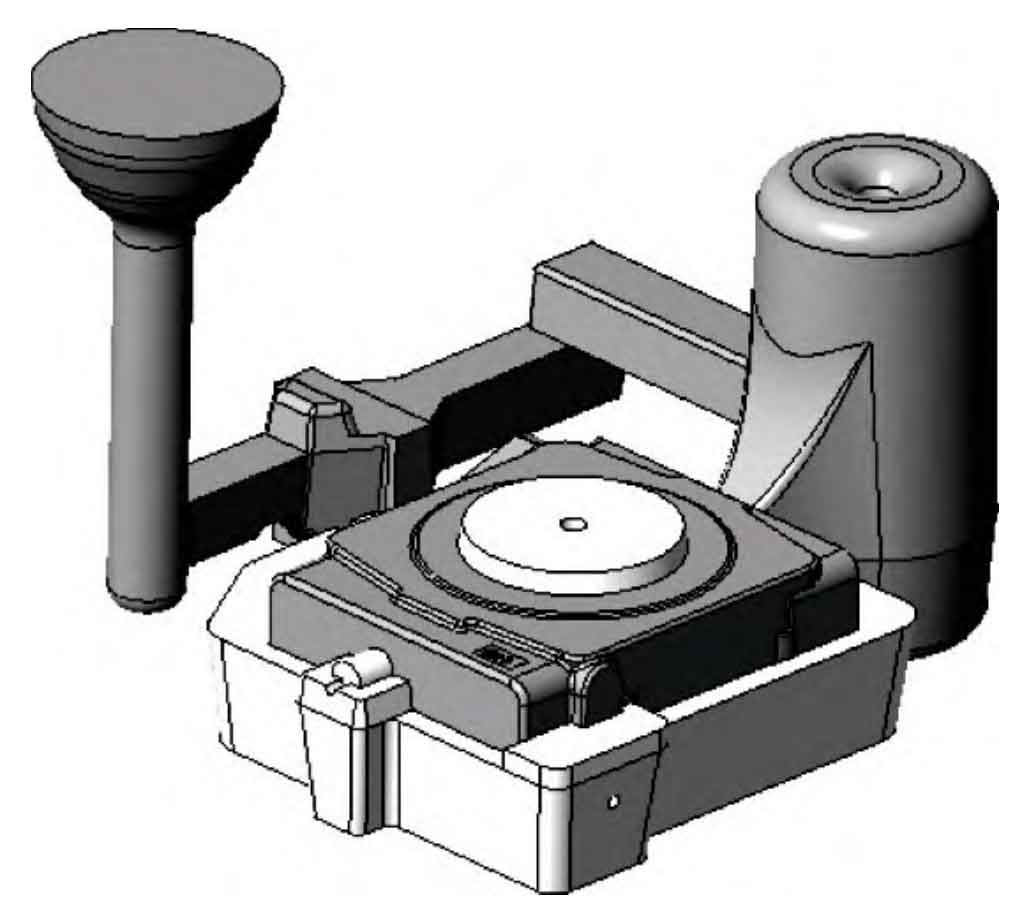

1) Gating system design

According to the above parting surface and sand core of ductile iron castings, the gating system, except for the vertical runner, the transverse runner and the inner runner are distributed above and below the parting surface. The inner runner is connected with the riser of ductile iron castings. During pouring, the molten iron finally enters the mold cavity of ductile iron castings through the side riser. The gating system adopts a step-by-step open gating system. The sectional area ratio of each component of the runner is: F vertical: F resistance: F horizontal: F internal=1.2 ∶ 1 ∶ 1.2 ∶ 1.5, A foam ceramic filter is arranged in front of the flow blocking section. The filter can play a role in combing the flow and filtering the scum or particles in the molten iron into the mold cavity.

2) Design of feeding riser

In view of the endogenous paste solidification mode of nodular cast iron, there are cases in the casting industry to achieve balanced solidification without riser, but the control requirements for the metallurgical quality and nucleating ability of molten iron and nucleating time are strict. In view of the practical experience in the past development of nodular cast iron castings, the pump cover developed this time has poor heat dissipation conditions due to the small internal oil channel of nodular cast iron castings, and the oil channel sand core is completely wrapped in molten iron during solidification, The actual solidification modulus of nodular iron castings is larger than that calculated by the mathematical model. Secondly, the rigidity of the clay sand mold is not enough. In order to ensure the stable production in batches, the sequential solidification method is finally selected for feeding, and the ratio between the nodular iron castings and the riser modulus is controlled to be 1 ∶ 1.5. In order to prevent the sand core from being deformed, broken or washed out due to excessive baking when molten iron enters the mold cavity of ductile iron castings, the riser neck is staggered and the sand core is set between two oil channels. At the same time, the hot spot area of the pump cover ductile iron castings is mainly concentrated in the center of the ductile iron castings, and the final solidification area must be introduced into the riser during the solidification of molten iron, That is to say, the feeding channel from the hot spot area of nodular cast iron to the feeding riser must be unblocked at all times. The riser is set at the side of ductile iron casting, taking into account the mold filling and feeding of molten iron, and the oil channel sand core is staggered at the same time, as close as possible to the central hot spot to achieve sequential solidification. The casting process plan is shown in the figure.