1. Basic information of steel castings

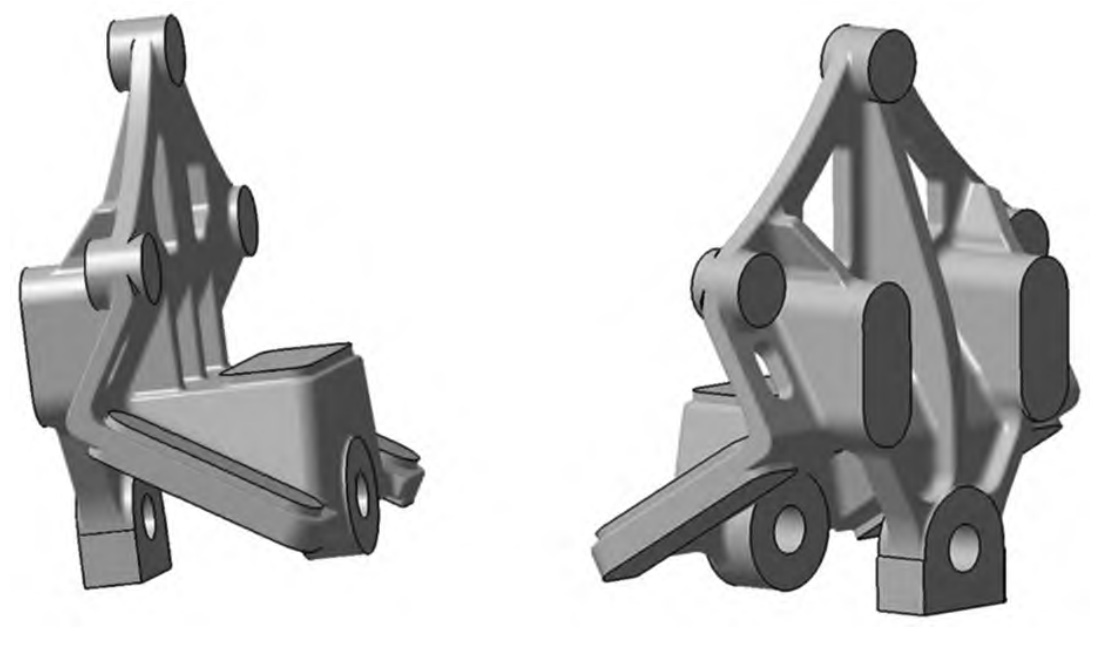

Support type steel castings, material: ZG310-570, unit weight: 12.8kg, structural characteristics: support structure, with many dispersed hot spots, difficult to shrink. The structure of the support steel castings is shown in Figure 1. The support type steel castings belong to a multi hot joint structure, and the casting process adopts a coated sand shell mold. The placement of the feeding riser and cold iron is often limited, and cannot be set according to conventional methods. It needs to be comprehensively considered and combined for use.

2. Casting process design

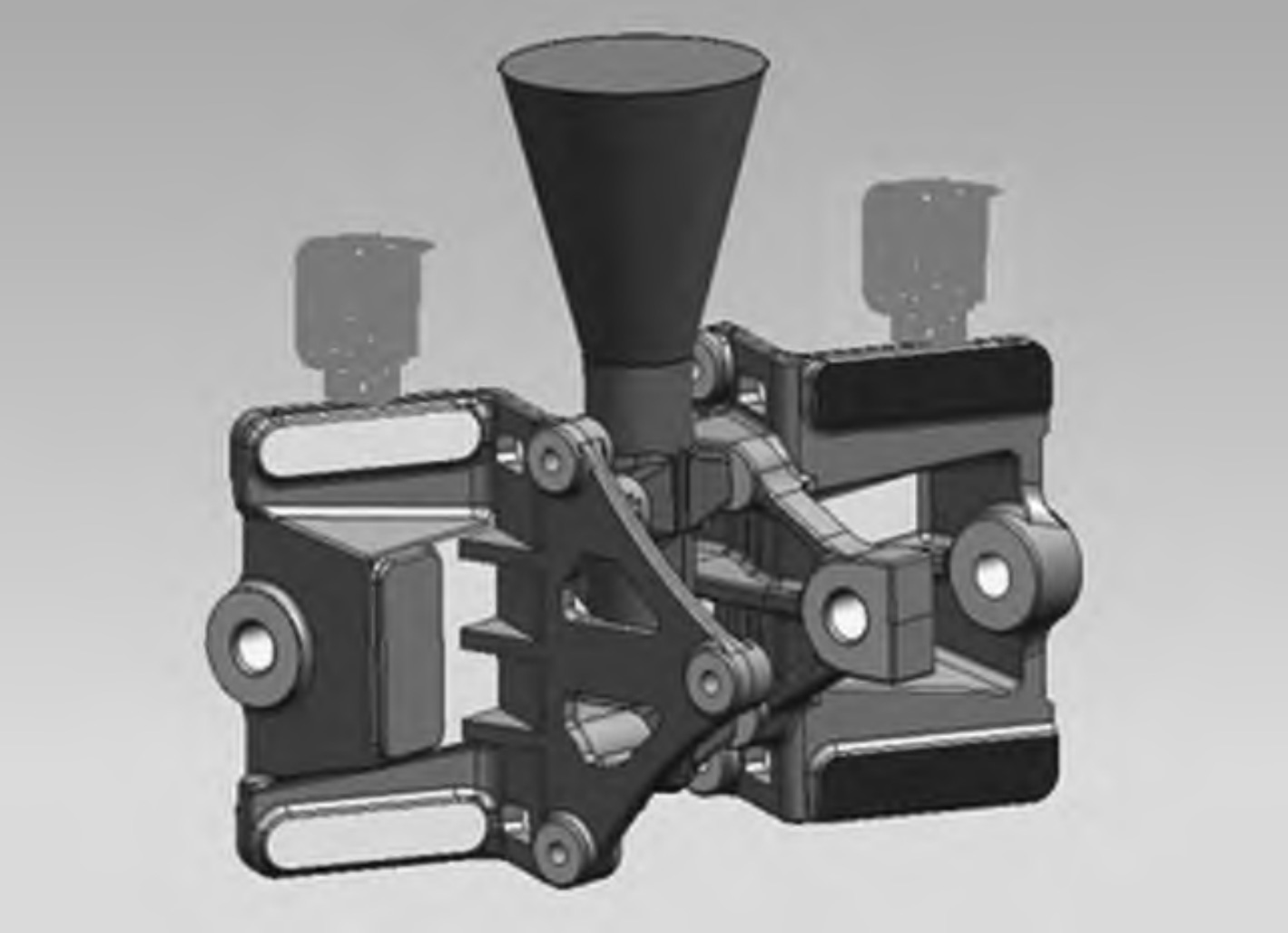

The support steel castings are produced using a coated sand shell mold, and the casting process is designed using vertical pouring. Due to the light weight of the castings, they are made into a group of two pieces, which are poured from two thick bosses and supplemented by vertical pouring channels; Cast holes on 4 bosses to reduce shrinkage tendency; Place a feeding riser in the thick part of the upper strip; Place an external cold iron on the thick part of the lower strip to eliminate shrinkage and looseness. The three-dimensional diagram of the casting process design for bracket steel castings is shown in Figure 2.

3. Cutting inspection

After pouring the support steel casting, cutting and dissection were conducted. From the cutting results, it can be seen that although the steel casting adopts process measures, there are still multiple internal shrinkage cavities and porosity. The photos of shrinkage holes and porosity defects in the bracket steel casting after dissection are shown in Figure 3.