1.Current process

Due to the serious slag inclusion problem, the white mold material is replaced by stmma, the specific gravity of the white mold is 22-24g / L, and the section size of the inner gate is 8mm × 40mm, cross section 30mm × 45mm, sprue 40mm × 400mm, pouring temperature 1480 ~ 1510 ℃. The slag avoiding net is set in the gating system, and the high aluminum water-based coating is applied for three times with the coating thickness of 1.2-1.5mm. The configuration scheme is shown in Figure 1.

2.Cause analysis of slag inclusion

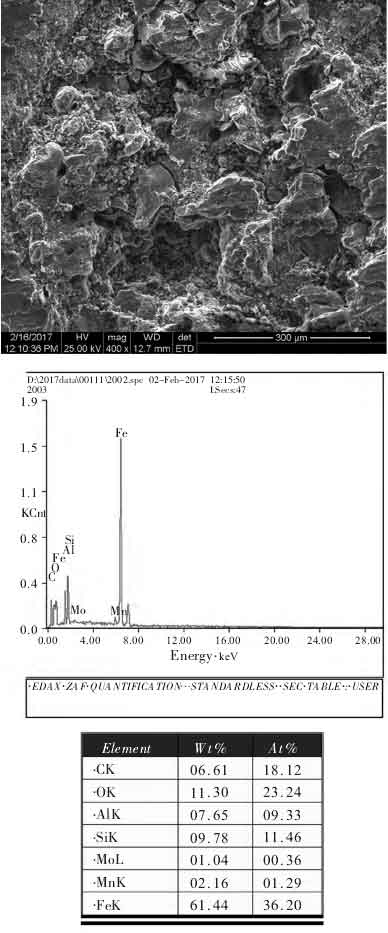

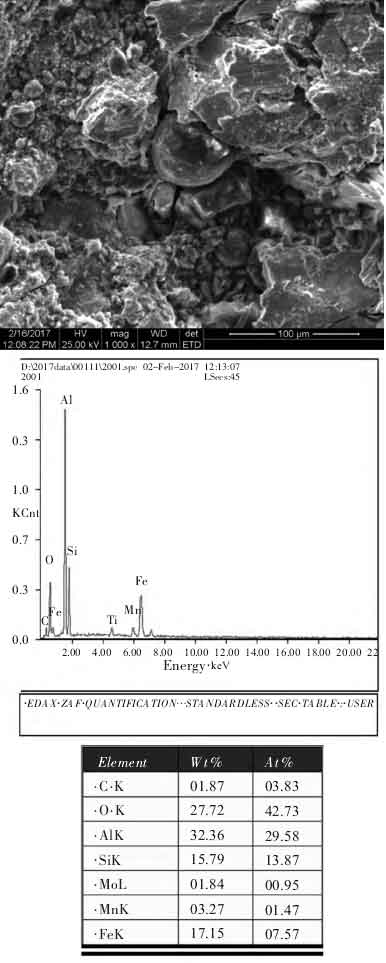

Only through the field research, process research and experience can not accurately determine the composition and type of inclusions, must pass the necessary micro detection means. Therefore, the project team will sample and analyze the defects of different batches and different locations, and the specific locations are shown in Figure 2 and figure 3. The scanning results of electron microscope are shown in Fig. 2 and Fig. 3.

The results show that the contents of Si, Al and Mn in the slag inclusion are high, and the spherical particles appear at the same time, in which the content of Al is as high as 32.36%, indicating that the particles are aluminum compounds; In addition, the manganese content in the defect site is 3-5 times higher than that in the matrix. The coatings used are high aluminum coatings, the main component of which is Al2O3. Therefore, it can be preliminarily inferred that the defects may be caused by insufficient coating strength or fire resistance.

As can be seen from Fig. 3, the diameter of granular material is about 40-60 μ m. The aggregate diameter of the coating is about 40-75 μ m. Therefore, the diameter of granular material is close to that of coating aggregate, which further confirms the inference of defects caused by coating.