Abstract:

The comprehensive analysis and optimization of the casting process for a nodular cast iron tool stand. The original process, which utilized risers for feeding shrinkages, resulted in slight shrinkage porosities. Through various scheme analyses and numerical simulations, a riser-free casting process was adopted, leading to qualified castings with simplified molding and increased yield. This paper details the casting structure, process design, numerical simulation, quality analysis, and practical conclusions.

1. Introduction

Nodular cast iron, known for its excellent mechanical properties and castability, is widely used in the manufacturing of machine tool stands. However, the production of large and complex nodular cast iron tool stands often faces challenges such as shrinkage porosities and low casting yield. This paper focuses on the casting process optimization of a nodular cast iron tool stand, aiming to improve casting quality and reduce production costs.

2. Casting Structure and Material

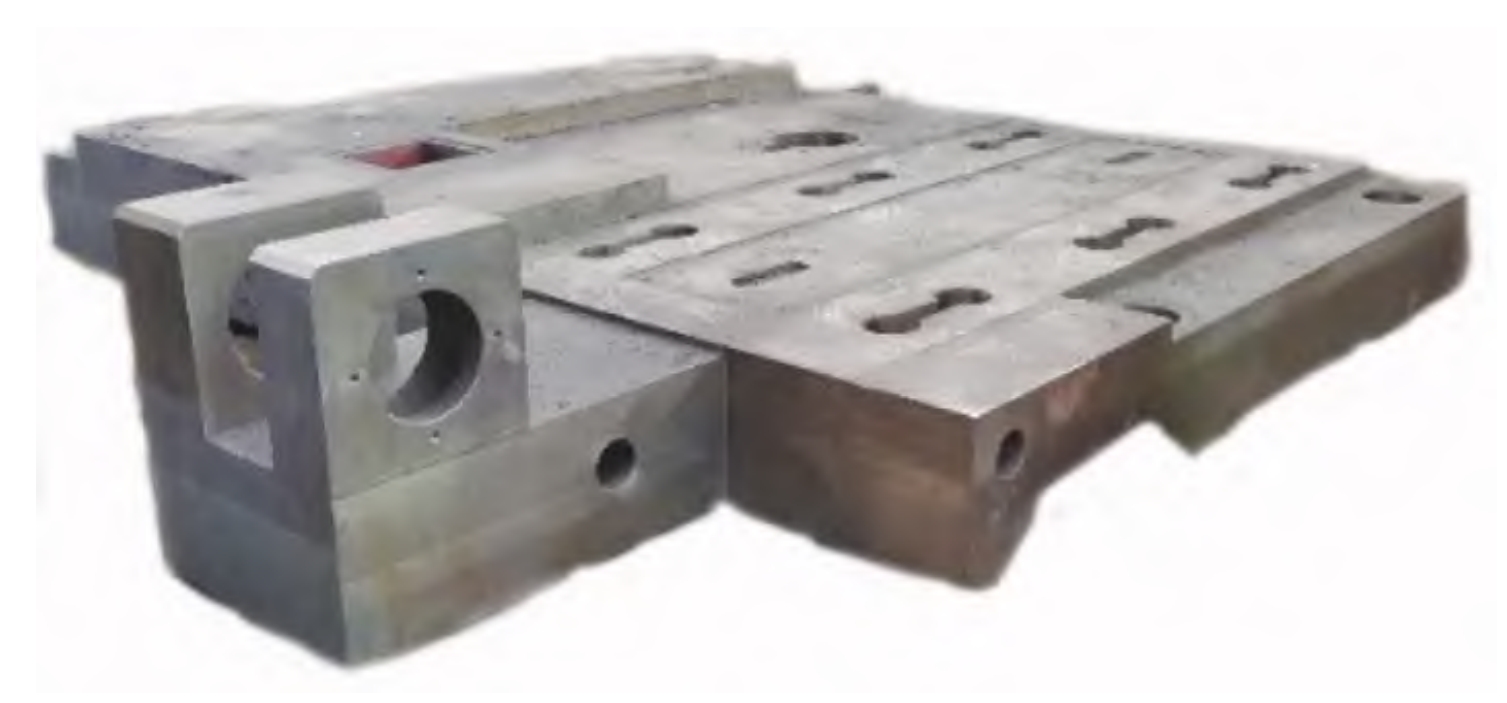

The tool stand is made of QT400-18 nodular cast iron, with dimensions of 2,230 mm × 1,750 mm × 550 mm and a weight of approximately 2,483 kg. The casting features a complex internal cavity structure with varying wall thicknesses, ranging from 20 mm to 80 mm. The top of the casting includes a thick support frame with a Φ70 mm hole, which requires high microstructural and mechanical properties.

Table 1: Casting Dimensions and Material

| Casting Material | QT400-18 Nodular Cast Iron |

|---|---|

| Dimensions (mm) | 2,230 × 1,750 × 550 |

| Weight (kg) | 2,483 |

| Wall Thickness (mm) | 20 – 80 |

3. Casting Process Design

3.1. Molding and Pouring Parameters

The casting is produced in small batches, with a quality level of H2 according to EN 12890 and a precision grade of DIN ISO 8062-CT12. The working holes on the casting are machined after casting. The surface roughness of the main working surfaces should reach Ra12.5 μm through cutting. The casting requires high internal and external quality, with no defects such as sand inclusion or shrinkage porosities.

The casting uses furan resin-bonded self-hardening sand for molding, with scrap steel and carburizing agent as the main raw materials. The composition of the original molten iron is controlled as follows: 3.6%-4.0% C, 1.3%-1.6% Si, Mn ≤ 0.5%, S ≤ 0.03%, P ≤ 0.04%. After nodularization, the composition is adjusted to: 3.5%-3.9% C, 2.2%-2.5% Si, Mn ≤ 0.45%, S ≤ 0.02%, P ≤ 0.04%, with residual Mg ≤ 0.05%. The tapping temperature is approximately 1,450°C, and the pouring temperature ranges from 1,310°C to 1,330°C.

Table 2: Molding and Pouring Parameters

| Parameter | Value |

|---|---|

| Molding Material | Furan Resin-Bonded Self-Hardening Sand |

| Raw Materials | Scrap Steel + Carburizing Agent |

| Original Molten Iron Composition | C: 3.6%-4.0%, Si: 1.3%-1.6%, Mn ≤ 0.5%, S ≤ 0.03%, P ≤ 0.04% |

| Nodularized Molten Iron Composition | C: 3.5%-3.9%, Si: 2.2%-2.5%, Mn ≤ 0.45%, S ≤ 0.02%, P ≤ 0.04%, Mg ≤ 0.05% |

| Tapping Temperature (°C) | 1,450 |

| Pouring Temperature (°C) | 1,310 – 1,330 |

3.2. Gating System Design

Due to the large size, varying wall thicknesses, and complex internal structure of the nodular cast iron casting, an open step gating system with multiple ingates was adopted to ensure balanced filling and solidification. The ingate cross-section is designed as a flat rectangle to reduce flow resistance and improve casting quality.

4. Numerical Simulation and Quality Analysis

4.1. Shrinkage Defect Prediction

Using AnyCasting software, the temperature field during solidification of the casting was simulated. The results showed that the final solidification area was near the thick support frame with the large hole at the top, indicating a potential for shrinkage porosities.

4.2. Riser-Based Feeding Attempt and Issues

Initially, two risers were placed above the support frame to feed the shrinkages. However, shrinkage porosities appeared at the riser roots, and simulations showed that the risers solidified before the casting, indicating ineffective feeding.

5. Optimization of the Casting Process

5.1. Riser-Free Casting Process

Based on the numerical simulations and practical issues, a riser-free casting process was adopted. The original risers were replaced with wedge-shaped vent holes, and the ingate thicknesses were reduced. External or internal chills were placed near the holes to improve the microstructure and performance.

5.2. Numerical Simulation Results

Simulations showed that the ingates and vent holes solidified before the casting, ensuring effective feeding and reducing shrinkage porosities. The casting quality was further improved by using multiple ingates for balanced filling and a pouring temperature of approximately 1,320°C to reduce liquid shrinkage.

6. Practical Results and Conclusion

6.1. Casting Quality and Yield

Qualified castings were obtained using the optimized riser-free casting process. The use of high-strength resin sand molds, tight sand box clamping, thin ingate thicknesses, and appropriate chills significantly improved casting quality and yield.

6.2. Conclusion

- Ineffectiveness of Risers: Due to the nodular cast iron’s paste-like solidification characteristics, the use of risers was ineffective in preventing shrinkage porosities and reduced casting yield.

- Optimized Process: The adoption of high-strength resin sand molds, thin ingate thicknesses, wedge-shaped vent holes, and appropriate chills, along with a pouring temperature of 1,310°C to 1,330°C, enabled faster filling and balanced solidification, improving casting quality and reducing production costs.

- Riser-Free Casting: Both with and without casting out the bearing holes, qualified castings could be obtained using the riser-free casting process with external or internal chills.

- Machining Improvement: Not casting out the bearing holes facilitated molding and chill placement, and improved the quality of the machined holes.

Table 3: Summary of Casting Process Optimization

| Process Improvement | Description |

|---|---|

| Riser Removal | Replaced with wedge-shaped vent holes |

| Ingate Thickness Reduction | To ensure effective feeding |

| Chill Placement | Near the holes to improve microstructure |

| Pouring Temperature | 1,310°C – 1,330°C for balanced solidification |

| Casting Quality | Improved with riser-free process |

In conclusion, the adoption of a riser-free casting process with appropriate modifications in gating system design, chill placement, and pouring parameters significantly improved the quality and yield of the nodular cast iron tool stand castings. This optimization not only reduced production costs but also simplified the molding process, making it more efficient and cost-effective.