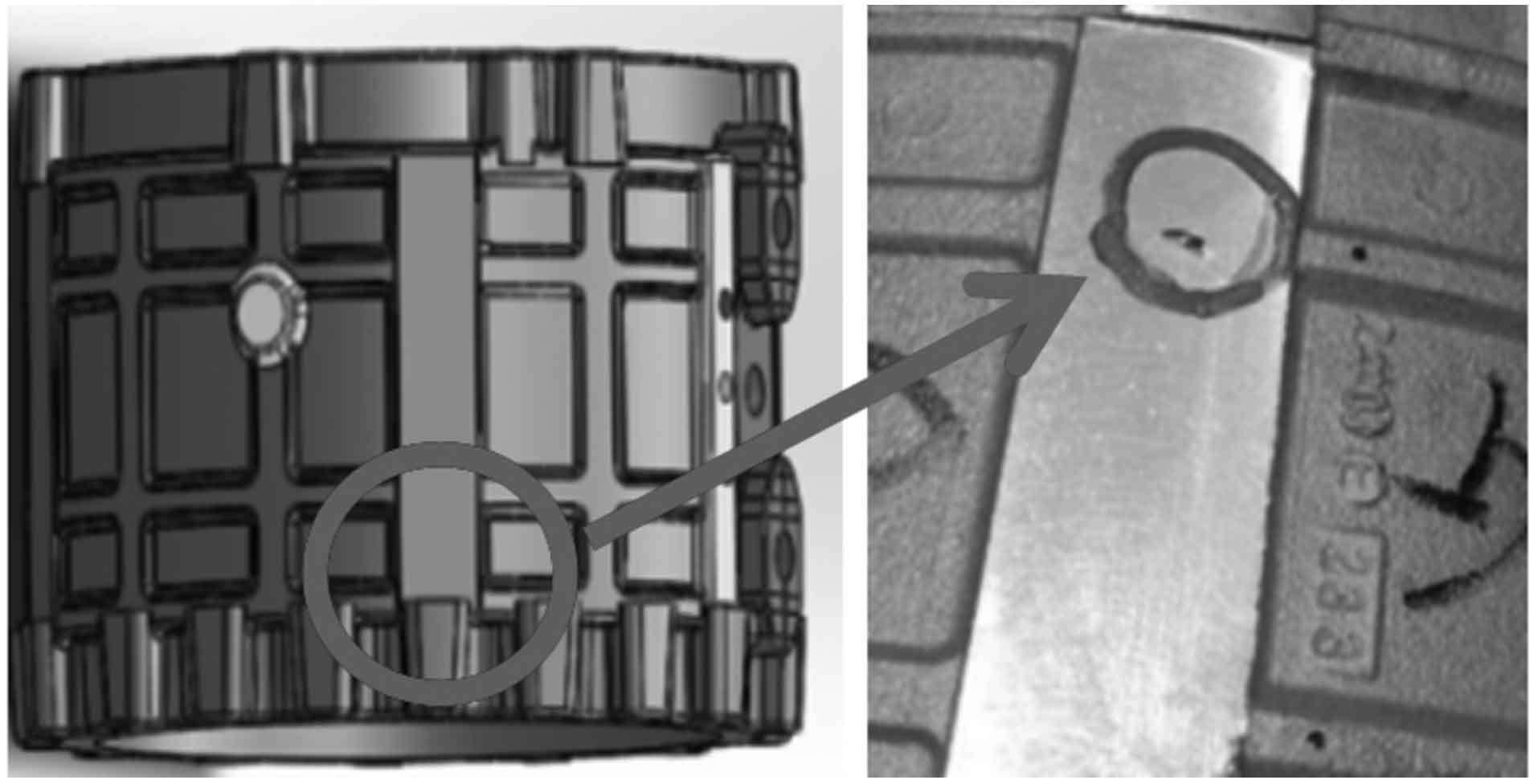

Through the verification of small batch production, from the statistical table of defects, the first defect type is blow hole defects. The main position of blow hole defects is concentrated on the blank plane of the upper mold position of the die, which generally needs to be processed before it can appear. The surface is smooth, oval or irregular holes, as shown in Figure 1.

The gas in the casting process mainly comes from melting process, pouring process and mold. In view of the causes of bad air holes in motor shell, this paper analyzes the causes from the aspects of people, conditions, materials, methods and molds.

1. Analysis from the perspective of people

At present, the gravity casting production process of our company adopts the manipulator to take aluminum water for pouring. The employees place sand cores into the mold cavity every time. Before casting production, the employees check and confirm the equipment parameters of the casting machine and operate according to the operation instructions to ensure that there are no quality problems in the operation process. Human factors are not the main reason.

2. Analysis from the perspective of materials

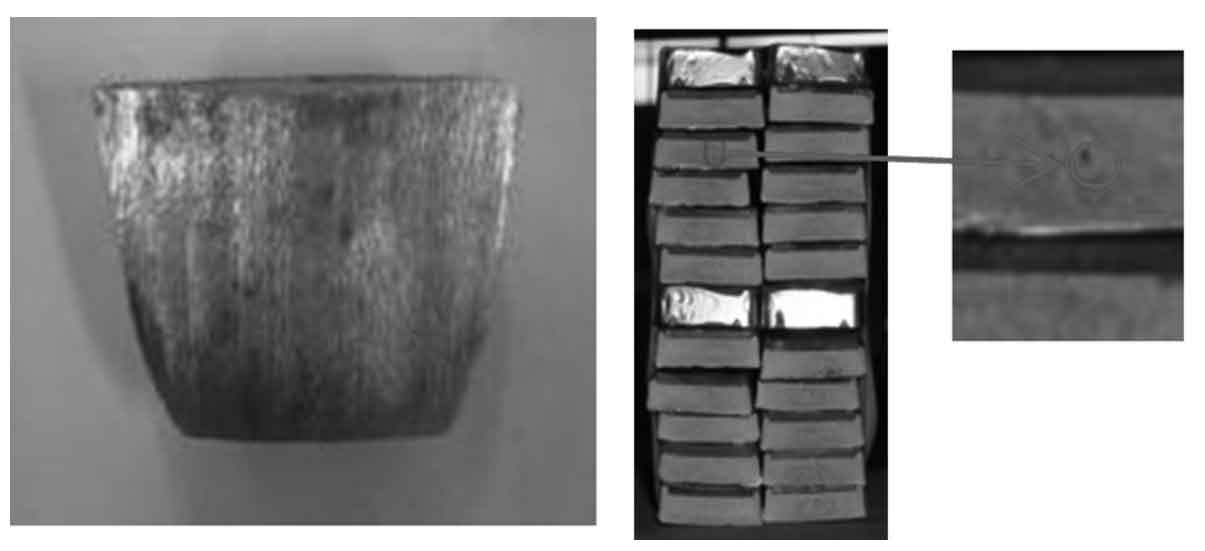

In the smelting process, the gas mainly comes from various furnace charges, furnace gas, furnace lining, tools, flux and hydrocarbons produced by the combustion of moisture, nitrogen, oxygen and hydrogen in the surrounding atmosphere. When aluminum is above 400 ℃, the reaction between metal and water vapor can occur to produce gas. Check that the hydrogen and slag content of molten aluminum and the composition specification of molten aluminum are within the qualified range. Smelting and molten aluminum are not the main reasons, as shown in Figure 2.

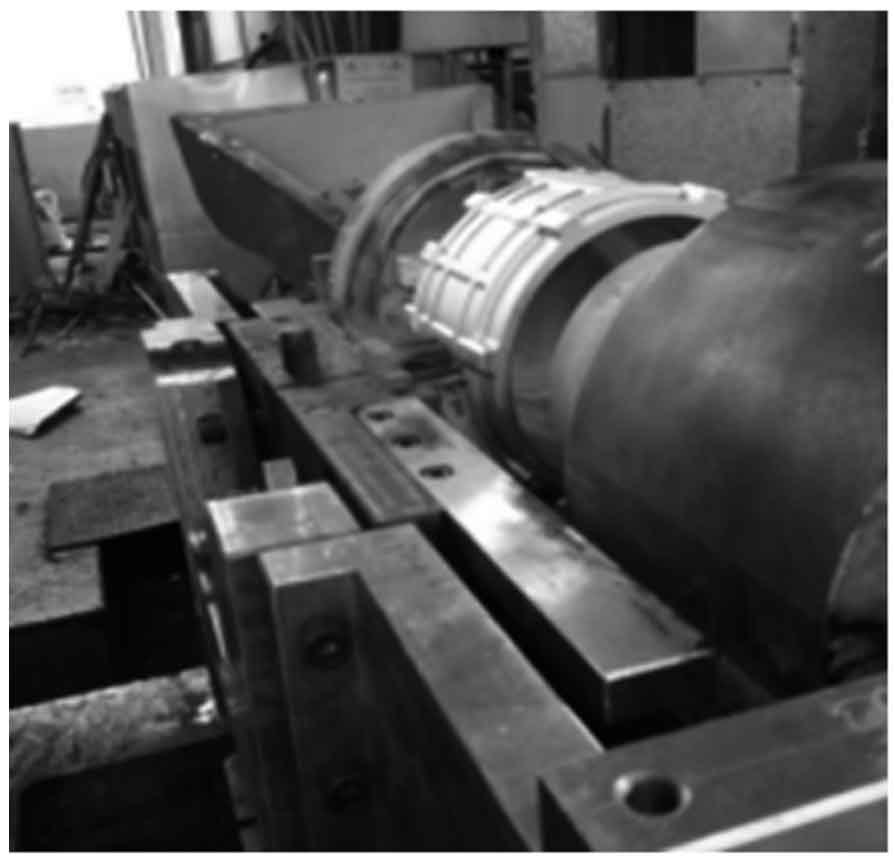

The casting process of motor shell needs to be combined with sand core to cast. Because the sand core material needs resin binder bonding, in the casting process, the water in the molding sand and the binder produce a large amount of gas under the thermal action of metal liquid. If the binder content in the mold is increased, the gas evolution will increase; High pouring temperature produces a large amount of gas. The binder with the largest gas generation also often has the fastest gas generation rate. Large gas generation and high gas generation rate will cause large back pressure at the metal mold interface and often cause blow hole defects. For example, it will lead to the formation of invasive blow hole defects in the casting. Therefore, the amount of gas output from sand core is one of the main reasons for poor porosity, as shown in Figure 3.

3. Analysis from casting condition parameters

The motor shell is cast with aluminum liquid and poured by manipulator. Check the production process, manipulator stroke, action continuity, pouring time and other recorded parameters, which are not the main factors within the specification range. According to the surface appearance inspection of the casting, it is confirmed that there is no appearance quality problem between the casting body and the riser. It is ruled out that the pouring speed is too slow or there is cut-off during pouring, resulting in poor appearance quality.

4. Analysis from mold and gating system

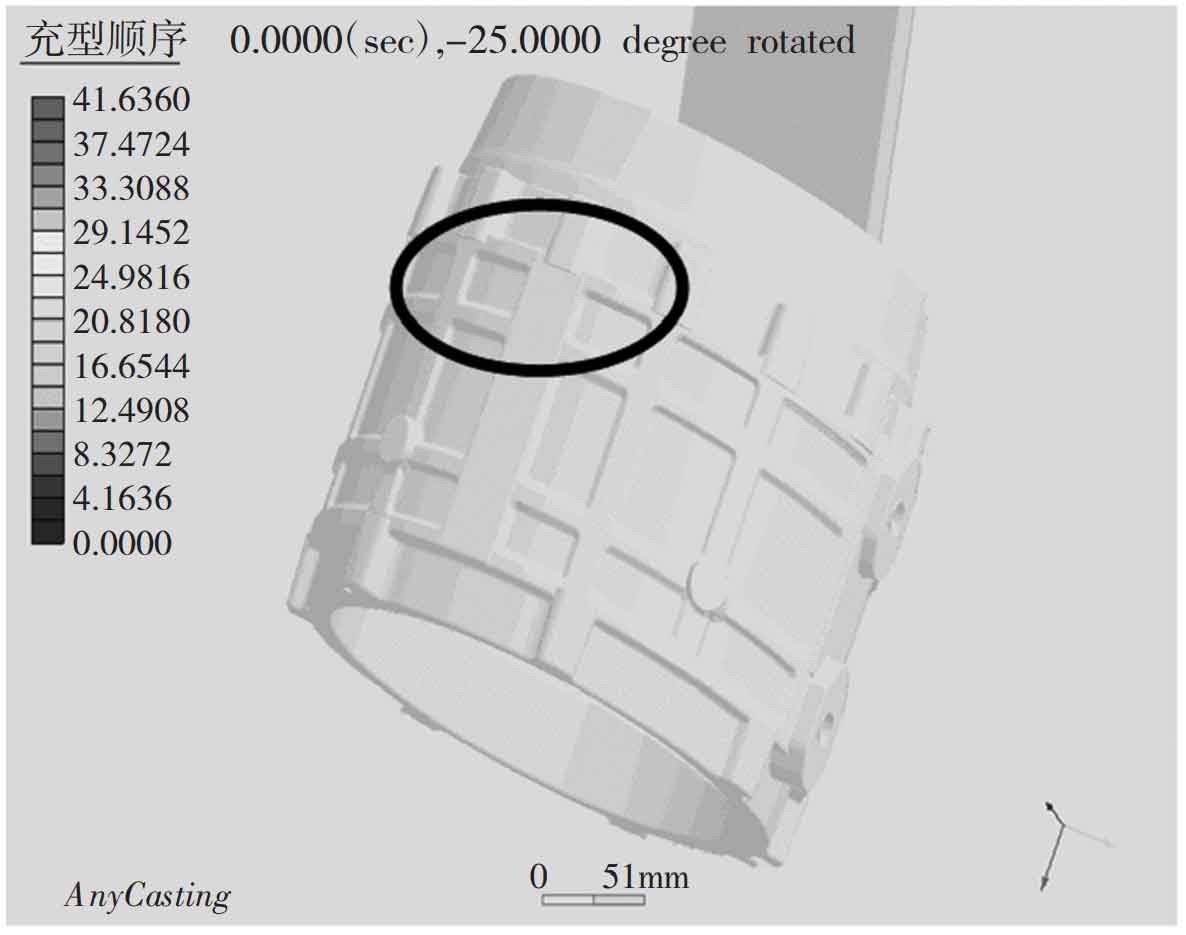

Analysis of gating system: the runner adopts semi closed gating system, and the inner runner is located on the gear surface of the casting. The sprue is a small cone at the top and a large cone at the bottom, which can be filled quickly. The choke section for controlling the flow is at the outlet of the slag collector. According to the analysis results of the mold flow software AnyCasting, the aluminum water in the early stage of the sprue enters from the bottom of the inner sprue, divides into two sides and gradually fills up, resulting in turbulence, air wrapping and suction of the aluminum water, resulting in the gas concentrated on the mold and unable to be discharged smoothly. The unreasonable design of mold and gating system is one of the main reasons, as shown in Figure 4.

5. Analysis from the perspective of method

According to the confirmation of the parameters set in the casting site operation documents and casting conditions, the parameters recorded by the on-site staff, the operation documents and the parameters set by the casting machine are within the specification range and there is no abnormality. Insufficient casting operation standards are not the main factor.