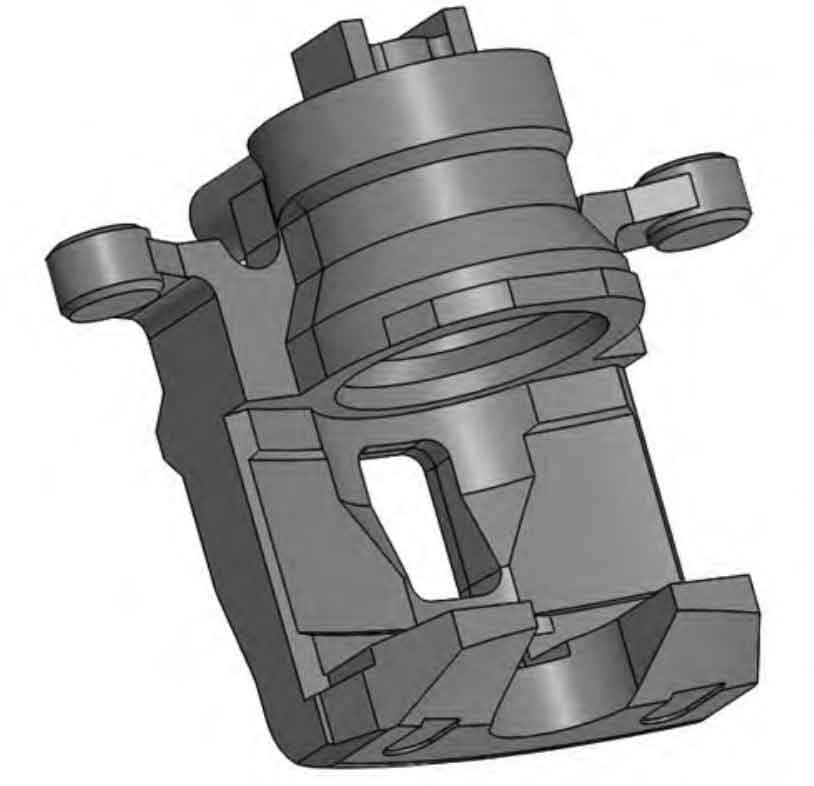

The structure and technical requirements of automobile brake caliper castings are described from the aspects of process layout, riser design, gating system design, etc. The casting process of nodular cast iron castings is changed from the traditional vertical placement of the cylinder barrel to the horizontal placement of the cylinder barrel, the original arrangement of four nodular cast iron castings is increased to six nodular cast iron castings, and the placement direction of the nodular cast iron castings is adjusted reasonably to improve the process yield and production efficiency. The casting process was simulated and analyzed by numerical simulation software to verify the feasibility of the casting process. Through the actual production verification, the metallographic structure, mechanical properties and surface quality of the nodular iron castings produced meet the technical requirements, and the total scrap rate of the nodular iron castings is controlled within 1.9%.

With the rapid development of the automobile industry, the demand for auto parts is higher and higher, and the output is higher and higher. According to the development experience of the company and the production of nodular iron castings for automobile calipers, the process layout method to improve the yield rate is proposed.

The automobile brake calipers are produced by the vertical parting boxless molding process. The traditional placement method of the nodular cast iron parts is the vertical placement of the cylinder barrel. Now, by using the horizontal placement method of the cylinder barrel, the original arrangement of four nodular cast iron parts is increased to six nodular cast iron parts, which improves the process yield and production efficiency, and the metallographic structure and mechanical properties of the nodular cast iron parts meet the technical requirements.