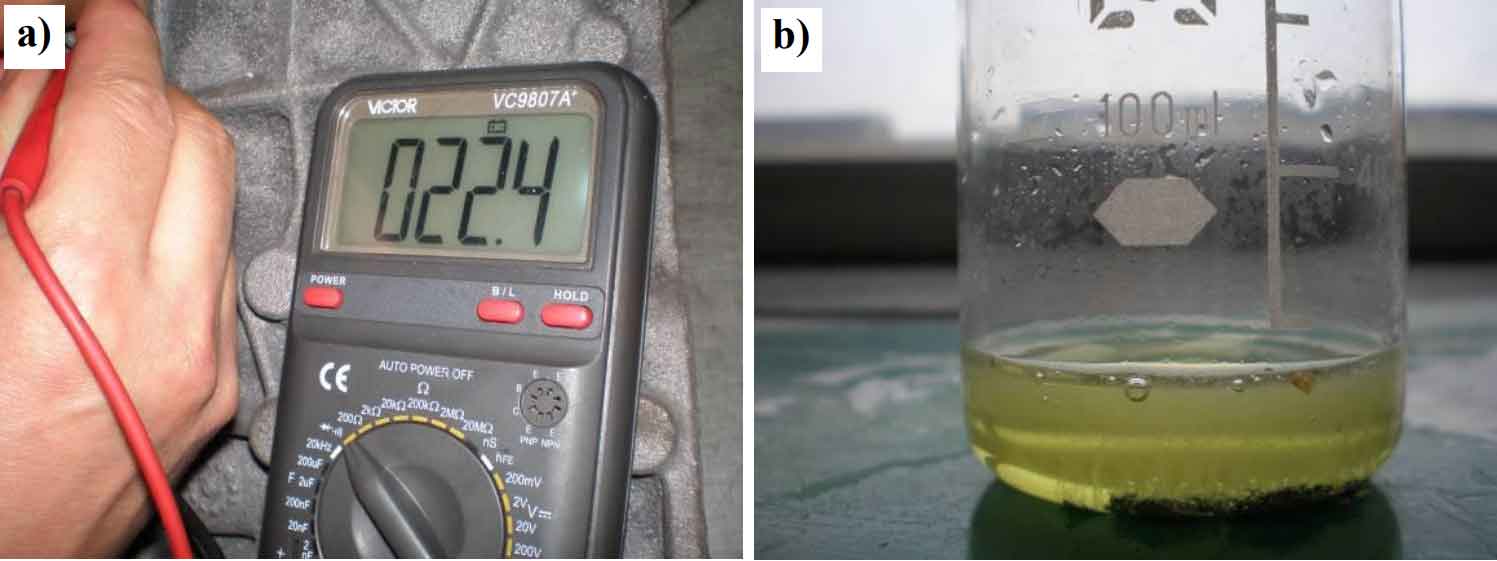

Sand sticking of sand castings can be roughly divided into mechanical sand sticking and chemical sand sticking. We use multimeter measurement method and concentrated hydrochloric acid chemical reaction method to identify them respectively. The two identification methods are shown in Figure 2. The multimeter method is to turn the knob of the multimeter to the resistance measurement gear, and use one electrode to contact the sand casting and the other electrode to contact the sand sticking part. If the resistance is close to zero, it indicates that the bonded sand is the mechanical bonded sand formed by metal wrapped sand particles. If huge resistance is displayed, it indicates that non-conductive ferrous silicate has been formed at the sand sticking part, which belongs to chemical sand sticking. Hydrochloric acid method is to chisel a small piece of sticky sand with a flat shovel and immerse it into a test tube containing concentrated hydrochloric acid. If bubbles occur slowly, the color of the liquid will change from colorless and transparent to brownish red after one night. At the end of the reaction, the bonded sand block disappears, and a few single sand particles are left at the bottom of the test tube, indicating that it is mechanical bonded sand, and the iron part has been dissolved into ferric chloride by hydrochloric acid. Reaction formula: Fe + HCl = FeCl3 + H2. If it is chemically bonded sand, there are few bubbles and there is no obvious change in hydrochloric acid. The final residue is a porous floc.

Using the above method, we selected 100 sand sticking samples from 10 production batches for identification. It is concluded that the probability of sand sticking of EA888 cylinder block is:

(1) Mechanical sand bonding 88%

(2) Chemical bonded sand 5%

(3) Mechanical and chemical mixed bonded sand 7%

From the experimental conclusion, we can conclude that the bonding sand of EA888 cylinder block is mainly mechanical bonding sand, while the chemical bonding sand and mixed bonding sand are only a small part.

Mechanical sand sticking is formed by the infiltration of high-temperature metal liquid into the mold pores. The more and deeper the infiltration of metal liquid, the more serious the mechanical sand sticking is. Mechanical sand sticking not only affects the appearance quality of sand castings, but also causes the scrapping of sand castings. There are many factors affecting mechanical sand bonding, such as uneven sand mold compactness and too large gap between sand particles, resulting in the invasion of liquid metal and the formation of mechanical sand bonding. The forces that promote the infiltration of liquid metal into the pores of the sand mold are mainly the dynamic pressure and static pressure of liquid metal on the sand mold. The greater these two forces are, the easier the liquid metal is to penetrate into the pores of the sand mold. Because the pouring temperature of EA888 cylinder block is higher and the flow capacity of liquid metal is stronger, the dynamic pressure of sand adhesion of sand castings will increase, which will deepen the pores between hot metal and sand particles, thus aggravating the tendency of sand adhesion on the surface of the cylinder block. In addition, there is a bottom pouring gate at the bottom flange of the lower box of the cylinder block, which causes the metal liquid to be in a longer flowable state and the penetration depth will be more prominent. Therefore, the mechanical sand sticking at the lower box flange is more sensitive than other parts.