When the Volga car factory was built in toruyaqi, Russia in 1987, a piston ring branch factory was built in order to solve the matching problem of piston rings for 600000 cars per year. In order to improve the manufacturing technology level of nodular cast iron piston rings, a piston ring barrel casting production line, machining production line and all technical data were introduced from Japan RIKEN company at a cost of US $100000.

The piston ring branch has only three varieties. The first ring is nodular cast iron piston ring. A Japanese Guangyang sm-50v molding production line is adopted to produce concave positioning elliptical simplified nodular cast iron piston ring blanks. The other three full-automatic high-pressure molding lines (equivalent to Getz full-automatic molding line) are purchased from the Belarusian Institute of foundry and equipment science, which are used to produce alloy cast iron blanks for the second gas ring and the third oil ring.

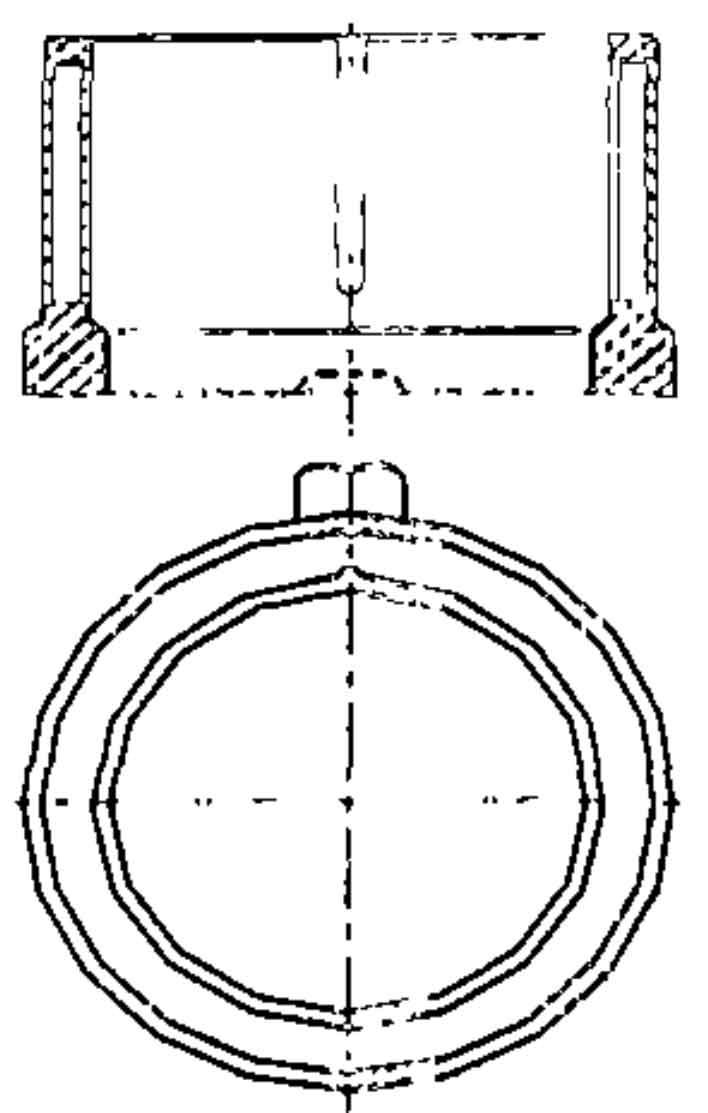

The blank of spheroidal graphite cast iron piston ring with elliptical cylinder is shown in the figure. Nine self-made automatic slicers are used to slice the blank of simplified nodular cast iron piston ring in Volga automobile factory, Russia. Compared with German Gertz and Japanese RIKEN, this equipment has simple design and high efficiency. It is an ideal equipment for blank slicing of cylinder nodular cast iron piston ring.