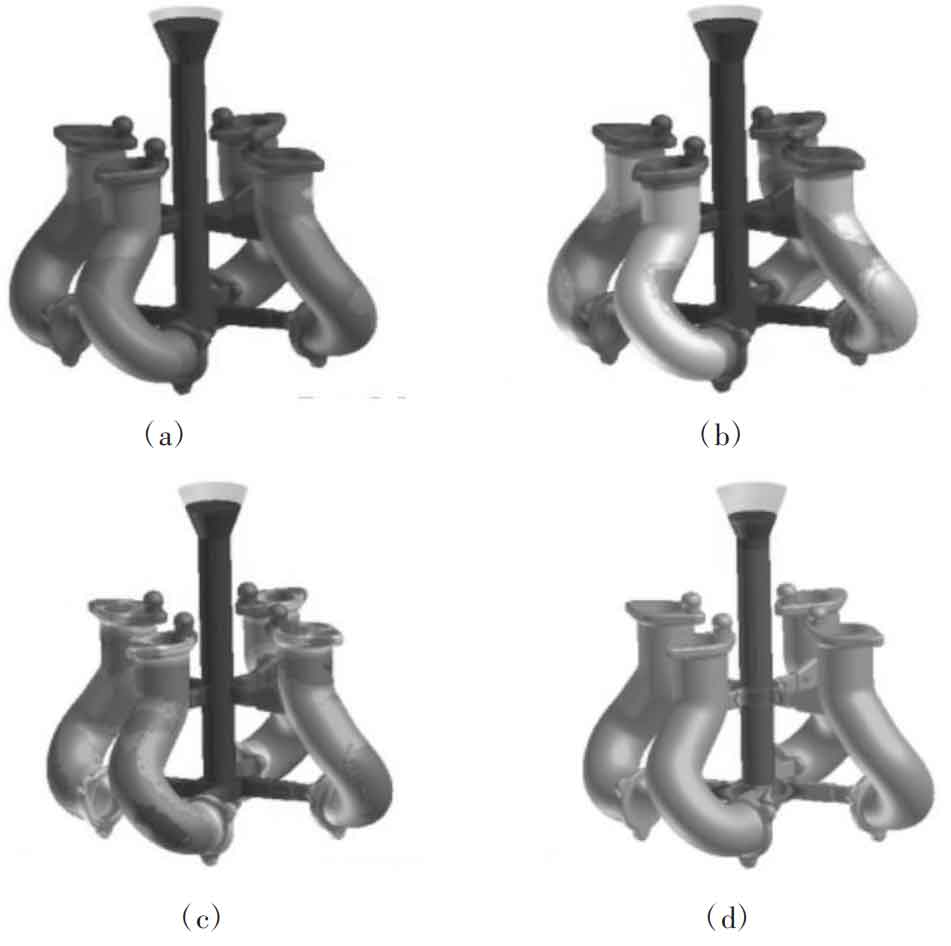

According to the analysis of the above numerical simulation results of lost foam casting, the possible defects and parts in lost foam casting of turbine rear exhaust pipe can be observed through the viewcast module in ProCAST casting simulation software. The following accurately shows the gradual defects according to the porosity and shrinkage criterion of lost foam casting. Figure 1 shows the location and size of insufficient pouring with ProCAST.

The blue area in Figure 2 represents the place where pores appear due to insufficient filling. It can be seen from the figure that the top plane of lost foam casting is insufficient due to the lack of lost foam casting materials. There are pores at the gate Cup due to the solidification shrinkage of the last liquid metal, but the gating system does not belong to the lost foam casting itself, so the defects here can be ignored. The analysis shows that this is because it is difficult to establish the sequential solidification gradient from the feeding end zone to the feeding zone in the lost foam casting process, resulting in shrinkage cavity and porosity in the turbine rear exhaust pipe.