Introduction

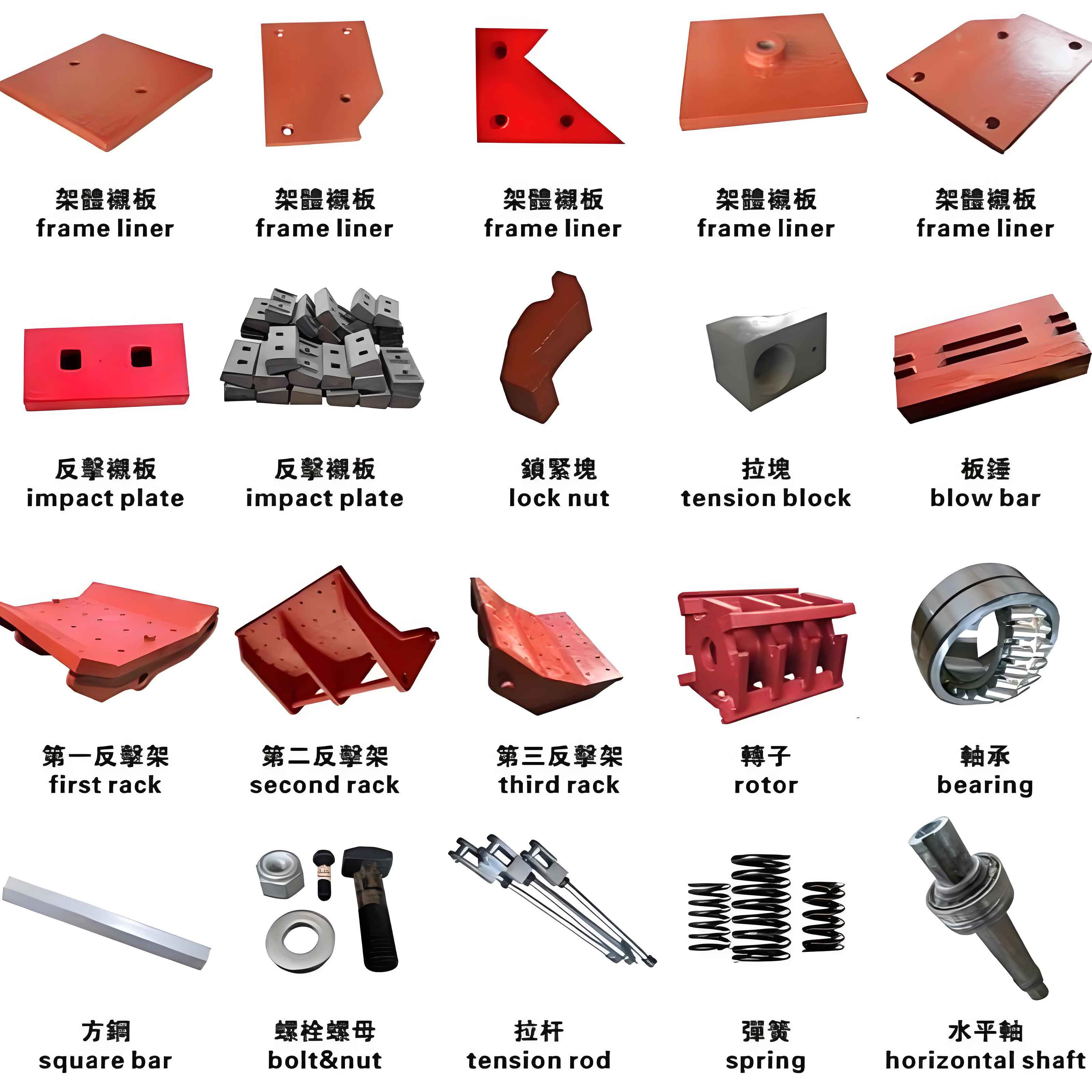

In the fields of quarrying and mining, the Impact Crusher is a vital piece of equipment used to break down rocks and minerals into smaller, more manageable pieces. A crucial component of the Impact Crusher is the blow bar. This article explores the significance of blow bar in quarry and mining applications, examining the materials used, design considerations, common issues, and maintenance practices to ensure their optimal performance.

The Role of Blow Bar in Quarry and Mining

Blow bar is essential in the operation of Impact Crushers, particularly in the rigorous environments of quarrying and mining. They play a pivotal role in crushing various types of rock and ore, transforming them into sizes suitable for further processing or direct use.

Key Functions of Blow Bar:

- Impact Force Generation:

- Blow bar generate the necessary impact force to break down large rocks and minerals.

- This impact force is critical for achieving the desired size reduction.

- Material Fragmentation:

- The repeated strikes by blow bar fragment the material into smaller pieces.

- This fragmentation is essential for further processing stages or final application.

- Wear Resistance:

- Blow bar must resist wear and tear to maintain consistent performance in harsh conditions.

- High wear resistance ensures longer service life and reduces the need for frequent replacements.

Materials Used in Blow Bar

Selecting the appropriate material for blow bar is crucial for maximizing their lifespan and performance in quarry and mining applications. Different materials offer unique properties that cater to various crushing needs.

Common Materials for Blow Bar:

- High Manganese Steel:

- Characteristics: Known for its high toughness and work-hardening properties.

- Applications: Ideal for crushing abrasive materials such as granite, basalt, and hard rock.

- Advantages: Excellent impact resistance and durability.

- Disadvantages: Rapid wear when used with less abrasive materials.

- Martensitic Steel:

- Characteristics: Offers a balance of wear resistance and impact strength.

- Applications: Suitable for medium-hard materials like limestone and dolomite.

- Advantages: Balanced wear resistance and toughness.

- Disadvantages: Not suitable for extremely abrasive materials.

- Chrome Steel:

- Characteristics: High hardness and superior wear resistance due to its chromium content.

- Applications: Best suited for highly abrasive materials.

- Advantages: Long lifespan in abrasive conditions.

- Disadvantages: Brittle and can break under high impact.

- Ceramic Inserts:

- Characteristics: Embeds ceramic inserts within a steel matrix for enhanced wear resistance.

- Applications: Used for extremely abrasive materials such as quartz and silica.

- Advantages: Superior wear resistance and extended lifespan.

- Disadvantages: Higher cost and potential for breakage if not properly manufactured.

| Material | Characteristics | Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| High Manganese Steel | High toughness, work-hardening | Abrasive materials (granite, basalt) | Excellent impact resistance | Rapid wear with less abrasive materials |

| Martensitic Steel | Wear resistance, impact strength | Medium-hard materials (limestone) | Balanced wear resistance, toughness | Not ideal for extremely abrasive materials |

| Chrome Steel | High hardness, wear resistance | Highly abrasive materials | Long lifespan in abrasive conditions | Brittle, can break under high impact |

| Ceramic Inserts | Enhanced wear resistance | Extremely abrasive materials (quartz) | Superior wear resistance, extended lifespan | Higher cost, potential for breakage |

Design Considerations for Blow Bar

The design of blow bar can significantly affect their performance, wear resistance, and impact on operational efficiency in quarry and mining applications.

Shape and Profile:

- Straight Blow Bar:

- Description: Flat and straight design.

- Advantages: Easy to manufacture and replace.

- Disadvantages: Less effective in distributing impact forces, leading to uneven wear.

- Curved Blow Bar:

- Description: Curved profile to improve impact distribution.

- Advantages: Better distribution of impact forces, reducing uneven wear.

- Disadvantages: More complex to manufacture and replace.

- Wing-Tip Blow Bar:

- Description: Extended tips to enhance material penetration.

- Advantages: Improved material penetration and crushing efficiency.

- Disadvantages: Higher wear at the tips, requiring more frequent replacement.

Reinforcement:

- Solid Blow Bar:

- Description: Solid construction for maximum strength.

- Advantages: High durability and resistance to breakage.

- Disadvantages: Heavier, causing increased stress on the Impact Crusher.

- Composite Blow Bar:

- Description: Combination of materials for enhanced performance.

- Advantages: Optimized wear resistance and impact strength.

- Disadvantages: Higher manufacturing cost and complexity.

| Design Aspect | Description | Advantages | Disadvantages |

|---|---|---|---|

| Straight Blow Bar | Flat and straight design | Easy to manufacture, replace | Less effective in impact distribution, uneven wear |

| Curved Blow Bar | Curved profile | Better impact distribution, reduced wear | Complex to manufacture, replace |

| Wing-Tip Blow Bar | Extended tips | Improved penetration, efficiency | Higher wear at tips, frequent replacement |

| Solid Blow Bar | Solid construction | High durability, breakage resistance | Heavier, increased stress on crusher |

| Composite Blow Bar | Combination of materials | Optimized wear resistance, strength | Higher cost, manufacturing complexity |

Common Issues and Maintenance of Blow Bar

Blow bar in quarry and mining applications face numerous challenges due to the harsh conditions and abrasive materials they encounter. Regular maintenance is essential to ensure their longevity and optimal performance.

Common Issues:

- Wear and Tear:

- Continuous impact and friction cause blow bar to wear down over time.

- Solution: Regularly inspect and replace blow bar to maintain crusher efficiency.

- Breakage:

- Blow bar can break if subjected to excessive impact force or if made from brittle materials.

- Solution: Use blow bar made from materials with high impact resistance and ensure proper installation.

- Uneven Wear:

- Uneven wear can result from improper alignment or inconsistent feed material.

- Solution: Ensure proper alignment of blow bar and maintain consistent feed material quality.

Maintenance Practices:

- Regular Inspections:

- Conduct routine inspections to check for signs of wear, cracks, or damage.

- Replace blow bar when wear reaches critical levels to prevent damage to the Impact Crusher.

- Proper Installation:

- Ensure blow bar is correctly installed and secured to avoid movement during operation.

- Follow manufacturer guidelines for installation and torque specifications.

- Material Selection:

- Select the appropriate material for blow bar based on the type of material being crushed and the specific crusher application.

- Use high-quality blow bar to ensure durability and performance.

- Balancing:

- Regularly balance the rotor to minimize vibration and uneven wear on blow bar.

- Ensure that all blow bar is of the same weight and dimensions to maintain balance.

| Issue | Cause | Solution |

|---|---|---|

| Wear and Tear | Continuous impact and friction | Regular inspection and replacement |

| Breakage | Excessive impact force, brittle materials | Use high impact resistance materials, ensure proper installation |

| Uneven Wear | Improper alignment, inconsistent feed material | Proper alignment, consistent feed material |

| Vibration | Unbalanced rotor | Regular balancing, use uniform blow bar |

Impact of Blow Bar on Operational Efficiency

Effective management and selection of blow bar is crucial for maintaining operational efficiency in quarry and mining applications. Key factors include:

- Enhanced Durability:

- Using high-quality materials and designs that resist wear and breakage prolongs the lifespan of blow bar, reducing the frequency of replacements.

- Improved Efficiency:

- Optimally designed blow bar enhance crushing efficiency, reducing the time required to process materials and increasing overall throughput.

- Reduced Maintenance Intervals:

- Regular maintenance and timely replacements prevent unexpected breakdowns, ensuring continuous operation of the Impact Crusher.

- Cost Savings:

- Minimizing downtime through effective blow bar management reduces maintenance costs and increases the return on investment for crushing operations.

| Benefit | Description |

|---|---|

| Enhanced Durability | Longer lifespan, less frequent replacements |

| Improved Efficiency | Faster processing, increased throughput |

| Reduced Maintenance Intervals | Prevents unexpected breakdowns, ensures continuous operation |

| Cost Savings | Lower maintenance costs, higher return on investment |

Conclusion

Blow bar is integral to the efficient operation of Impact Crushers in quarry and mining applications. By selecting the right materials, considering design aspects, and implementing regular maintenance practices, operators can significantly reduce downtime and enhance the performance of their Impact Crushers. Understanding the characteristics and applications of different blow bar materials, such as high manganese steel, martensitic steel, chrome steel, and ceramic inserts, allows for better decision-making and improved crusher performance. Proper management of blow bar leads to enhanced productivity, reduced operational costs, and prolonged equipment life in various crushing applications.