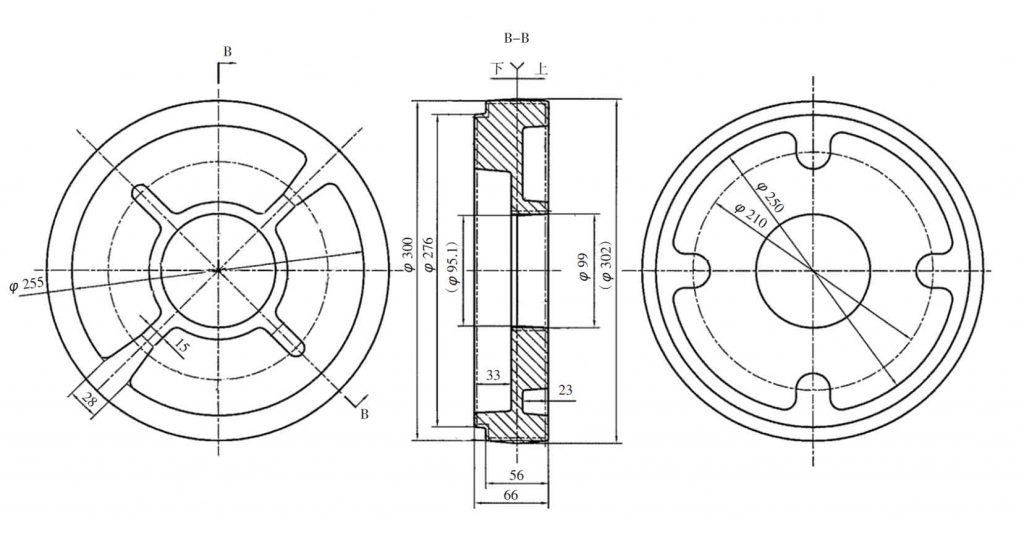

The structure diagram of QT600-3 gear casting produced by ZHY casting is shown in Figure 1, and the overall dimension is φ 302 mm × 66 mm, main wall thickness 56 mm, casting weight 16 kg. The casting is molded with furan resin sand and melted in 1.5 T induction furnace. Q10 pig iron from Longfengshan is used. The recycled materials are the waste nodular iron castings, pouring and riser of our company’s workshop. The scrap steel is the scrap, head and scrap of our company’s carbon steel products. The charge ratio is 30% pig iron + 30% recycled material + 40% scrap steel. The chemical composition is: w (c) 3.6% ~ 3.8% w (SI) 2.3% ~ 2.5%, w (MN) 0.3% ~ 0.5%, w (Cu) 0.5% ~ 0.6%, w (s) ≤ 0.02%, w (P) ≤ 0.07%. The spheroidizing agent qrmg8re3 with the particle size of 10 ~ 30 mm was used for spheroidizing treatment by the punching method, and the addition amount was 1.7%. The inoculant 75sife with the particle size of 5 ~ 15 mm was used, and the addition amount was about 0.7%. Among them, 2 / 3 of the spheroidizing agent was covered, and 1 / 3 of it was inoculated in the ladle during the second tapping. The pouring temperature is 1 400 ~ 1 420 ℃, and the pouring speed is 3.5 ~ 4 kg / s.

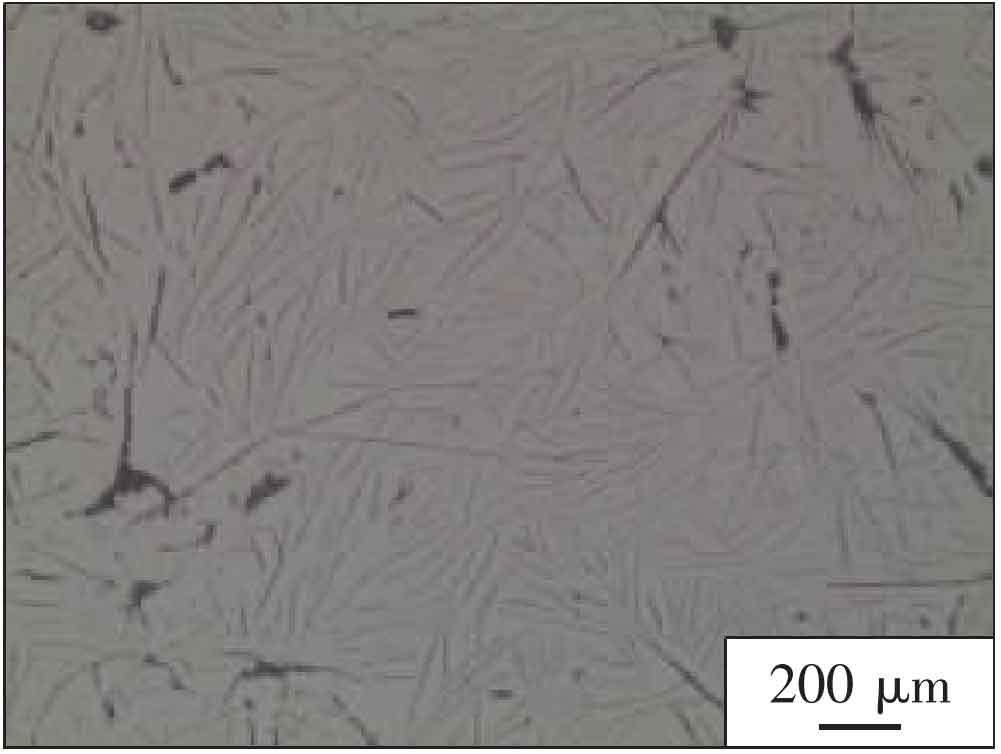

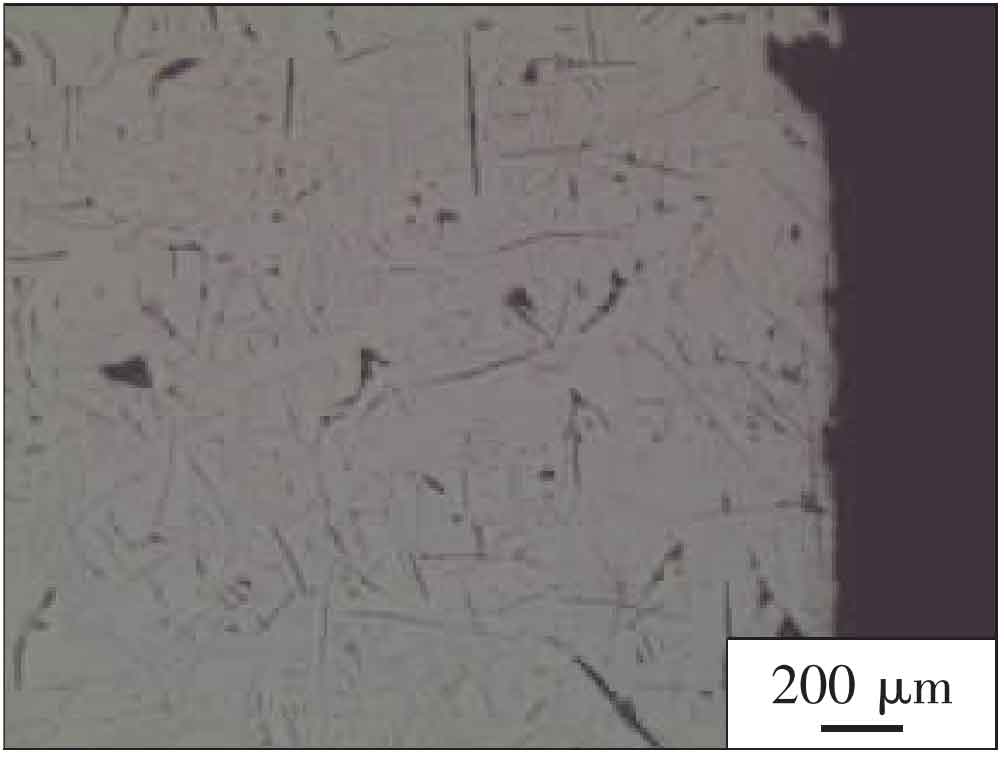

In the process of using a 30 piece QT600-3 gear, 2 pieces of gears were broken, as shown in Fig. 2 and Fig. 3.

According to the above pictures fed back by customers, it is preliminarily believed that shrinkage porosity or slag inclusion may exist, leading to the decrease of strength, so the breaking teeth are in use. Then, request the customer to send the broken gear back for hardness and metallographic test.

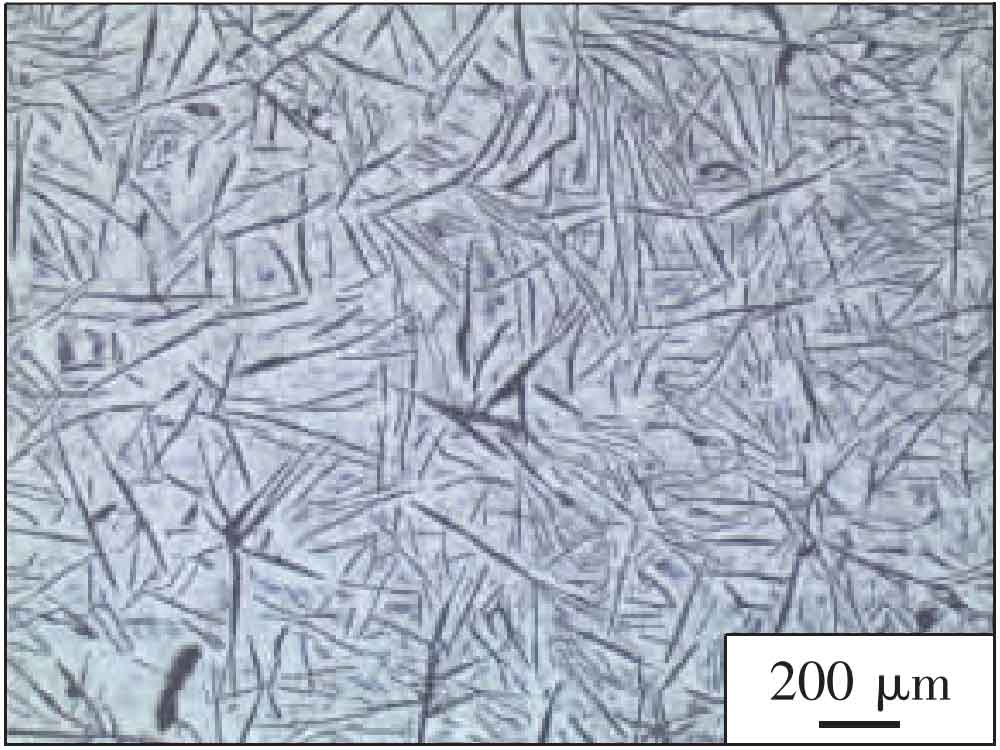

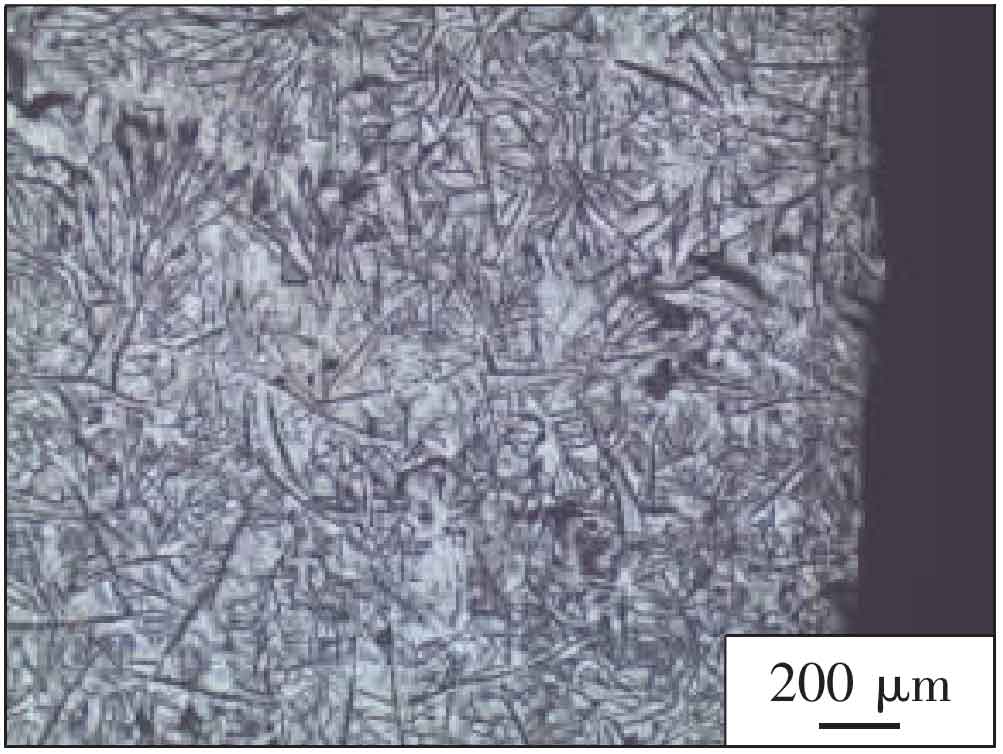

The hardness test is located on the flange opposite to the four vertical bars in Figure 1, with the hardness of 78 ~ 80 Hb. The metallographic test results show that the graphite is flake, and the volume fraction of pearlite in the matrix is 50%, as shown in Figure 4.

The results of chemical composition test of scrap parts show that: w (c) 3.71%, w (SI) 2.57%, w (MN) 0.51%, w (P) 0.029%, w (s) 0.026%, w (mg) 0.056%, w (RE) 0.020%, w (Cu) 0.41%. According to the inspection of sonic velocimeter, there are still 4 castings which are not spheroidized and the hardness is less than 100 Hb.