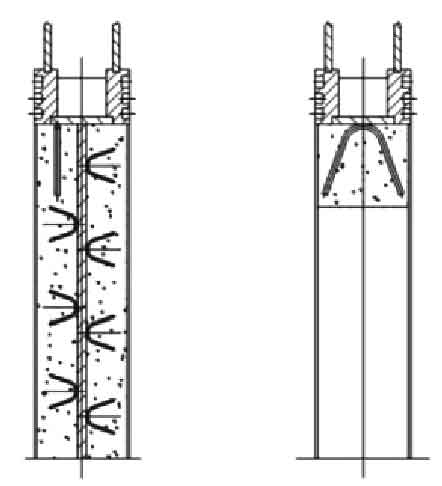

The inside of valve plate also needs pouring refractory layer, and the minimum width of valve plate is determined according to the thickness of refractory layer. In order to avoid the heat transfer effect of the blind hole panel leading to the sealing performance reduction of the sealing ring, it is necessary to pour high alumina cement refractory castable on the whole 2 sides of the blind hole panel. On the side of through-hole plate, only high alumina cement refractory castable is poured on the inner wall of cylinder, and the thickness is the same as that of valve body. The V-shaped ribs welded on the inner wall of the valve plate are evenly distributed according to the thickness of the refractory layer (as shown in the figure).

The valve plate sealing seat adopts three sealing rings, the outer ring is silicone rubber sealing ring, and the inner two are flexible expanded graphite rings. Flexible expanded graphite is resistant to high temperature, corrosion and low thermal conductivity, so that the outer ring silicone rubber seal is not eroded by high temperature, which effectively ensures the overall sealing performance of the valve.