According to the location of the inner gate of the axle housing, the gating system can be divided into top pouring, middle pouring, step pouring and bottom pouring. The advantages and disadvantages of each scheme are analyzed.

Because the original casting process adopted bottom casting process, there are too many defects in the axle housing and it is difficult to guarantee the quality. According to the characteristics of the axle housing and the analysis of the gating system, combined with the parting surface of the axle housing, the middle pouring system is adopted.

In order to ensure that the liquid metal can fill the bridge shell, and obtain a clear outline and complete structure of the axle housing, the height from the highest point of the axle housing to the liquid level in the gate cup must be greater than or equal to the minimum value, that is, the necessary height of the sprue.

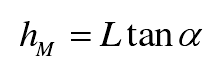

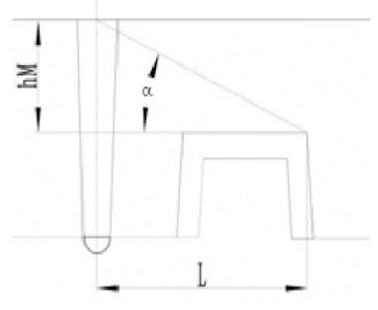

The formula of HM is as follows:

Where: HM is the minimum residual head height (mm);

L-the process of molten metal, i.e. the horizontal distance from the highest point of the bridge shell to the center line of the sprue (mm);

α – pressure angle.

When calculating the minimum residual head height, HM > L Tan α should be satisfied;

In the formula, the value of pressure angle is: α is 10 degrees;

The specific parameters of liquid metal flow are as follows:

Introduction position of gating system: l = 320mm;

The values of L and α are substituted into the formula: ltan α = 56mm,

Then the sprue height is not less than 56mm + 190mm = 246mm.