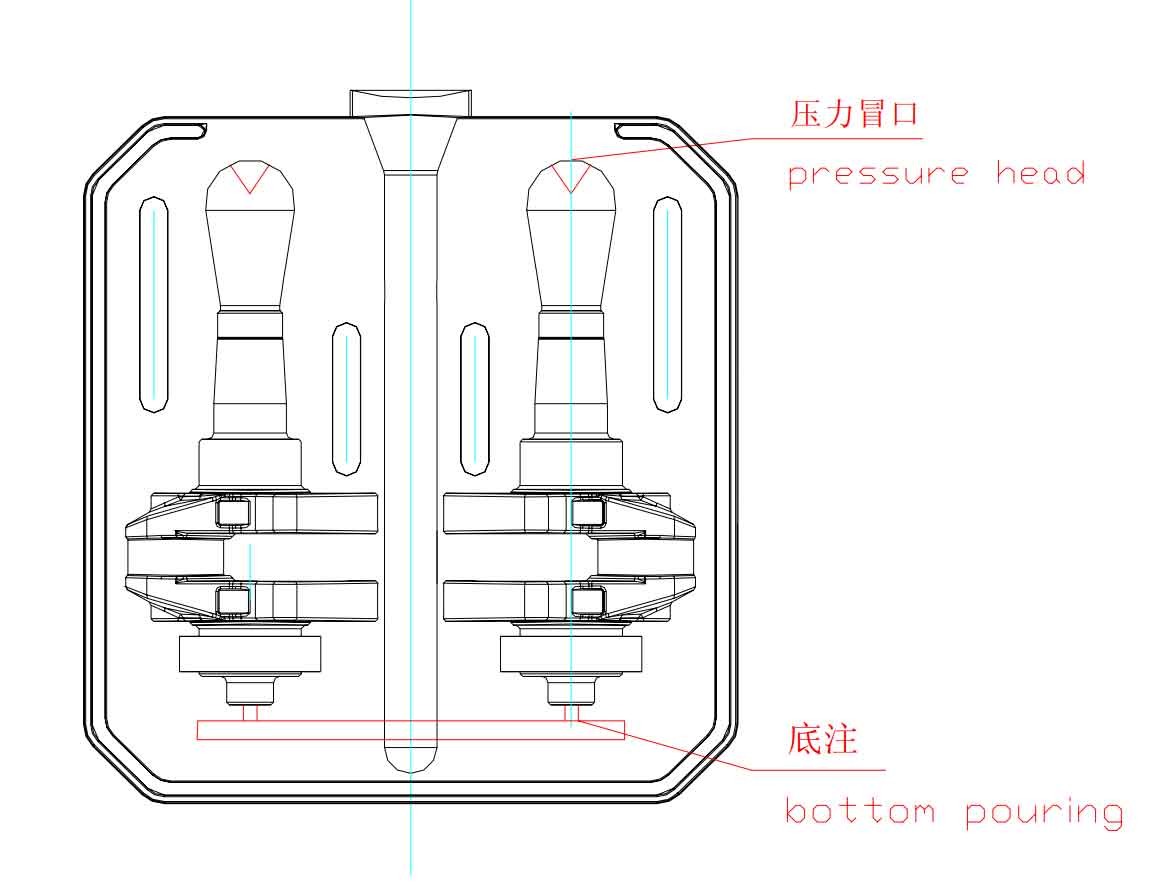

After the development of S1100 diesel engine crankshaft shell casting production, entrusted by other factories, the crankshaft shell casting process was successfully applied to the casting production of knd-5b gasoline engine (5HP) crankshaft. Based on the experience of developing S1100 crankshaft shell mold casting, combined with the structural characteristics of knd-5b crankshaft, that is, there is no oil plug hole clay core at the connecting rod neck. Knd-5b shell crankshaft adopts bottom injection and top riser structure. As shown in the figure.

Basic parameters of the process:

Casting grade: fcd55

Casting weight: 5.7kg;

Riser weight: 2.8-3.0kg;

Weight of gating system: 22.7kg;

Ratio of casting to Riser: 2:1;

Metal yield: 50.22%.