Tracing the root causes of casting defects is a crucial step in the process of defect analysis and prevention. By identifying and addressing these root causes, foundries can take corrective actions to minimize or eliminate casting defects. Here are some key steps to trace the root causes of casting defects:

- Defect Identification:

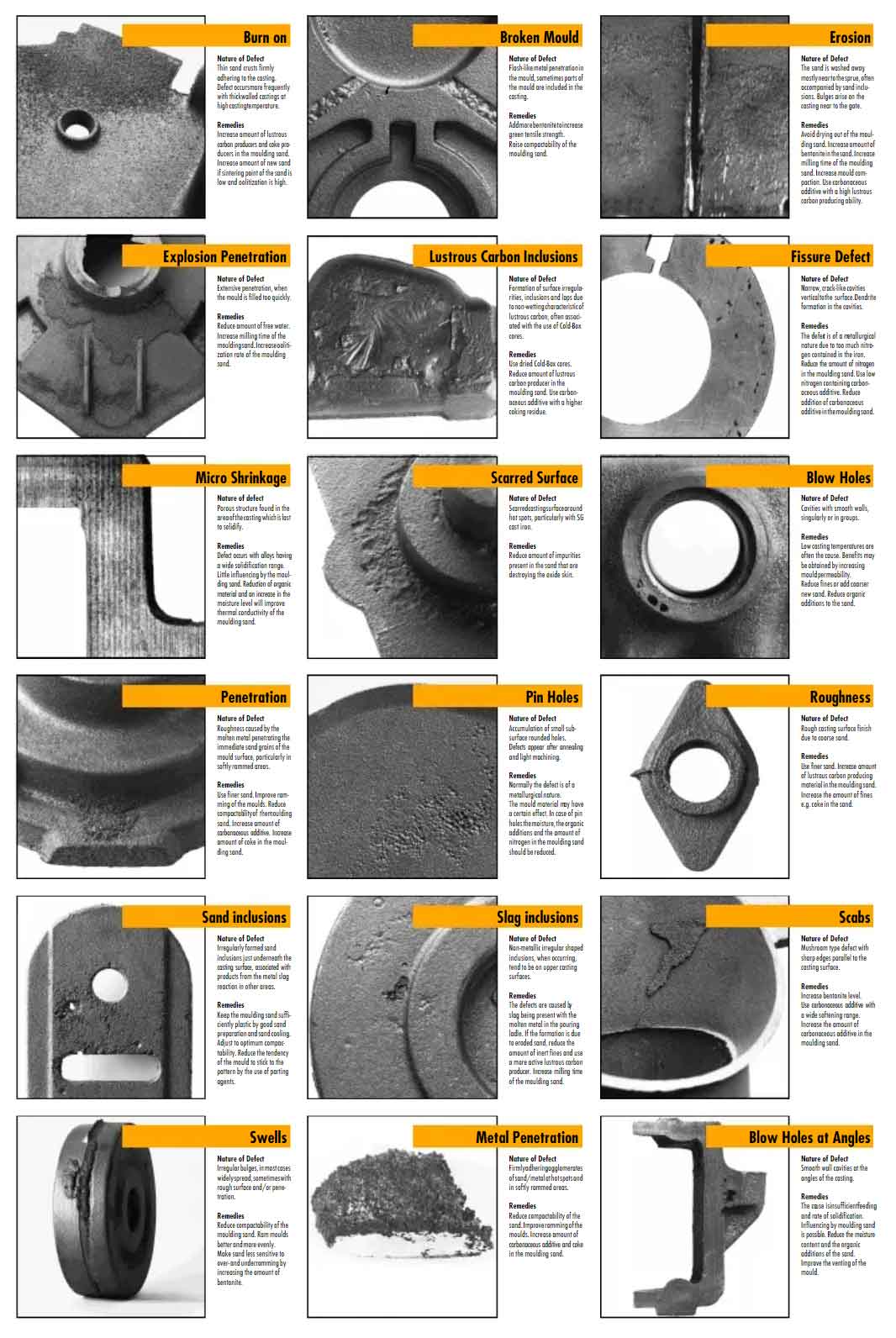

- Visual Inspection: Conduct a thorough visual inspection of the castings to identify any visible defects such as porosity, inclusions, cracks, dimensional deviations, or surface irregularities.

- Non-Destructive Testing (NDT): Utilize NDT methods like X-ray, ultrasonic testing, magnetic particle inspection, or liquid penetrant inspection to detect internal defects that may not be visible.

- Defect Documentation:

- Record and Document Defects: Document the type, location, severity, and frequency of the defects observed. This documentation provides valuable information for further analysis and comparison.

- Process Analysis:

- Review Process Parameters: Analyze the process parameters involved in casting production, including melting, pouring, solidification, cooling, and post-processing steps. Identify any deviations or abnormalities in these parameters.

- Identify Critical Points: Identify critical points in the process where defects are likely to occur. These points may include mold filling, solidification, gating system, mold material, or core preparation.

- Material Analysis: Evaluate the quality and composition of the casting material, including alloys, binders, coatings, and additives. Analyze their impact on the defect formation.

- Process Monitoring: Implement process monitoring techniques such as temperature monitoring, metallographic analysis, or thermal analysis to gather data on process variables and their correlation with defect occurrence.

- Root Cause Analysis:

- Data Collection: Gather relevant data and information from defect analysis, process monitoring, and historical records to identify patterns and trends associated with defect occurrence.

- Statistical Analysis: Utilize statistical tools and techniques to analyze the collected data and identify correlations between process variables and defect occurrence. This helps identify potential root causes.

- Pareto Analysis: Perform a Pareto analysis to prioritize and focus on the most significant defects or root causes that contribute to the majority of the casting defects.

- Cause-and-Effect Analysis: Conduct cause-and-effect analysis (fishbone or Ishikawa diagram) to identify potential causes related to different aspects such as materials, methods, machinery, manpower, measurement, or environment.

- Testing and Validation:

- Hypothesis Testing: Formulate hypotheses regarding the potential root causes based on the analysis conducted. Design experiments or tests to validate these hypotheses.

- Experimental Validation: Perform controlled experiments, process trials, or test castings with modified parameters or materials to determine the impact on defect formation.

- Iterative Improvement: Implement iterative improvements based on the results of experiments and tests. Continuously monitor and evaluate the effectiveness of the implemented changes.

- Documentation and Process Control:

- Documentation: Document the findings of root cause analysis, experiments, and changes implemented to address the identified root causes. Maintain a record for future reference and knowledge sharing.

- Process Control: Develop standard operating procedures (SOPs) based on the established best practices to control and optimize the casting process. Implement quality control measures and process monitoring to ensure consistency and adherence to the defined procedures.

Tracing the root causes of casting defects requires a systematic and analytical approach. By following these steps and continuously improving the casting process based on the findings, foundries can reduce defects, enhance product quality, and increase operational efficiency.