1. lost foam casting vibrating system

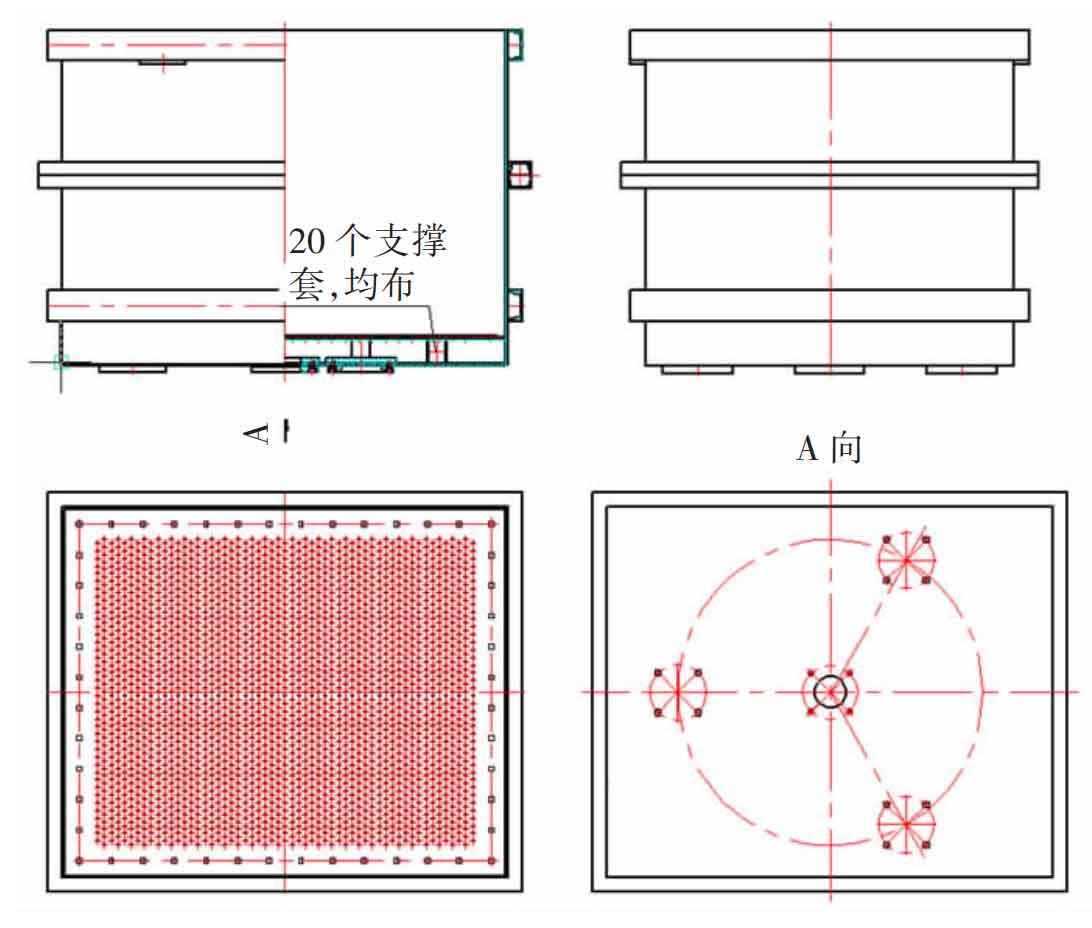

ZHY casting adopts 20 ~ 40 mesh quartz sand and manual bag sand adding method. The size of sand box is 1450mm × 1 200 mm × 1 000mm, and the sand box structure is shown in Figure 1. The lost foam casting vibrating table adopts the lost foam casting vibrating table imitating GK free floating type. The difference is that the motor is suspended on both sides of the lost foam casting vibrating table, with one motor on each side.

2. Existing problems and cause analysis

2.1 Sand sticking of lost foam castings

Due to the weak lateral filling capacity of lost foam casting vibrating table, the compactness of molding sand at the dead corner of yellow mold is low, and the molten iron breaks through the coating to form bonded sand during pouring; In addition, the consistency of sand box is poor, and the vibration acceleration at individual places is different

Up to 3 times, the sand box with low acceleration is very easy to produce sand sticking (as shown in Figure 2), which is not easy to clean, and often leads to the scrapping of lost foam castings.

2.2 Deformation of lost foam castings

In the production of thin-walled lost foam castings such as gearbox side wall and flywheel housing stop, due to the large difference in vibration acceleration at different parts, the maximum difference in acceleration at both sides can reach 2 times, resulting in sand flow in the sand box and pressure deformation of the Yellow mold. Serious visual observation can observe the movement of the Yellow mold in the sand box. After measurement, the amplitude of the sand box is 0.4 ~ 0.7 mm.

The bottom of the sand box used by ZHY casting is supported by 20 support sleeves welded between two layers of 8mm steel plates. In the production process, it was found that the support sleeve began to be desoldered after a period of production, the vibration force after desoldering could not be transmitted upward through the bottom, the compactness of molding sand was low, and the vertical dimension of lost foam castings became larger; At the same time, the bottom plate of the sand box is thin. Due to long-term vibration and impact, the maximum deformation of the bottom plate reaches 2.3 mm. The molding sand in the vertical direction retreats and compacts repeatedly, resulting in the further enlargement of the vertical dimension of lost foam castings. Taking the gearbox middle shell as an example, the theoretical dimension in the height direction is 534 mm, and the actual measured dimension in the height direction is 535.2 ~ 538 mm, resulting in problems such as inconsistent machining allowance and thin hole wall of lost foam castings, and the machining deformation scrap rate is 2.9%.