Scheme I

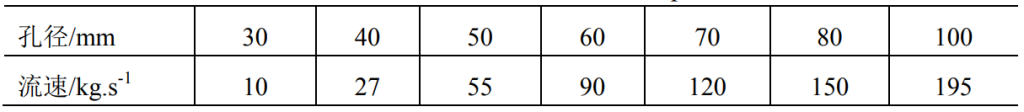

The casting mud pump body adopts single bag and single hole pouring, and the diameter of the injection hole is Φ 100mm,Aco=78.5cm2。 It can be seen from table 1 that the average flow rate of liquid metal during sand casting of mud pump body is 195kg / s.

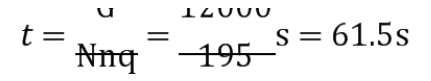

Sand casting pouring time of mud pump body t:

Where: G – casting weight (kg); N – number of ladle; N – number of injection holes in a single ladle; q: Average flow velocity of molten metal (kg / s).

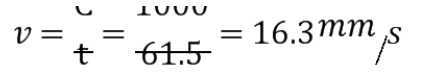

The rising speed of liquid metal in the mold can be used ν Check whether the sand casting pouring time of the mud pump body calculated by the formula is appropriate. The calculation formula is as follows:

Where:

V – rising speed of molten metal in the mold (mm / s);

C – height of casting (mm);

T – sand casting pouring time of mud pump body (s).

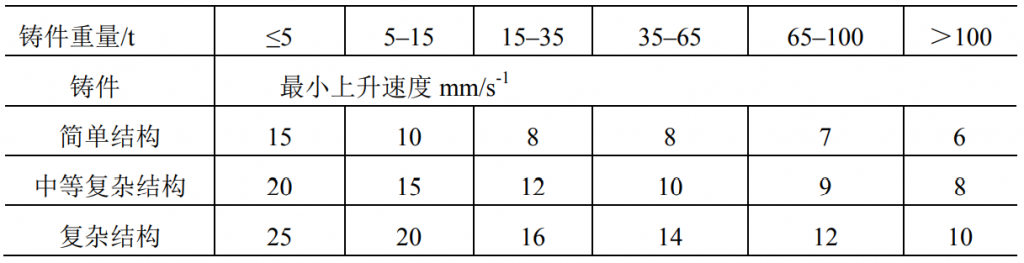

The value of V shall be greater than the corresponding value in Table 2, and the rising speed shall not exceed 30mm / s. The calculated rising speed of liquid metal is located in this interval, so it can be seen that the sand casting pouring time of mud pump body is appropriate.

Cross sectional area of each sprue of sand casting gating system for mud pump body:

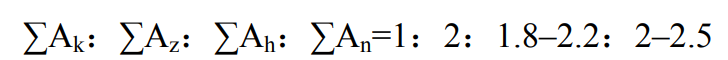

The sand casting gating system of the mud pump body selected for the casting is an open stepped gating system. The proportional relationship of the sectional area of each sprue can be calculated with reference to the proportional relationship of the formula:

Where: Σ AK – flow control cross-sectional area; Σ AZ – Total sectional area of sprue; Σ ah – total cross-sectional area of bottom runner; Σ an – total cross-sectional area of bottom ingate.

The cross-sectional area of the ladle is taken as the flow control cross-sectional area Σ AK. The pouring hole diameter of the ladle selected for the sand casting pouring system of the mud pump body is 100mm. According to the formula, the diameter of the straight sprue is designed as 140mm, the diameter of the transverse sprue is designed as 160mm, the diameter of the bottom inner sprue is designed as 100mm, and the total cross-sectional area of the upper inner sprue is 1-1.8 times that of the bottom inner sprue, Therefore, the diameter of the upper ingate is designed to be 140mm.

Scheme II

Ladle pouring is also used in process scheme 2. The pouring time and pouring speed of the cast mud pump body have been calculated according to the weight and structural characteristics of the mud pump body, and the appropriate ladle has been selected according to the sand casting pouring speed of the mud pump body. According to the formula, the relationship between the dimensions of each sprue of the sand casting gating system of the mud pump body is known. The diameter of the straight sprue is designed as 140mm, the diameter of the transverse sprue is designed as 160mm, and the diameter of the inner sprue is designed as 120mm.