This article focuses on the application and control of coatings in the casting process. It details the types of coatings used in the company, the verification process of new coatings, the problems encountered during use and corresponding solutions. Through strict control of incoming inspection standards, optimization of application methods and adjustment of procedures, the quality of coatings is ensured to meet production requirements, thereby guaranteeing the stability of casting quality.

1. Introduction

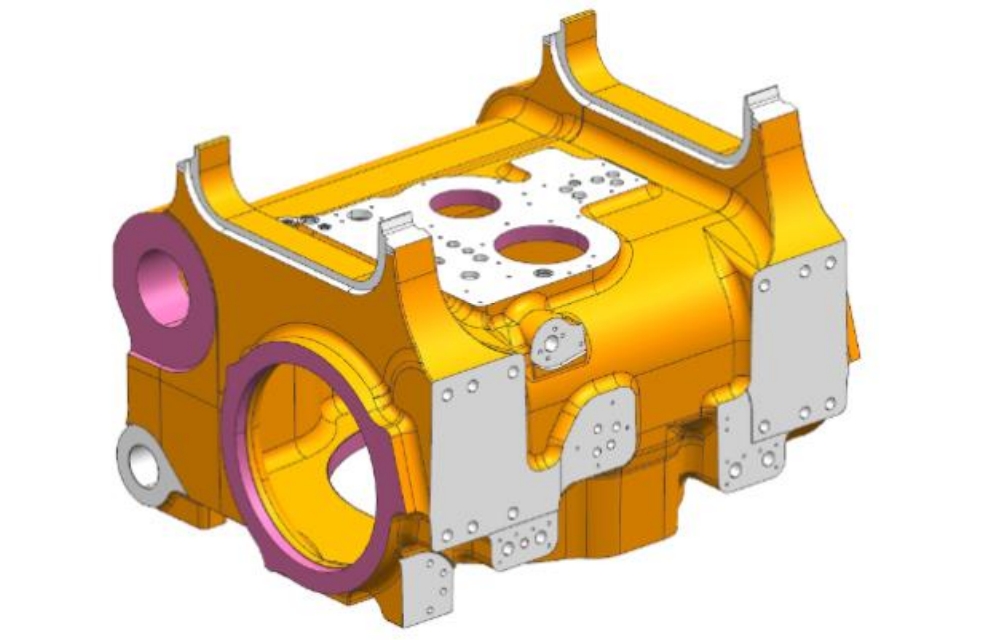

Casting coatings play a crucial role as an essential auxiliary material in the casting process. When the molten metal is poured into the mold cavity and comes into contact with the sand mold and sand core, various physical and chemical reactions occur at the interface between the sand and the molten metal. These reactions may lead to casting defects such as sand sticking, sand holes, and inclusions. Casting coatings are applied to the mold and core to act as a barrier between the molten metal and the substrate, effectively preventing these defects.

The functions of coatings mainly include reducing the surface roughness of castings, preventing or reducing sand sticking defects, and minimizing sand holes and scabbing defects. Coatings can be classified from different perspectives. Based on the solvent, they can be divided into water-based casting coatings and organic solvent-based coatings such as alcohol-based ones. According to their uses, there are casting coatings for steel, iron, non-ferrous metals, flow coating, lost foam casting coating, and die casting coating. In terms of operation methods, they can be classified as dip coating, brushing coating, and flow coating.

2. Coating Application Process in Our Company

2.1 Coating Types

Our company selects different coatings based on the requirements of different products, sand core structures, and process requirements. We use a total of five products from four manufacturers, including water-based and alcohol-based coatings. The application methods are also diverse, including dip coating, flow coating, and brushing coating. Different standards are formulated for different coating application methods:

- Flow coating: Select coatings with good leveling properties, and specify the flow coating angle and improve the surface smoothness of the sand core.

- Dip coating: Adjust the density and angle of dip coating according to different product structures.

- Brushing coating: Only for some weak local positions of the sand core, adjust the density of the brushing coating.

Strict inspection standards are set for the suspension, density, solid content, and gas evolution of different coatings.

| Coating Type | Application Method | Key Requirements |

|---|---|---|

| Water-based coating | Flow coating | Good leveling property, proper flow angle |

| Alcohol-based coating | Dip coating | Appropriate density and angle adjustment |

| – | Brushing coating | Density adjustment for local areas |

2.2 New Coating Verification Process

Since casting coatings have a significant impact on casting quality, it is necessary to verify new coatings before use. Taking the verification of type A dip coating as an example, the process parameters of the sand core dip coating in the core making section are the same as those of other manufacturers’ coatings. The coating density is controlled within the range of 1.28 – 1.36 g/cm³, the drying kiln temperature is set at 200 °C, and the time is 60 minutes. Other core making and casting process parameters remain unchanged.

After production, the casting production process, quality, and subsequent processing rejects are analyzed. For the verified type A dip coating, a total of 36,736 castings were produced, with 58 rejects, and the rejection rate was 0.16%. The main reject defects were sand holes and pores. The rejection rate was within the normal range, the cleanliness of the casting cavity was good, and there was no abnormality in the coating residue after dissecting the castings. Only after passing multiple verifications can the new material be put into use.

3. Problems and Controls in Coating Application

3.1 Abnormal Incoming Coatings

Sometimes, the incoming coatings have high viscosity, which makes it difficult to control the density on site and affects the application of the coating and the quality of the casting. For example, in December 2020, an abnormal dip coating was found. By comparing and analyzing three recent batches of coatings with the manufacturer, the following conclusions were drawn:

- There is no direct correspondence between the viscosity of the coating and its density.

- For coatings with excessive viscosity, adding water to dilute them to prevent coating nodules from causing rejects will reduce the density and affect the high-temperature resistance and anti-sand sticking properties of the coating.

It is believed that the improper temperature control during the production of the coating may cause the coating to be viscous. The carrier liquid in the coating is mainly used to disperse the refractory materials. The amount of the carrier liquid determines whether the coating is in a slurry or paste state.

| Batch Number | Original Density (g/mL) | Original Baume Degree (Be°) | Viscosity Description | Diluted Concentration (g/mL) | Diluted Baume Degree (Be°) | Flow Time through Viscosimeter (s) |

|---|---|---|---|---|---|---|

| 2020122008 | 1.49 | >120 | Viscous | 1.2 | 42 | 15.3 |

| 202012190 | 1.472 | >120 | Viscous | 1.19 | 40 | 14.3 |

| 202012072 | 1.49 | 108 | Normal | 1.16 | 28 | 12 |

3.2 Bubbles in the Coating Tank

After the coating is stirred in the coating tank, there are many bubbles, and bubbles also appear on the casting substrate. The possible reasons are as follows:

- The replacement of the coating exceeds the process range, resulting in coating deterioration.

- The coating substances react with each other.

The solution is to add a defoaming agent.

3.3 Low Coating Strength

After the sand core is dip-coated and dried, the coating may fall off easily. This is mainly due to the abnormal performance of the binder in the coating. The binder has two main functions: one is to effectively bond the refractory materials and other components in the coating to make the coating have a certain strength and wear resistance; the other is to bond the coating to the substrate to protect the substrate.

3.4 Coating Accumulation

During the on-site application process, improper adjustment of the dip coating and coating control methods may cause coating accumulation (airway nodules) and poor coating adhesion in the intake and exhaust ducts. By comparing the positions of the cylinder head airway nodules and the sand core airway, it is found that there is no parting surface and flash. It is analyzed that the improper coating control method and coating density adjustment in the intake airway cause coating accumulation, resulting in excessive material in the sand core and material shortage in the cylinder head airway. By adjusting the dip coating method and changing the coating angle from 30° to 45°, good results are obtained. At the same time, communicate with the coating manufacturer to strictly control the production process and ensure the fluidity of the coating.

4. Use of Special Local Coatings

When castings have water leakage defects, after dissection and analysis, it is found that there are local shrinkage cavities. According to software analysis, there is also a problem of slow cooling in the defective area. In this case, a chilling coating is tested according to the structure of the casting sand core.

The chilling coating contains a strong carbonization element, which can increase the degree of supercooling of the molten metal and make the casting cool quickly. The use of this coating can make the molten iron in this area supercool and solidify quickly, avoiding the accumulation of gas in the sand core and molten iron to form pores. At the same time, it can make the wall thickness structure dense and prevent air leakage during pressure testing. After the test, the painted position is broken off. Macroscopically, a chilled structure with a thickness of about 1.5 mm can be observed. From the metallographic structure analysis, it is found that the structure at the painted position is different from that of normal gray cast iron. The boundary of the white layer is obvious, and obvious supercooled D and E type graphite layers appear, indicating a good chilling effect.

5. Conclusion

Coatings have a very important and complex impact on castings. Through the research on the current application status and problems in the use of coatings, the causes of coating application abnormalities are analyzed. This provides directions for the control of incoming coatings, the handling of abnormal situations, and the verification of new coatings in the future. It is necessary to continuously pay attention to the quality of coatings and improve the control level to ensure the stable quality of castings.

In the future, further research can be carried out in the following aspects: exploring new coating materials with better performance, optimizing the coating application process to improve efficiency and quality, and strengthening the cooperation between coating manufacturers and foundries to jointly promote the development of the casting industry.

In the actual production process, continuous monitoring and improvement of the coating application process are required. For example, establishing a more comprehensive quality monitoring system for coatings, regularly testing the performance of coatings, and quickly responding to problems. At the same time, employees should be trained to improve their understanding and operation skills of coating application to ensure the smooth progress of the production process.

In addition, with the development of technology, new coating application technologies and materials may emerge. Foundries should keep up with the pace of technological development, actively introduce and apply new technologies and materials, and continuously improve their competitiveness in the market.

Overall, the application and control of coatings in the casting process is an important research topic. Through continuous efforts and innovation, the quality of coatings can be better guaranteed, and the quality of castings can be further improved.