With the rapid development of China’s rail transit equipment, China has been at the forefront of the world in the manufacturing level of complete vehicles such as high-speed rail, subway, light rail and monorail. As one of the most core components of the bogie of rail transit vehicles, the gear drive device is responsible for the power transmission between the motor and the power wheel set during the high-speed operation of the vehicle. For high-speed trains with long transportation distance and large regional span, it is necessary not only to meet the requirements of high integration and lightweight in structural design, but also to meet the reliability and safety of the box under low temperature operation environment, with the minimum operating environment temperature ≤ – 40 ℃. In this paper, a kind of ductile iron casting process for complex thin-walled low-temperature ductile iron box was studied, and the sample production was successfully completed, meeting its technical requirements.

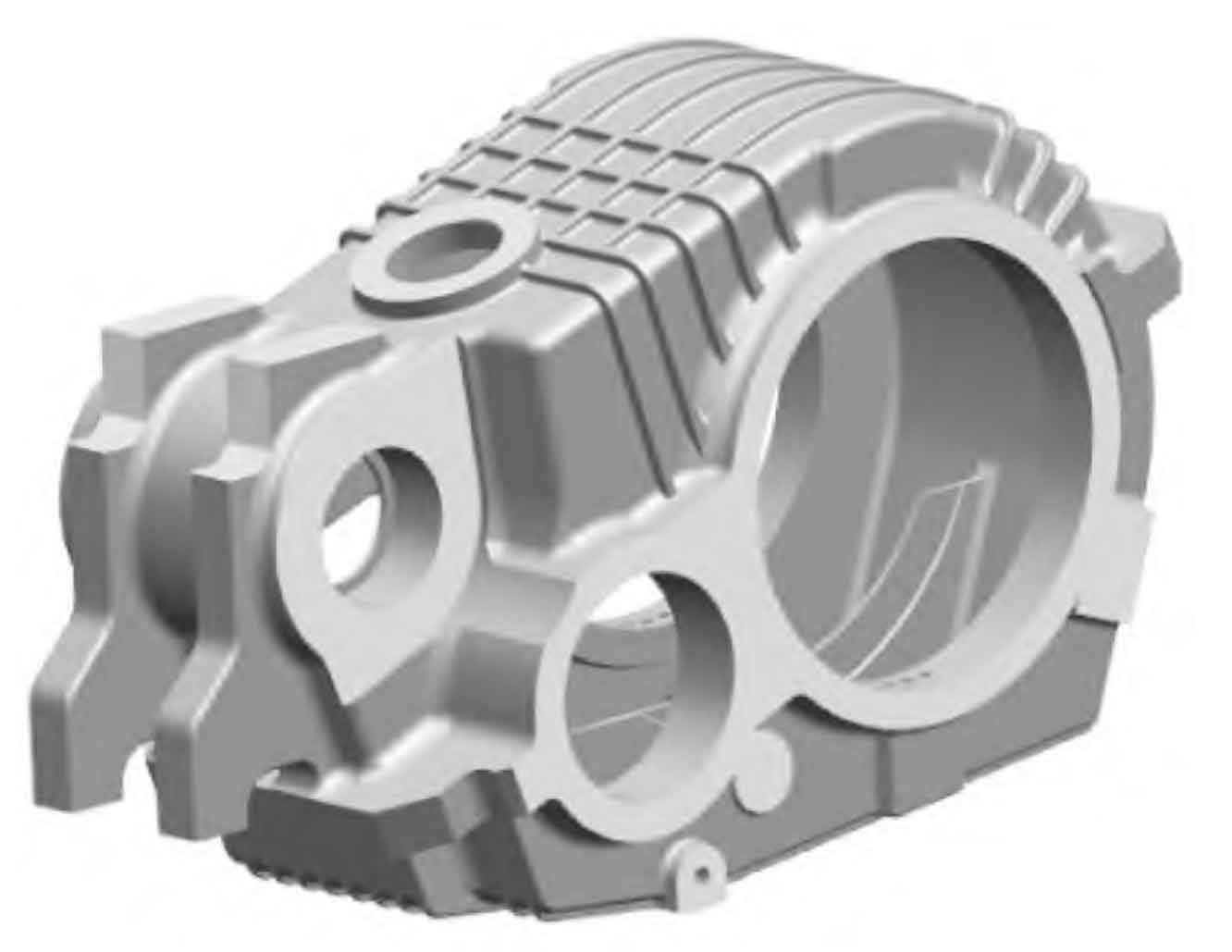

The material grade of the test box is QT400-18L, and the mechanical property requirements are shown in the table. The spheroidization rate of graphite shall not be lower than 85% specified in ISO 945 and the size of graphite shall be more than grade 5. See the figure for the three-dimensional diagram of the box, and the overall dimension of the box is 1100 mm × 850 mm × 400 mm, the weight of ductile iron casting is 256 kg, the main wall thickness is only 10 mm, and the external surface of the box is designed with many 10 mm stiffeners. Large outline size, large weight, long pouring system flow, long pouring time, cold shuts, cold beans, pores, slag inclusion defects are easy to appear in the thin wall area, and graphite floatation, spheroidization and other structural abnormalities are easy to appear in the thick wall area.

| Texture of material | Tensile strength/MPa | Specified plastic extension strength Rp0.2/MPa | Elongation after fracture A/% | Impact absorbed energy at -40 ℃/J |

| QT400-18L | ≥400 | ≥240 | ≥18 | ≥ 12 (average of three samples) ≥ 9 (single sample) |