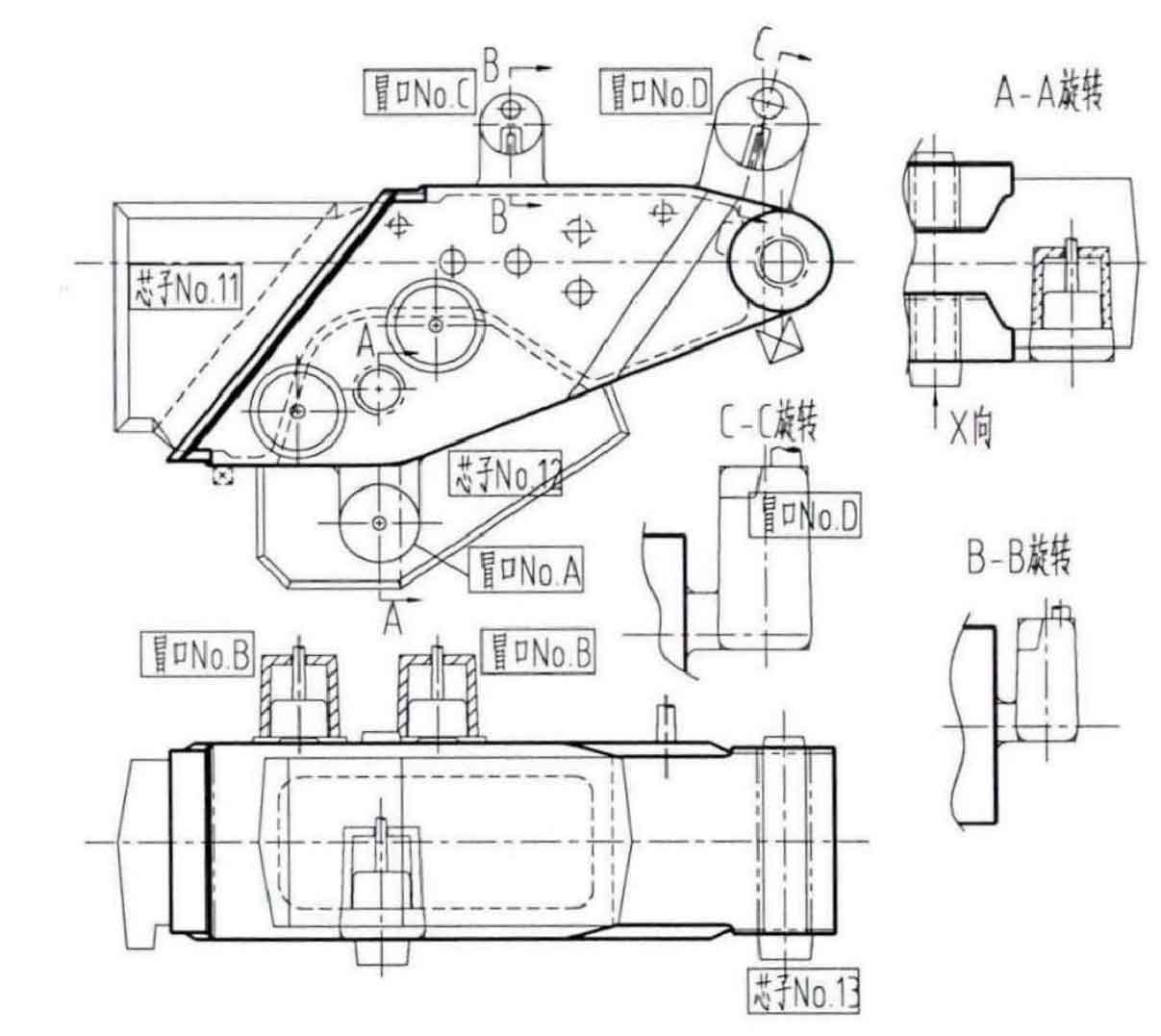

Draw the process drawing of sand casting according to the processing quantity and riser calculated before. Refer to attached Fig. 1 for the process diagram of sand casting.

The gating system of sand mold casting is the channel to introduce liquid metal into the mold cavity. The successful pouring process depends on the nature of the metal itself, the nature of the mold and the structure of the pouring system. The gating system of sand mold casting can be divided into four categories according to the section proportion of each unit, including closed, open, semi closed and closed open.

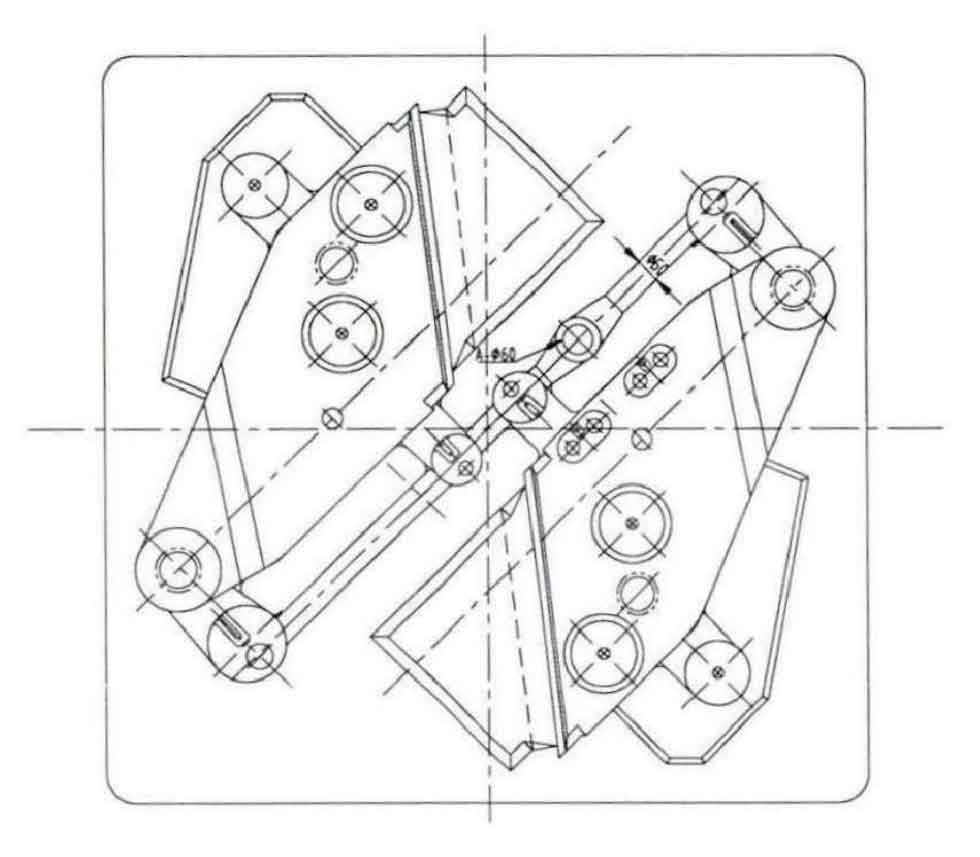

The closed pouring system is used, which is easy to fill the pouring system with liquid metal, has strong slag retaining capacity and less liquid metal consumption. According to the internal technical standards of the company, the closed gating system is selected, and the diameters of sprue and transverse sprue are respectively Φ 6 0 、 Φ 50. The runner is directly connected with the side riser, which is conducive to the stable pouring of liquid metal and the timely discharge of gas in resin sand. Draw the tooling drawing, and the sketch is shown in Figure 2.