With the gradual increase of environmental protection, low energy consumption, low emissions and low pollution have become the goals of innovative design of mechanical products. In order to improve the efficiency of the engine and reduce emissions, the design of the cylinder block tends to be integrated, making its structure more complex, and the requirements for the casting process are also higher and higher. The new generation cylinder block integrates the structure of water channel, oil airway and gear chamber, and has higher requirements for core assembly and sand core exhaust in the process of casting production. In the trial production of the new generation cylinder block, the company designed it according to the traditional cylinder block process in the early stage. During the trial production, 100% of the upper surface of the cylinder block produced pores, which could not meet the processing needs.

(1) The sand core structure of the new generation cylinder block is complex. Reducing the gas output of the sand core and ensuring the smooth exhaust of the mold (core) are effective means to reduce the pore defects in production. In particular, the matching part of the mold core should be well sealed to prevent the metal liquid from drilling into and blocking the exhaust channel.

(2) The cavity thin wall is placed at a higher position, the open riser is designed when the casting allows, the gating system and exhaust system are optimized, and the rapid pouring can reduce the porosity rejection rate of the cylinder block.

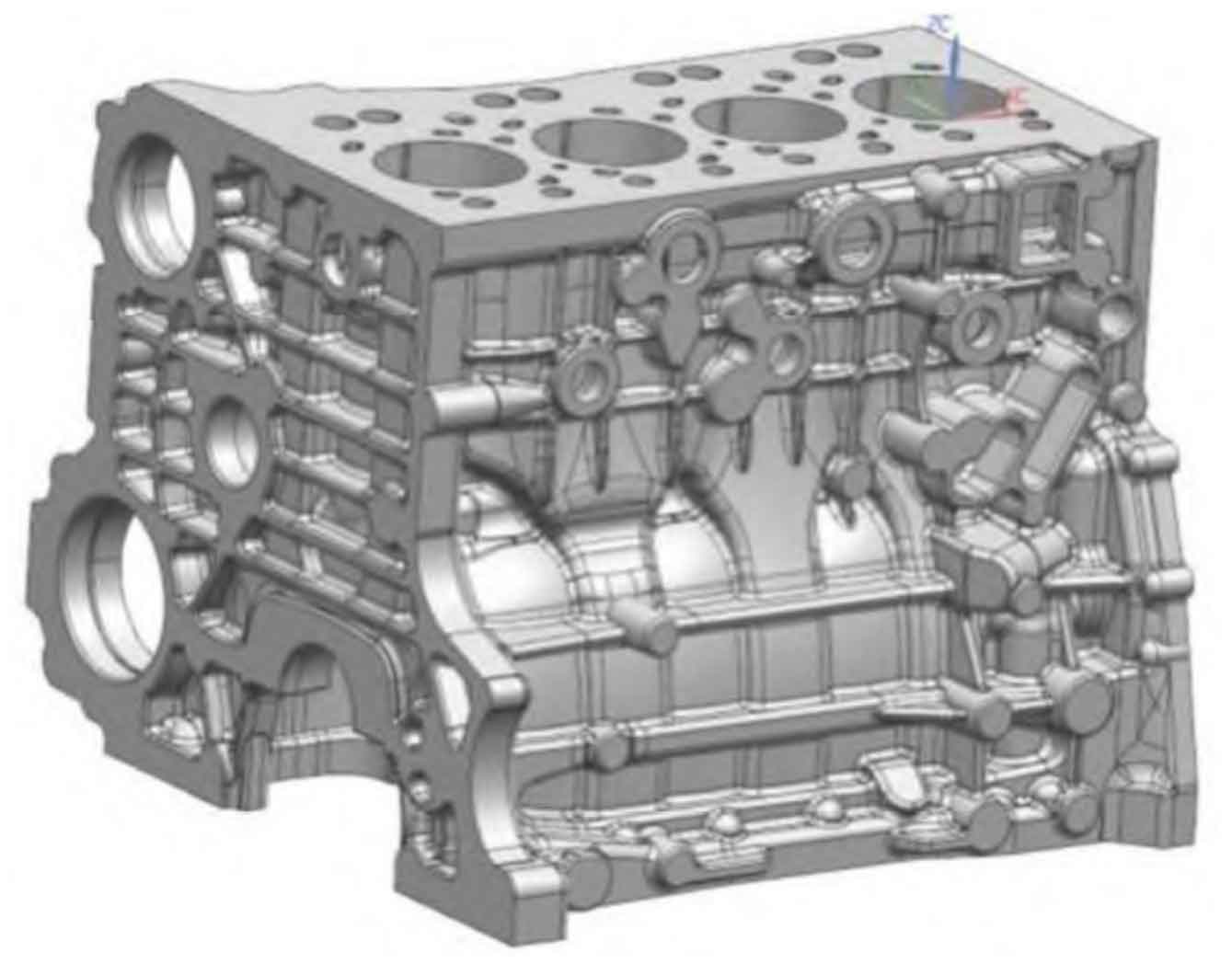

The new generation of cylinder block is a 4-cylinder dry-type cylinder block with material grade of HT300, casting mass of 190 kg and overall dimension of 516 mm × 551mm × 432 mm, with uniform wall thickness and 6 mm thickness. The outline structure of the casting is shown in Figure 1. The tensile strength of the body is required to be greater than 250Mpa, and a total of 18 bolt bosses on the bearing pad surface and top surface need to be tested; There is a penetrating oil and air passage cross arc structure on the side of the cylinder body. During the pouring process, the sand core is easy to deform and fracture under the action of buoyancy; The water jacket is connected with the inner cavity of the water channel, and the transverse channel is narrow. The sand core is required to have high comprehensive performance, otherwise it is easy to cause problems such as sand sticking and sintering, and it is difficult to clean the inner cavity of the channel in the later stage. The rear end is integrated with a gear chamber structure, extending 180 mm outward from the outer surface of the cylinder, with a thickness of 35 mm. Here, hot spots are concentrated and prone to defects such as insufficient pouring or pores. Comprehensive analysis shows that the structure of the cylinder block is complex and the casting process is difficult.