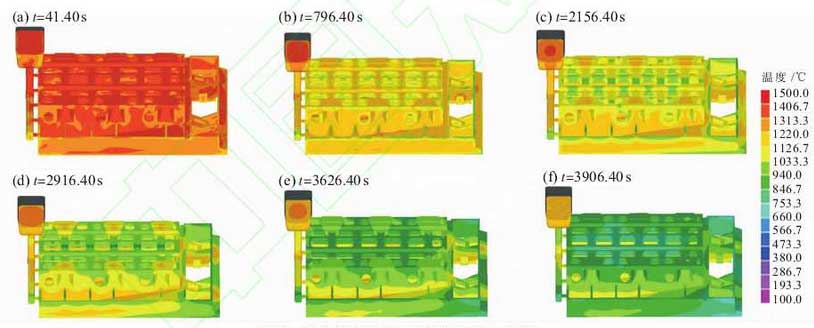

After filling, in order to analyze casting problems such as subsequent solidification defects, the solidification temperature field is further analyzed. The figure shows the temperature field changes during the solidification process of casting metal liquid.From the drawing, it can be seen that the whole part is in simultaneous solidification state at the beginning of solidification, the thin-wall part solidifies preferentially at the end of solidification, and the thick part solidifies finally.

During the process from high temperature to low temperature, the metal will shrink in liquid phase and the whole volume will be reduced. Moreover, during the process of metal solidification, the solidification line will shrink, which is easy to produce defects such as shrinkage and hole shrinkage. However, graphitized expansion exists in grey cast iron.The volume shrinkage caused by cooling will be further offset. According to the analysis of the cooling process of the metal liquid in the figure, there are no obvious defects on the part, so the solid phase ratio of the part needs to be further analyzed.