The coupling design parameters in sand mold casting process parameters, such as casting temperature, holding time, cooling time, surface treatment, etc., are designed based on independent parameters, upstream customer demand input and enterprise casting process. The coupling design parameters are coupled with auxiliary material carbon source such as inoculant, smelting energy carbon source For example, the casting temperature is directly related to the consumption of thermocouples and the amount of gas produced by the thermal decomposition of adhesive, and the amount of inoculant increases or decreases with the change of casting temperature.

1.Carbon emission of materials based on coupling process parameters of sand casting

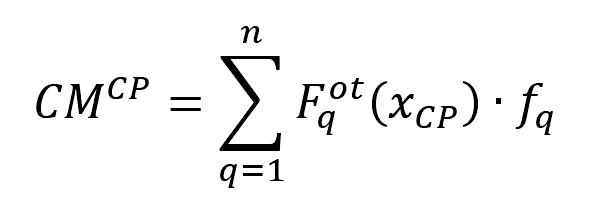

The material carbon source based on the coupling process parameters of sand casting includes smelting cooling water, thermocouple, antirust oil, inoculant and other auxiliary materials. The carbon emission is as follows:

2.Energy carbon emission based on sand casting coupling process parameters

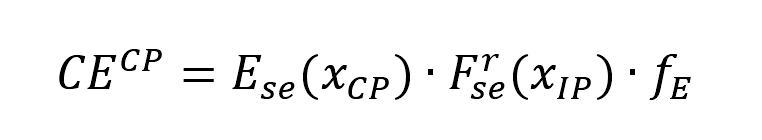

The energy carbon source based on the coupling process parameters of sand casting is concentrated on the smelting energy. The carbon emission of smelting energy consumption in the process of sand casting is calculated as follows:

3.Unexpected carbon emission based on coupling process parameters of sand casting

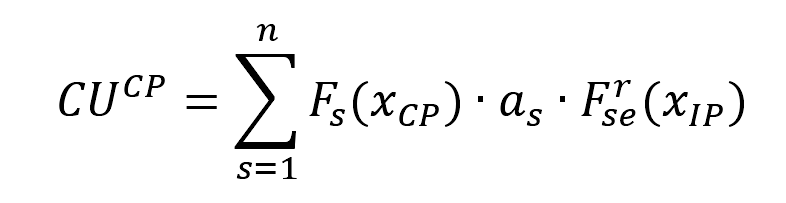

The unexpected carbon source based on the coupling process parameters of sand casting includes the carbon emission caused by the chemical change of materials such as slag forming agent in the smelting process, which is calculated as follows.