Flywheel is one of the important parts of engine. When the output torque of the engine is greater than the effective resistance torque, the crankshaft will accelerate, otherwise it will decelerate, resulting in the fluctuation of crankshaft speed. Engine speed fluctuation will produce a series of adverse consequences. After installing the flywheel, when the crankshaft speed increases, the kinetic energy of the cast flywheel increases and the energy is stored; When the crankshaft speed decreases, the kinetic energy of the cast flywheel decreases and the energy is released to stabilize the crankshaft speed. Although the shape and structure of flywheel casting are simple, there are often shrinkage cavity and porosity casting defects, which affect the balance of Flywheel Casting.

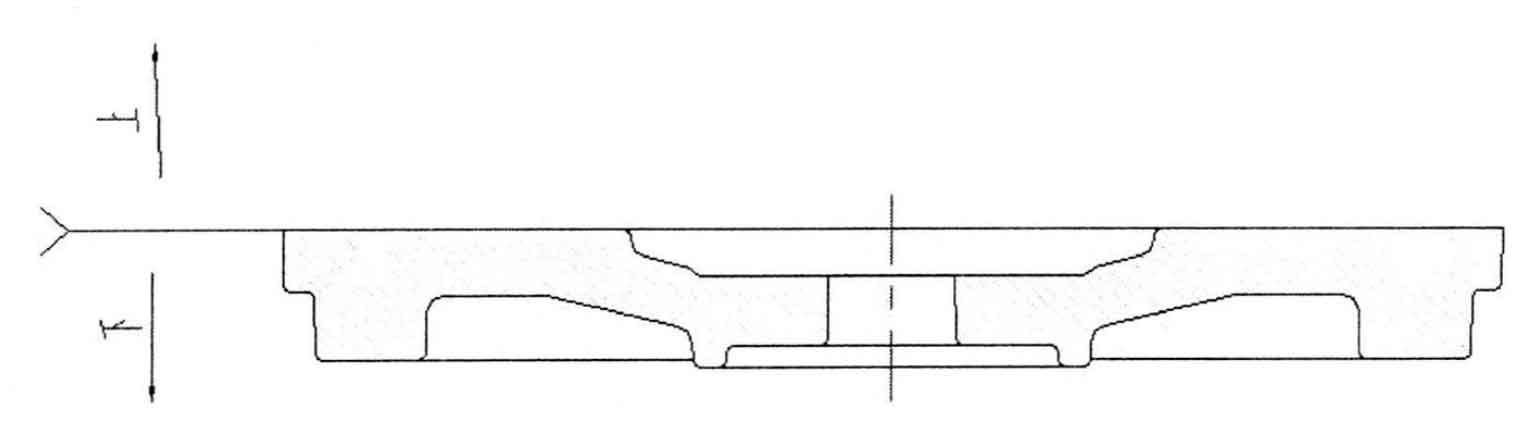

Figure 1 is the three-dimensional solid diagram of Flywheel Casting in the experiment, and the selection of parting surface is shown in Figure 2. The flywheel casting material is qt600.3, and the initial pouring temperature is 1380 ° C ~ 1420 ° C. The pouring time is 10s. The experiment will analyze the design of gating system and its influence on the quality of Flywheel Casting.