Fig. 1 and 2 fracture of anchor claw in drop test, which is visually characterized by brittle fracture. The main causes are that the casting is placed in an unreasonable position during heat treatment, the heat treatment temperature does not meet the requirements, or the holding time is not enough or the heating is uneven, so that the as cast structure can not be completely eliminated, and there is residual casting internal stress.

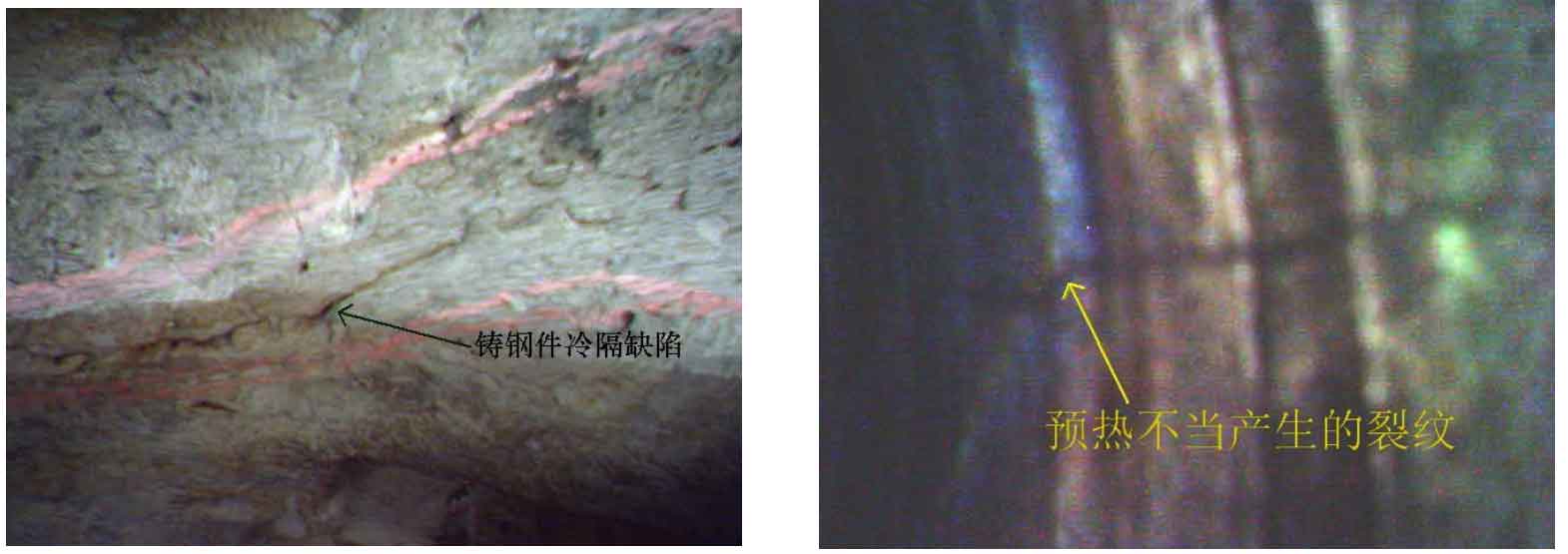

Fig. 3 the cold lap on the bottom of the casting plane is visually characterized by a “crack” like gap, but the gap has rounded edges. The main reason is that when the molten steel is punching, due to the low cavity temperature or pouring temperature, the molten steel flowing in front cools quickly, and the solid shell is blocked at the confluence of the two liquid flow heads.

Fig. 4 the visual characteristics of cracks caused by improper preheating belong to cold cracks. It is caused by uneven preheating and improper preheating method during welding repair of casting defects.