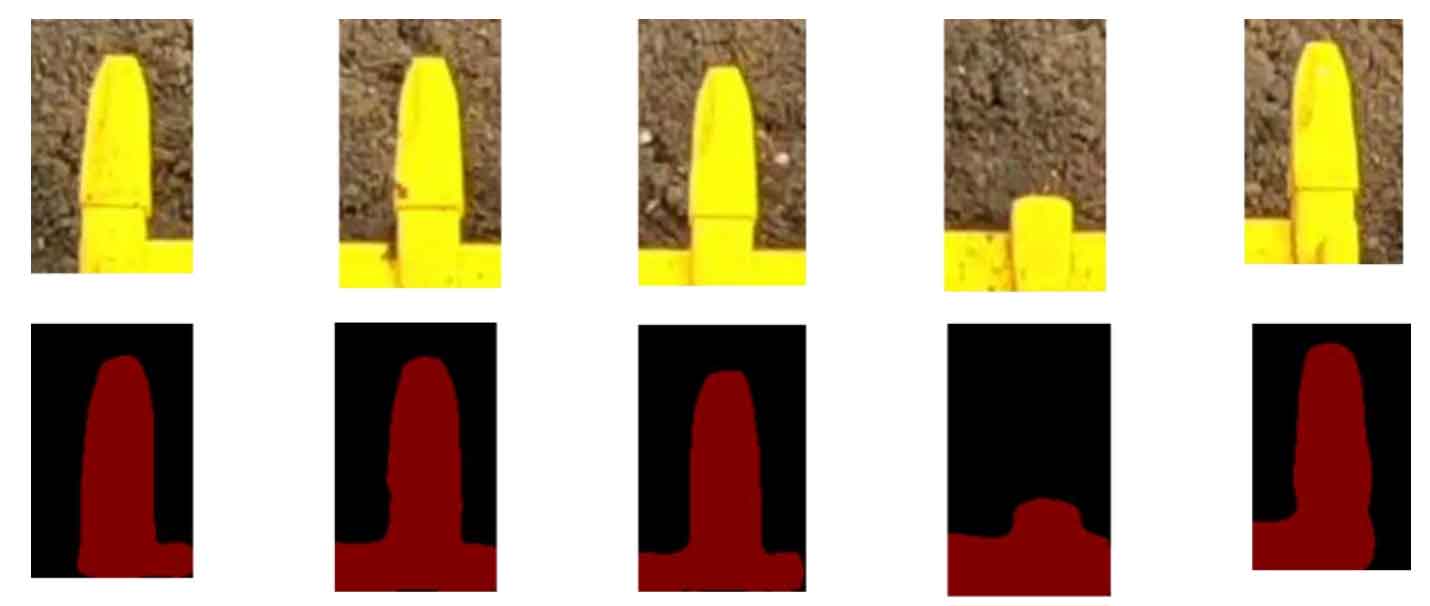

Because the image segmentation method based on deep learning can segment the better bucket tooth contour of excavator, the length of bucket tooth of excavator can be obtained by simple image processing method. The method can be used to preprocess to obtain the set of contour points.

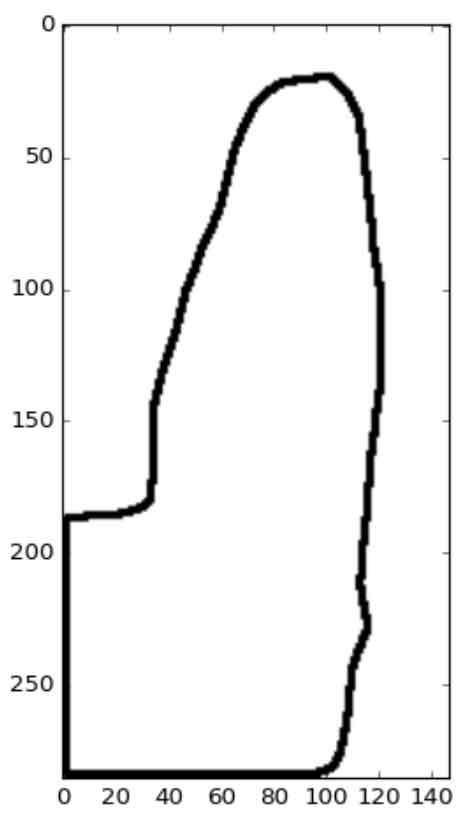

According to the characteristics of the bucket tooth contour of the excavator in the image, we scan the image line by line, that is, the contour points at the same height recorded in the contour image. In this way, the position of the tooth tip will be easier to find. For the bucket tooth contour of the excavator as shown in Figure 1, the tooth tip area is the part with the smallest pixel height value. It can be seen from the observation that there will be a large number of contour points at the same height in the area of the bucket tooth base of the excavator. The contour points at the bottom of the contour image are excluded. According to this characteristic, the base height of the bucket tooth of the excavator can be found, so as to obtain the pixel length of the bucket tooth of the excavator. The same is true for the faulty bucket teeth of the excavator. Record the minimum value of the pixel height of the contour and exclude the bottom contour points. The pixel length of the faulty bucket teeth of the excavator can be obtained by eliminating a large number of contour points at the same height. By comparing the pixel length of other bucket teeth of the excavator in the image, the wear degree of the bucket teeth of the excavator can be obtained. The definition of wear degree is as follows:

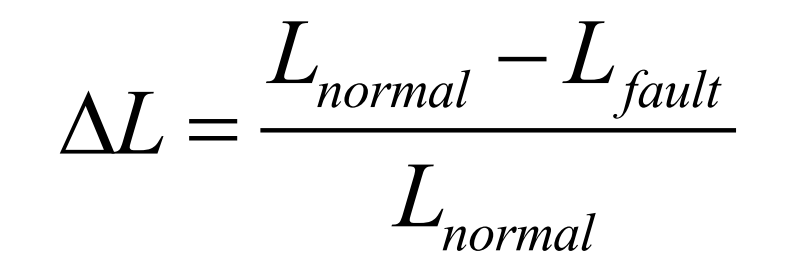

Where lfault is the pixel length measured by the faulty bucket teeth of the excavator, and lnormal is the average pixel length of other bucket teeth on the same bucket, Δ L represents the degree of wear.

We calculate the bucket tooth length of the excavator bucket teeth in Figure 2, compare the bucket tooth length of the excavator calibrated manually, and calculate the wear degree according to the formula.

| Bucket tooth number | Bucket tooth 0 | Bucket tooth 1 | Bucket tooth 2 | Bucket tooth 3 | Bucket tooth 4 | Wear degree |

| Marker length | 105 | 106 | 104 | 22 | 100 | 0.788 |

| Calculation length | 104 | 105 | 103 | 21 | 102 | 0.797 |

When the image segmentation result of excavator bucket teeth is more accurate, the length of excavator bucket teeth calculated by the algorithm designed in this section is close to the length of excavator bucket teeth calibrated manually. Since the algorithm designed in this section is based on pure image, the determination of wear degree is a preliminary determination, which aims to give the operator a more intuitive result, and the quality of the determination result depends on the performance of image segmentation.