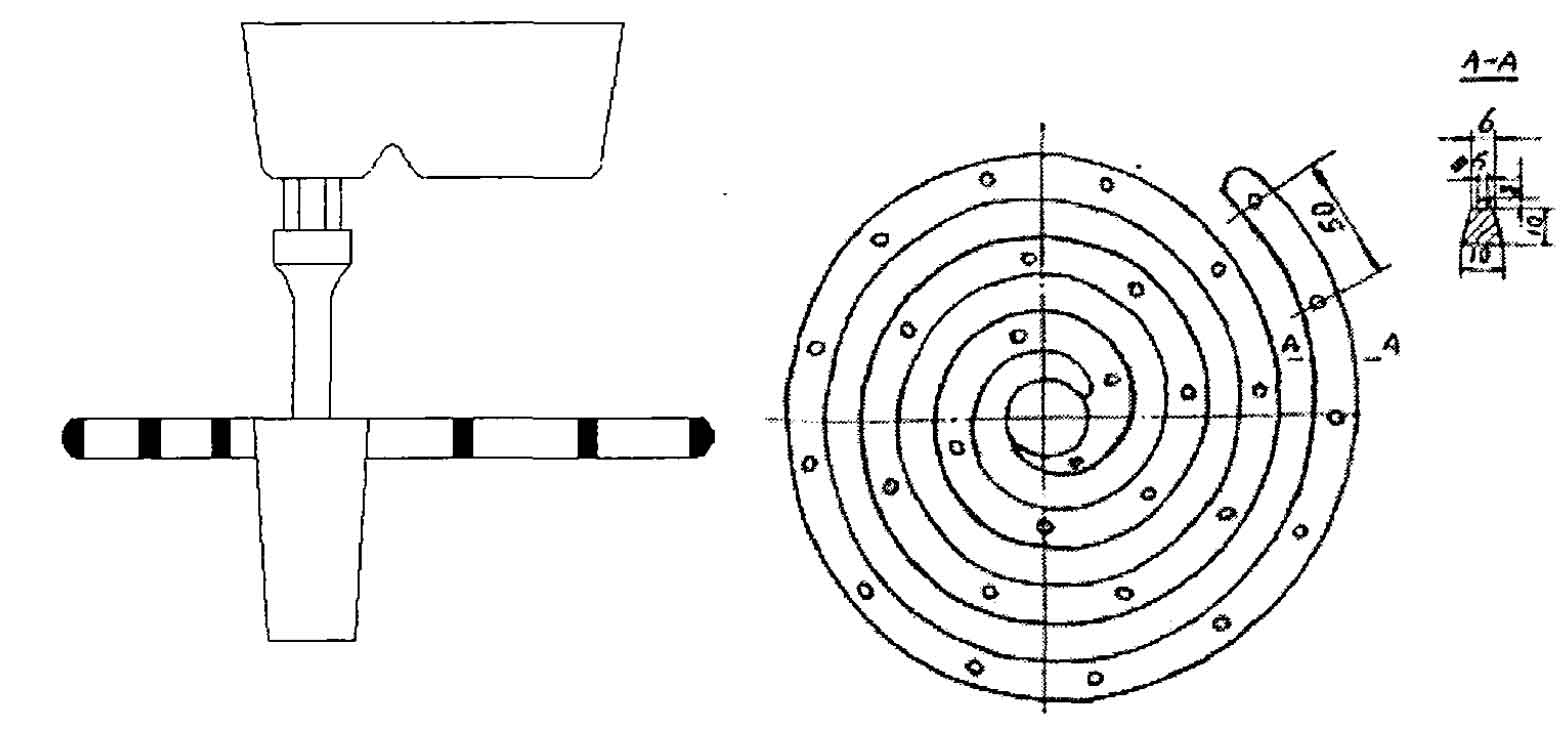

1.Liquidity test

As shown in Figure 1, the experimental fluidity test adopts the method of single helix wet sample. The size of the spiral sample mold is small, the molding is easy and sensitive, and the distance for liquid metal flow is long (e.g. 1.5m). However, due to the bending of liquid metal flow curve, the friction resistance loss along the way is large, so it is necessary to ensure that there is enough pressure head. The fluidity test should be reshaped every time. During the test, try to ensure that the pouring temperature is the same every time, and the gate cup is filled to ensure the same pressure and the accuracy of fluidity test.

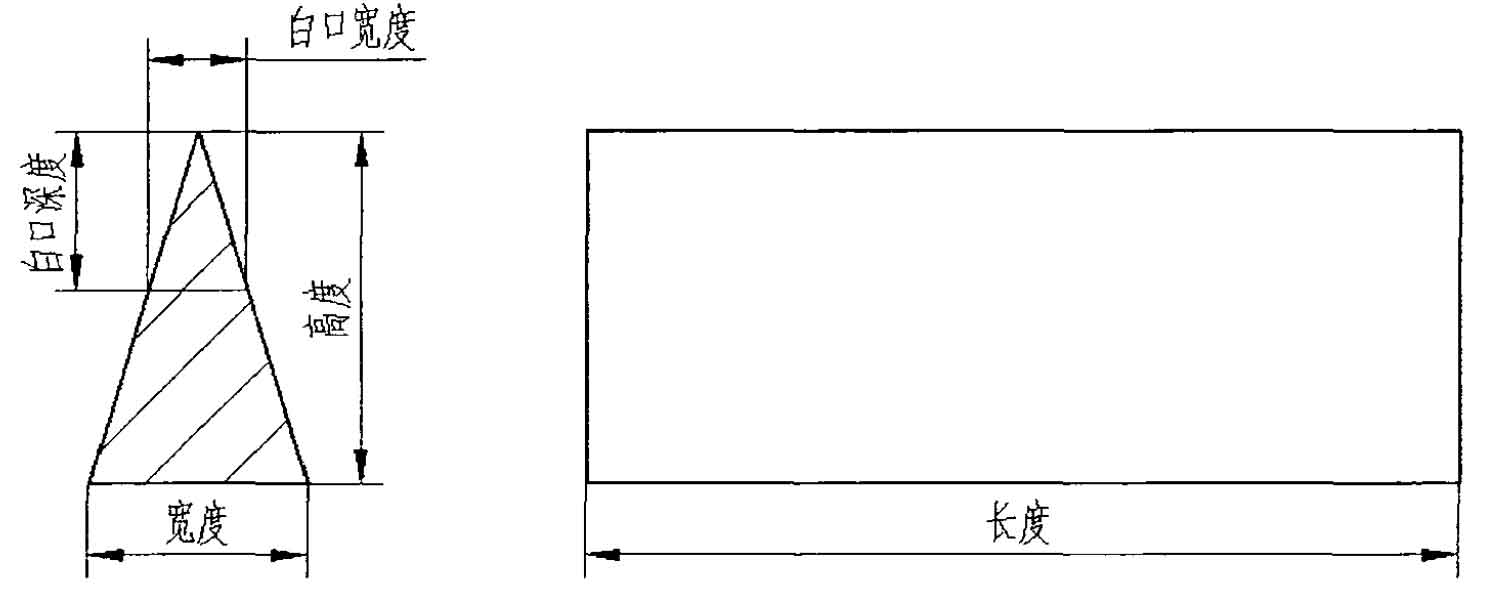

2.White mouth tendency

The white tendency of low carbon equivalent gray cast iron was tested by triangular sample method, and the pouring method was wet vertical pouring. After pouring and cooling, measure the white mouth width of the sample after smashing the sample. As shown in Figure 2, the basic dimensions of the triangular sample are 120mm long, 35mm wide and 35mm high. The dimensional accuracy shall be ensured during the modeling of triangular test block, and the pouring temperature shall be high enough during pouring. Otherwise, the number of white holes is not easy to measure due to insufficient pouring at the tip of the test block.

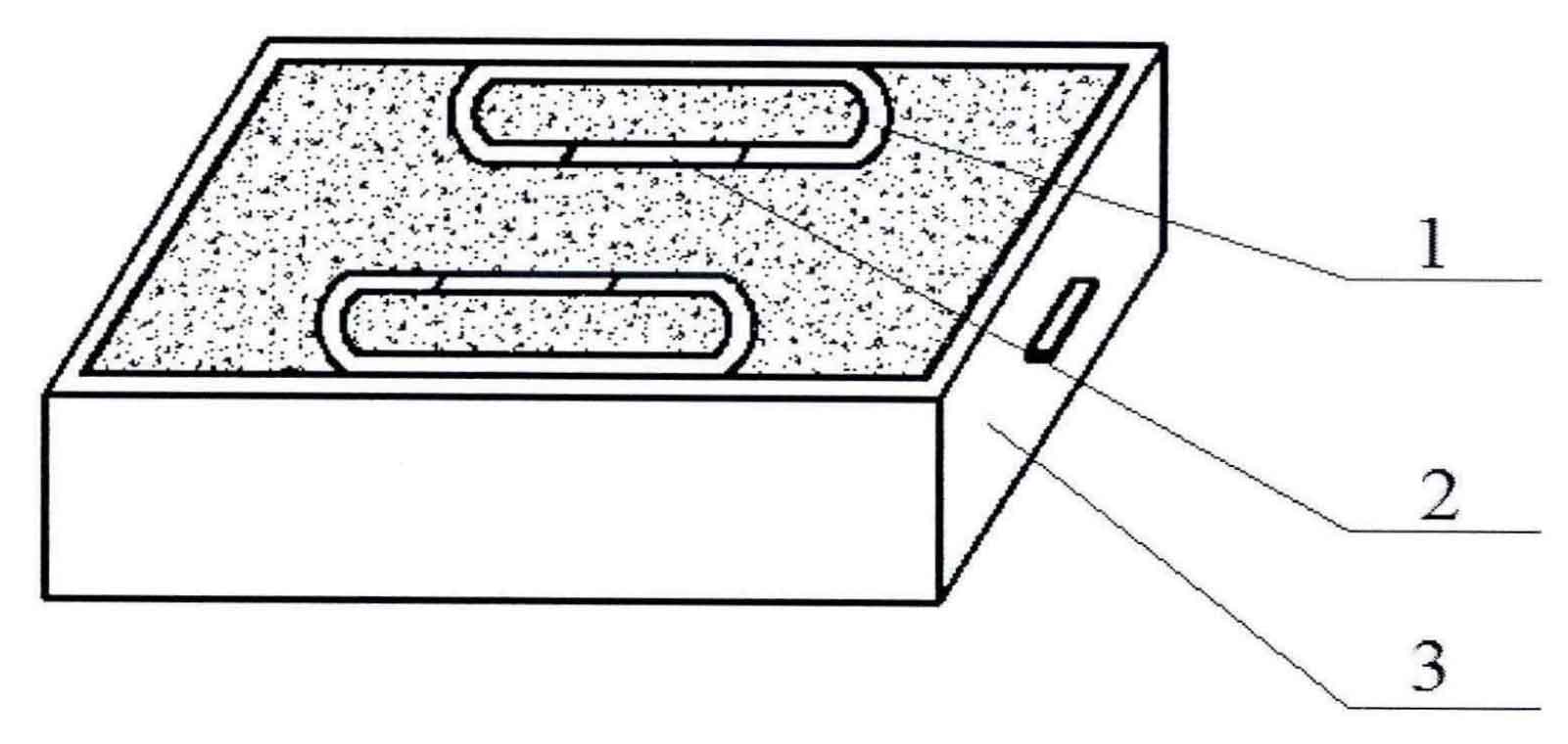

3.Linear shrinkage tendency

The shrinkage tendency of iron crucible sample was tested. Generally speaking, the linear shrinkage can be used as an expression of the solid shrinkage. The solid shrinkage is calculated from the beginning when the sample shows the solid property. The so-called solid property refers to the morphological transformation process from liquid to solid for some casting alloys that can crystallize, A property of primary dendrites that grow continuously until they are connected to each other and form a network skeleton. When the alloy is solidified and formed, at this time, with the decrease of sample temperature, the atomic spacing of the alloy decreases, and then the alloy outline size and solid volume are reduced, resulting in solid shrinkage.

The sand mold for testing the linear shrinkage of gray cast iron is shown in Figure 3.

After melting gray cast iron, pour it. After the sample is cooled, measure it with vernier caliper. The distance between the clamp iron L1 (mm), the length of the sample L2 (mm). The calculation formula of shrinkage is as follows:

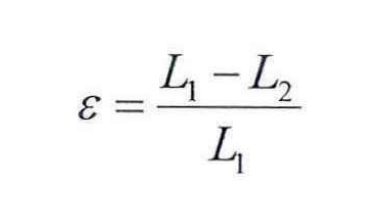

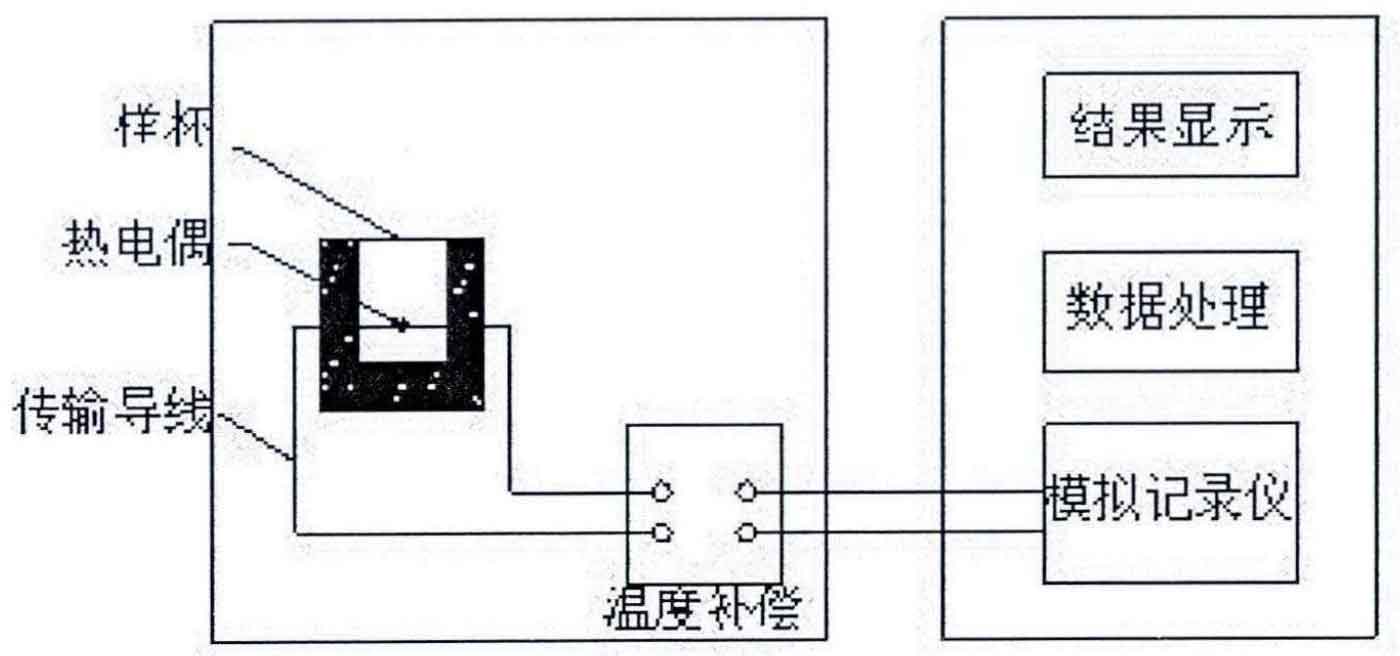

4.Thermal analysis test

The alloy thermal analyzer used in the experiment is multi lab Quik cup. During pouring, the molten iron modified with different amounts of rare earth alloy will be poured into the sample cup for analysis and test. According to the change of phase transformation temperature point temperature of gray cast iron, the influence of rare earth alloy modification on the crystallization process of low carbon equivalent gray cast iron is analyzed. As shown in Figure 4.