This paper presents the casting process design and production practice of a rod-shaped wear-resistant cast iron casting. The shell molding method is employed to shorten the production cycle, and spherical risers are used to solve the feeding problem and improve the reliability of the casting process. Alcohol-based coating is applied to the sand mold to prevent the occurrence of subcutaneous porosity defects and enhance the internal quality of the product.

- Introduction

A rod-shaped casting with a contour size of φ40 mm × 326 mm is produced by the company, and its material is high-chromium cast iron Cr20. This cast iron is a typical wear-resistant white iron, characterized by high hardness and a structure in which a strong and tough metal matrix supports high-strength carbides. However, due to its low thermal conductivity, poor plasticity, and large shrinkage, it has a high tendency for hot and cold cracking, resulting in poor casting performance. The original process used precision casting, but it had a high scrap rate (about 20%), a long production cycle, and high consumption of raw materials, leading to low process yield and production efficiency. Therefore, the film coated sand shell casting process is adopted in this design. - Casting Process Design

2.1 Casting Process

The linear shrinkage rate of the rod-shaped casting is designed to be 2% considering its material, high-chromium cast iron Cr20. According to the structure and size of the product, the modulus of the part that requires feeding is calculated to be M_part = 1/4 × 4.5 cm = 1.125 cm using the modulus method. Thus, the modulus of the riser is calculated as M_riser = (1.1 – 1.2) × M_part = 1.15 × 1.125 cm = 1.24 cm. Considering the structure and practicality, a spherical riser (with the smallest volume under the same specific surface area) is applied in the process design. Based on the principle of the spherical riser feeding the hot spot of the casting, the design is carried out, and the diameter of the spherical riser D is calculated to be 7.44 cm. Therefore, the size of the spherical riser is determined to be SR = 1/2 × 6 × M_riser = 3.75 cm. The spherical riser is designed at the tail of the rod-shaped casting, as shown in Figure 2, to facilitate the bottom-up directional solidification of the molten iron during the solidification process.

| Parameter | Value |

|---|---|

| Contour size | φ40 mm × 326 mm |

| Material | High-chromium cast iron Cr20 |

| Linear shrinkage rate | 2% |

| Modulus of the part requiring feeding (M_part) | 1.125 cm |

| Modulus of the riser (M_riser) | 1.24 cm |

| Diameter of the spherical riser (D) | 7.44 cm |

| Size of the spherical riser (SR) | 3.75 cm |

2.2 Casting Method

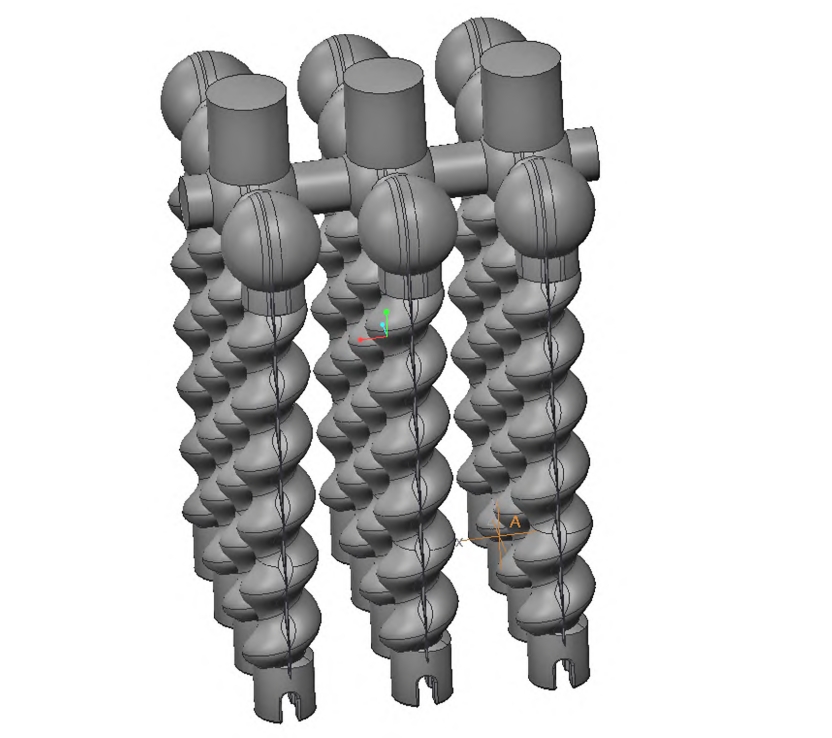

The sand mold (core) is produced using the film coated sand shell casting process. It is made using a metal mold on a 40 kg hot core shooter, with each mold consisting of two left and right pieces. The sand mold is designed to produce 4 castings per mold, and the sand core is designed to be shared by 4 castings to form the inner cavity structure of the head of the rod-shaped casting. A special serial tooling is used for the assembly and molding of the sand mold (core). Each casting is equipped with a spherical riser, and the rod-shaped castings in each mold are connected by a φ40 mm cross runner. The sand molds are connected by a φ40 mm serial runner. In the current process scheme, 6 sand molds (cores) are combined into one pouring group, and one pouring group casts 48 rod-shaped castings. A pouring cup is set for the guidance of the molten iron, as shown in Figure 4.

| Parameter | Value |

|---|---|

| Sand mold production method | film coated sand shell casting process |

| Hot core shooter capacity | 40 kg |

| Number of pieces in each mold | 2 (left and right) |

| Castings per mold | 4 |

| Sand core sharing | 4 castings share 1 sand core |

| Connection between castings | φ40 mm cross runner |

| Connection between sand molds | φ40 mm serial runner |

| Number of sand molds in one pouring group | 6 |

| Castings per pouring group | 48 |

| Pouring cup setting | 1 for molten iron guidance |

2.3 Melting Process

The molten iron is melted using a medium-frequency induction furnace. The chemical composition of the molten iron is controlled as follows: w(C) 2.8 – 3.0%, w(Si) ≤ 0.6%, w(Mn) 0.5 – 0.8%, w(P) ≤ 0.02%, w(S) ≤ 0.04%, and w(Cr) 20.0 – 21.0%. The tapping temperature of the molten iron is controlled at 1500 °C ± 10 °C. The molten iron is poured into a special pouring ladle, and the pouring is carried out using a crane ladle method (the original process used a carrying ladle for pouring, with one ladle of iron divided into 3 pourings for 3 mold shells). The pouring process follows a “slow – fast – slow” rhythm, and the pouring gate should be punched 1 – 2 times immediately after filling. After the molten iron solidifies for more than 8 hours, the shot blasting cleaning operation can be carried out.

| Parameter | Value |

|---|---|

| Melting furnace type | Medium-frequency induction furnace |

| Chemical composition control of molten iron | w(C) 2.8 – 3.0%, w(Si) ≤ 0.6%, w(Mn) 0.5 – 0.8%, w(P) ≤ 0.02%, w(S) ≤ 0.04%, w(Cr) 20.0 – 21.0% |

| Tapping temperature | 1500 °C ± 10 °C |

| Pouring method | Crane ladle |

| Pouring rhythm | “slow – fast – slow” |

| Punching times after filling | 1 – 2 times |

| Time after solidification for shot blasting | More than 8 hours |

2.4 Process Simulation

To further verify the reliability of the process, the ProCAST virtual simulation software is used to conduct numerical simulation calculations on the process of the rod-shaped casting. The simulation results show that no shrinkage cavities are found inside the casting, as shown in Figure 5. This indicates that the process has certain operability and provides favorable support for the subsequent actual production.

| Parameter | Value |

|---|---|

| Simulation software | ProCAST |

| Simulation result | No shrinkage cavities found inside the casting |

- Process Test and Verification

Through the process design of the rod-shaped casting and the fabrication of the hot core box metal mold, the film coated sand (core) is made according to the process requirements after the completion of the hot core box. The molten iron is melted using a medium-frequency induction furnace, and the actual tapping temperature is 1509 °C. The casting is poured in 4 times using a 500 kg pouring ladle for one furnace (4 pouring groups for one furnace), and the measured pouring speeds are 30 s, 28 s, 29 s, and 28 s. In the later stage, the poured castings are cut and cleaned, and no porosity or shrinkage defects are found at the root of the spherical riser and the tail of the rod-shaped casting, as shown in Figure 6. To further verify the reliability of the process, the rod-shaped casting is dissected using wire cutting, and the internal structure of the casting is found to be dense without any porosity or other casting defects, as shown in Figure 7. Subsequently, the castings and the gating system are weighed, and the casting process yield of this product is calculated to be 70.5%, which is 5% higher than that of the original precision casting process.

| Parameter | Value |

|---|---|

| Actual tapping temperature | 1509 °C |

| Pouring ladle capacity | 500 kg |

| Pouring times for one furnace | 4 (4 pouring groups for one furnace) |

| Measured pouring speeds | 30 s, 28 s, 29 s, 28 s |

| Casting defects at the root of the spherical riser and the tail of the casting | None found |

| Internal structure of the casting | Dense without porosity or other defects |

| Casting process yield | 70.5% (5% higher than the original process) |

According to the order situation, the trial-produced rod-shaped castings are sent out for machining to further verify the reliability of the process. During the machining process, it is found that the machining allowance of the rough casting is reasonable, and no “black skin” or other defects are found, indicating that the size of the rod-shaped casting is qualified. However, it is found that some castings have surface porosity defects to varying degrees after machining, as shown in Figure 8. According to statistics, the proportion of this porosity defect is about 90%. Due to the particularity of the high-chromium cast iron, there is no repair measure for the product, resulting in the batch scrapping of the product.

| Parameter | Value |

|---|---|

| Machining allowance of the rough casting | Reasonable |

| Presence of “black skin” or other defects | None found |

| Proportion of surface porosity defects | About 90% |

Further analysis reveals that the porosity defect should be subcutaneous porosity. The reason is that the binder used in film coated sand contains hexamethylenetetramine, which decomposes into NH3 and CN when heated. These two gases have low chemical binding energy and are easily decomposed into atomic states. When 卷入 into the molten metal, they are prone to form pores during the solidification of the casting. In addition, film coated sand itself has a large gas evolution rate, resulting in the inability to effectively remove the gas inside the mold during the pouring process, thereby causing a certain degree of subcutaneous porosity defects in the casting.

To effectively solve the problem of subcutaneous porosity in the rod-shaped casting, targeted experimental improvements are taken. Specifically, before assembling the sand mold (core), the sand mold (core) is immersed in an overall alcohol-based coating and ignited and dried in time to pre-decompose and remove NH3 and CN and fully remove the residual moisture in film coated sand mold. In addition, the inner surface coating is beneficial to prevent the occurrence of porosity defects. The machined rod-shaped castings produced after the improvement show that the porosity problem has been effectively solved.

| Parameter | Value |

|---|---|

| Cause of porosity defect | Subcutaneous porosity due to hexamethylenetetramine in the binder and large gas evolution rate of film coated sand |

| Improvement measure | Immersion in alcohol-based coating and timely ignition and drying |

| Effect of improvement | Porosity problem effectively solved |

- Conclusion

- The application of spherical risers effectively solves the feeding problem of rod-shaped castings, facilitates the improvement of the casting process yield, and reduces the consumption of raw materials.

- The immersion coating of film coated sand mold cavity or surface with alcohol-based graphite coating can prevent the occurrence of subcutaneous porosity defects in the casting while improving the surface finish of the casting.

In summary, the casting process design and production practice of the rod-shaped wear-resistant cast iron casting have achieved good results. The use of film coated sand shell casting process,spherical risers, and alcohol-based coating has improved the quality and production efficiency of the casting, providing a valuable reference for the production of similar castings in the future.