As the diesel engine represented by compact and efficient has gradually become the mainstream of modern ship power selection, it requires that the wall thickness of diesel engine castings become thinner and thinner, more and more spatial curved curve structures, more and more complex shapes, and higher requirements for size and surface accuracy. As one of the key castings of diesel engine, the cylinder head is integrated with its oil cavity, water cavity, air cavity and other functional cavities, and its wall thickness is thin, and the dimensional accuracy requirements are increasingly high. In the casting process, there are many sand core cantilever phenomena, and the sand core support positioning is difficult. The traditional production method based on manual operation is affected by mold precision, core box locking degree, sand scraping surface height, core compactness and other factors, and the sand core deformation is large, and it is difficult to ensure the dimensional tolerance of castings. Aiming at the current casting requirements of key parts of marine diesel engine, the research on the casting process of high-precision cold core box of diesel engine cylinder head was carried out.

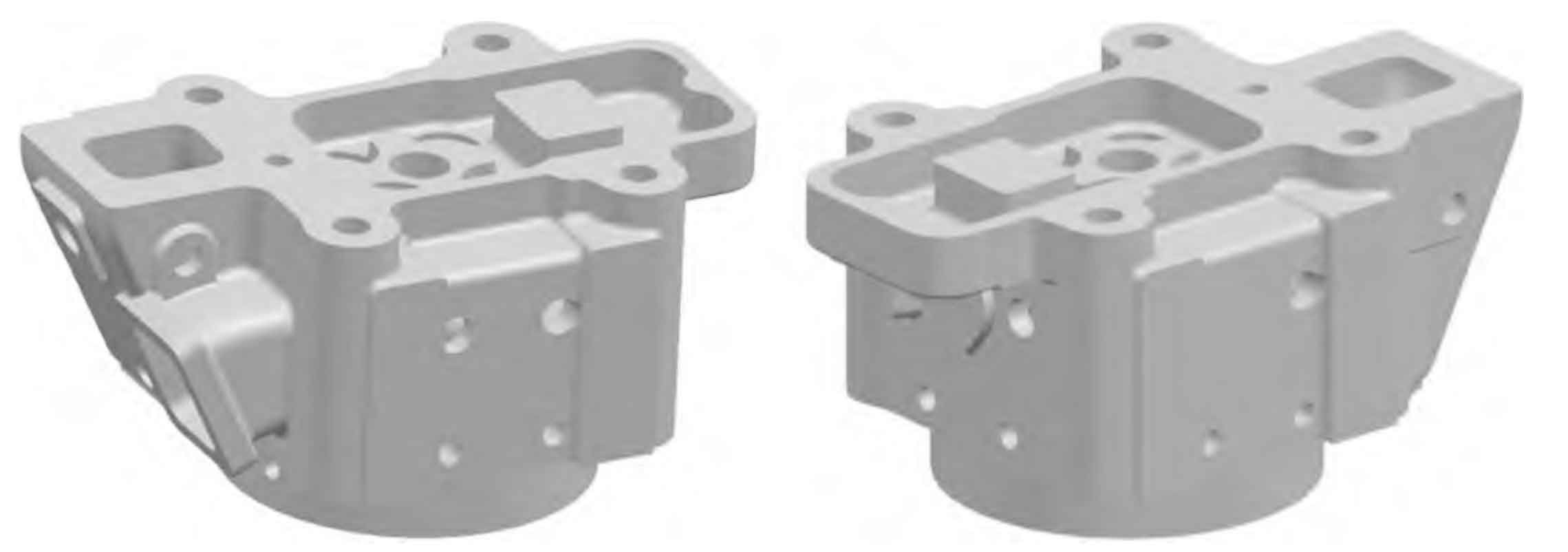

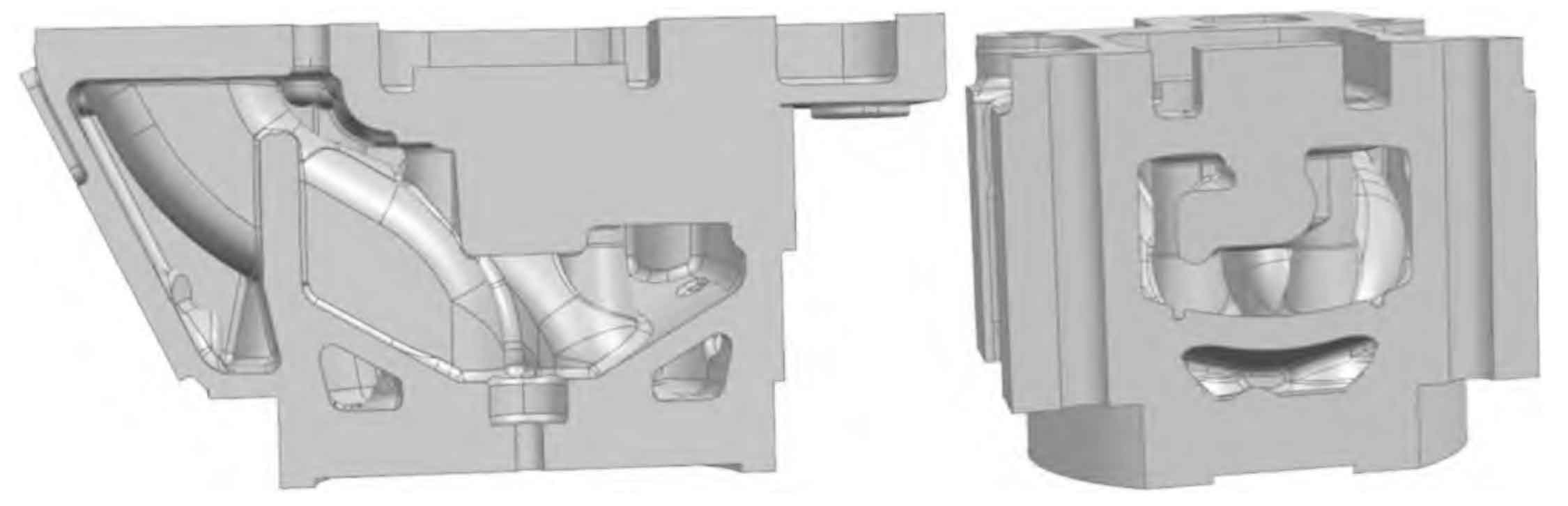

The maximum contour dimension of the cylinder head is 732 mm × 441 mm × 347 mm, gross weight 350 kg, cooling water chamber, air inlet, exhaust duct and through screw hole (4) are arranged inside. The main wall thickness dimensions are: the wall thickness of the upper plane is (30 mm+10 mm), the wall thickness around the inlet and exhaust duct is 12 mm, and the wall thickness of the combustion surface (bottom) is (45 mm+7 mm). The cooling water chamber of the cylinder head is composed of the lower water chamber and the upper water chamber. The exhaust duct is wrapped by a water chamber with a wall thickness of 12 mm. The upper part of the high pressure oil pipe is connected with the oil injection hole. The wall thickness is large and the hot spot is relatively large. See Fig. 1 and Fig. 2 for the appearance and internal section of the casting. The sand core is made by high-precision cold-box core shooter, the casting material is QT400-15, and it is melted by 3t medium-frequency induction furnace.