Casting shrinkage is a complex phenomenon influenced by various factors, including alloy composition. The choice of alloy composition plays a crucial role in determining the shrinkage behavior of castings. This article explores the effects of alloy composition on casting shrinkage behavior and its implications for the casting process.

- Solidification Characteristics: The solidification characteristics of alloys significantly affect the shrinkage behavior. Alloys with a narrow freezing range tend to exhibit reduced shrinkage due to more uniform solidification. In contrast, alloys with a wide freezing range may experience non-uniform solidification, leading to increased shrinkage and the formation of shrinkage defects.

- Solidification Contraction: Different alloys exhibit varying degrees of solidification contraction, which directly impacts shrinkage. Alloys with higher solidification contraction tend to have increased shrinkage tendencies. Understanding the solidification contraction behavior of specific alloy compositions is essential for predicting and controlling shrinkage defects.

- Liquidus and Solidus Temperatures: The liquidus and solidus temperatures of an alloy affect the temperature range over which solidification occurs. Alloys with a narrow temperature range between the liquidus and solidus points tend to exhibit more controlled solidification, reducing the risk of excessive shrinkage.

- Eutectic and Peritectic Reactions: Eutectic and peritectic reactions in alloy systems can influence the shrinkage behavior. These reactions can cause localized shrinkage or volumetric changes during solidification, resulting in the formation of shrinkage defects if not properly controlled.

- Presence of Alloying Elements: Alloying elements can significantly influence the shrinkage behavior of castings. For example, some alloying elements have a solute drag effect, which retards the solidification rate and reduces the risk of shrinkage defects. Other alloying elements may promote the formation of eutectic or intermetallic phases, affecting the overall solidification behavior and shrinkage characteristics.

- Solidification Range: The width of the solidification range affects the solidification rate and the potential for shrinkage defects. Alloys with a narrow solidification range tend to solidify more uniformly, resulting in reduced shrinkage. Alloys with a wide solidification range may experience non-uniform solidification, leading to increased shrinkage tendencies.

- Microstructure Formation: The microstructure formed during solidification is closely linked to the alloy composition and can influence shrinkage behavior. Certain microstructural features, such as dendritic growth or the presence of segregates, can promote shrinkage defects. Controlling the alloy composition can help achieve a desirable microstructure that minimizes shrinkage defects.

- Thermal Expansion Coefficient: The thermal expansion coefficient of an alloy affects its response to temperature changes during solidification and cooling. Alloys with a higher thermal expansion coefficient may experience higher shrinkage due to greater volumetric changes during cooling.

Understanding the effects of alloy composition on casting shrinkage behavior allows foundries to make informed decisions during alloy selection and process optimization. By considering the solidification characteristics, contraction behavior, temperature ranges, alloying elements, solidification range, microstructure formation, and thermal expansion coefficient, foundries can tailor the alloy composition to minimize shrinkage defects and improve casting quality.

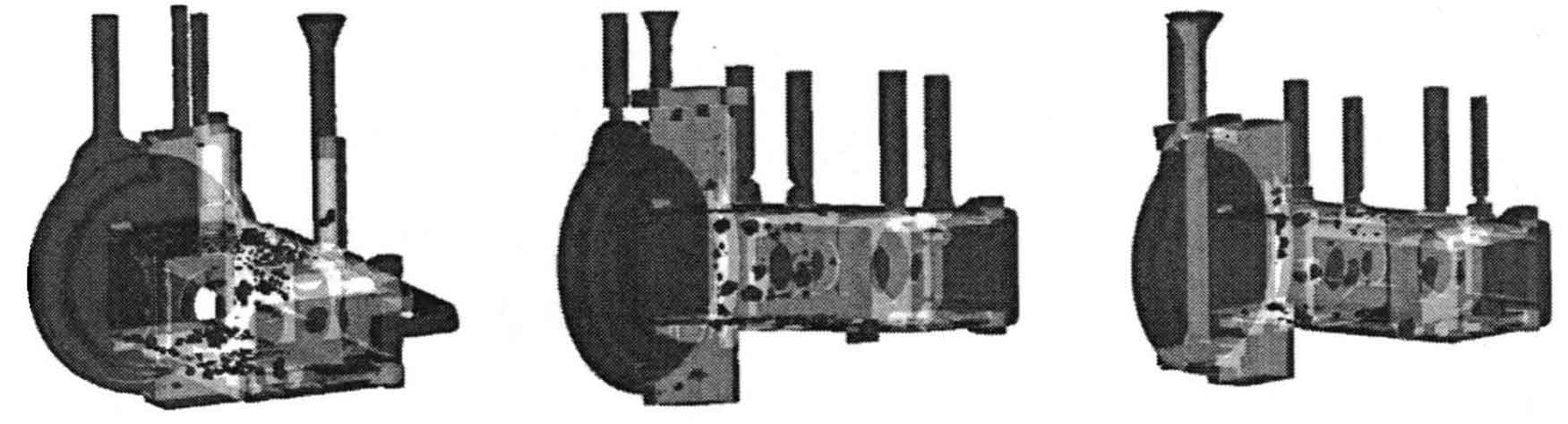

Furthermore, advanced simulation techniques can be employed to model and predict the shrinkage behavior of specific alloy compositions. This helps in optimizing the casting process, including gating and riser design, to ensure proper feeding and minimize shrinkage defects.

In conclusion, alloy composition plays a crucial role in the shrinkage behavior of castings. By carefully considering the effects of alloy composition on solidification characteristics, contraction behavior, microstructure formation, and other relevant factors, foundries can effectively control and mitigate shrinkage defects. Some strategies that can be employed include:

- Alloy Modification: Adjusting the alloy composition by adding alloying elements or modifying their concentrations can help control shrinkage behavior. For example, adding elements with a solute drag effect or promoting the formation of more favorable phases can reduce shrinkage tendencies.

- Optimized Cooling Rate: Controlling the cooling rate during solidification can influence shrinkage behavior. Slower cooling rates can allow for more uniform solidification and minimize shrinkage defects. This can be achieved through proper gating and riser design, as well as the use of insulating materials or cooling media.

- Heat Treatment: Applying appropriate heat treatment processes to the castings can help alleviate residual stresses and reduce shrinkage defects. Heat treatment can modify the microstructure and relieve internal stresses, improving the dimensional stability and reducing the risk of shrinkage.

- Riser Design: Optimized riser design plays a crucial role in feeding the casting and compensating for shrinkage. Properly designed risers can provide a continuous feed of molten metal during solidification, reducing the occurrence of shrinkage defects.

- Process Optimization: Fine-tuning the casting process parameters, such as pouring temperature, mold preheating, and solidification time, can help mitigate shrinkage defects. Process optimization techniques, including computer-aided casting simulation, can provide insights into the optimal process parameters for reduced shrinkage.

- Quality Control and Inspection: Implementing stringent quality control measures and inspection protocols can help identify and address shrinkage defects early on. Non-destructive testing methods, such as X-ray or ultrasound, can detect internal shrinkage defects, enabling corrective actions before further processing or assembly.

- Education and Training: Providing proper education and training to foundry personnel regarding the effects of alloy composition on casting shrinkage behavior is essential. Understanding the interplay between alloy composition, process parameters, and shrinkage defects empowers operators to make informed decisions and take proactive measures to control shrinkage.

By analyzing the effects of alloy composition on casting shrinkage behavior and implementing appropriate strategies, foundries can minimize shrinkage defects, improve casting quality, and enhance overall process efficiency. This allows for the production of high-quality castings with tight dimensional tolerances, meeting the demands of various industries.

As research and technology continue to advance, further insights into the relationship between alloy composition and casting shrinkage behavior will emerge. Continued exploration and development in this area will drive continuous improvement in casting processes and enable the production of defect-free castings with superior dimensional accuracy and mechanical properties.