The nodular iron castings of wind power wheel hub belong to thick and large section castings, especially the thickness of the main shaft hole is even more than 200 mm. With the large-scale development of wind power in the future, the size and weight of the key nodular iron castings will become larger and larger.

Wind power ductile iron castings have large geographical span, complex operating conditions and poor conditions. The high latitude and high cold area represented by Northern Europe, Russia and the three north of China, and the extreme climate conditions such as high salt, high humidity and high corrosion, typhoon and tsunami represented by the south of the Yangtze River and the sea of China all put forward higher requirements for wind power ductile iron castings, especially for low-temperature impact toughness. The hub nodular iron castings bear complex alternating loads and have high requirements for reliability. The weight of the hub nodular iron castings is generally 10 ~ 60 T. during the operation of wind power, the blade flange hole and main shaft hole bear huge and complex alternating loads, so they must have good mechanical properties and internal quality, as shown in Figure 1.

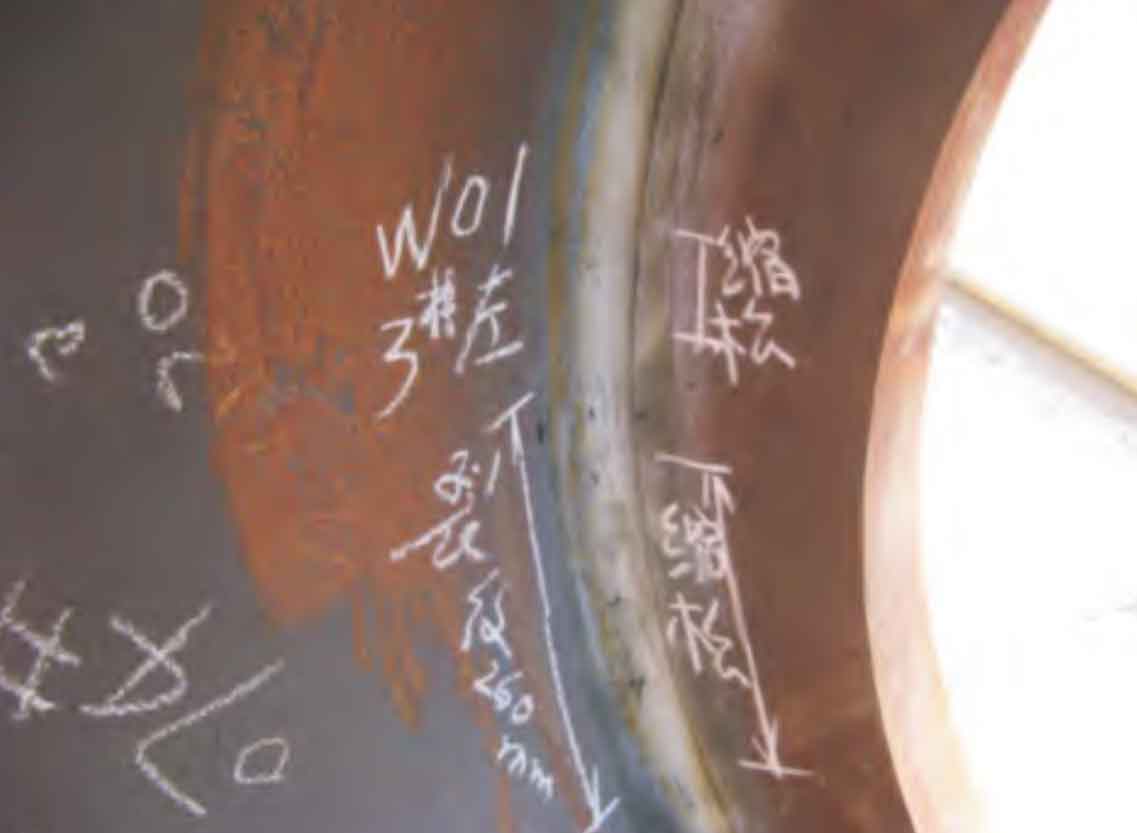

The hub casting belongs to thick nodular cast iron. However, due to the large outline size and uneven wall thickness of the hub nodular cast iron, it can not solidify at the same time. The thick parts, isolated hot spot areas, grooves on the nodular cast iron and parts with difficult heat dissipation of sharp angle sand are prone to shrinkage and porosity, which can not meet the requirements of ultrasonic flaw detection. Figure 2 shows the surface shrinkage at R in a certain type of hub.

Nodular cast iron is easy to oxidize and produce slag inclusion. The primary slag can be easily controlled through smelting, filtration and other measures. The secondary slag inclusion is the key and difficult point of control. The secondary oxidation slag inclusion is generally distributed on the upper surface of the pouring position of nodular iron castings, below the core and at the dead corner of nodular iron castings. The section presents dark black and matte inclusions with different depths, which are distributed intermittently. During magnetic particle flaw detection, the magnetic marks are distributed in strips. The more stripes, the coarser and the denser the accumulation, indicating that the slag inclusion is more serious. See Fig. 3 for typical magnetic particle flaw detection photos of secondary oxidation slag inclusion.

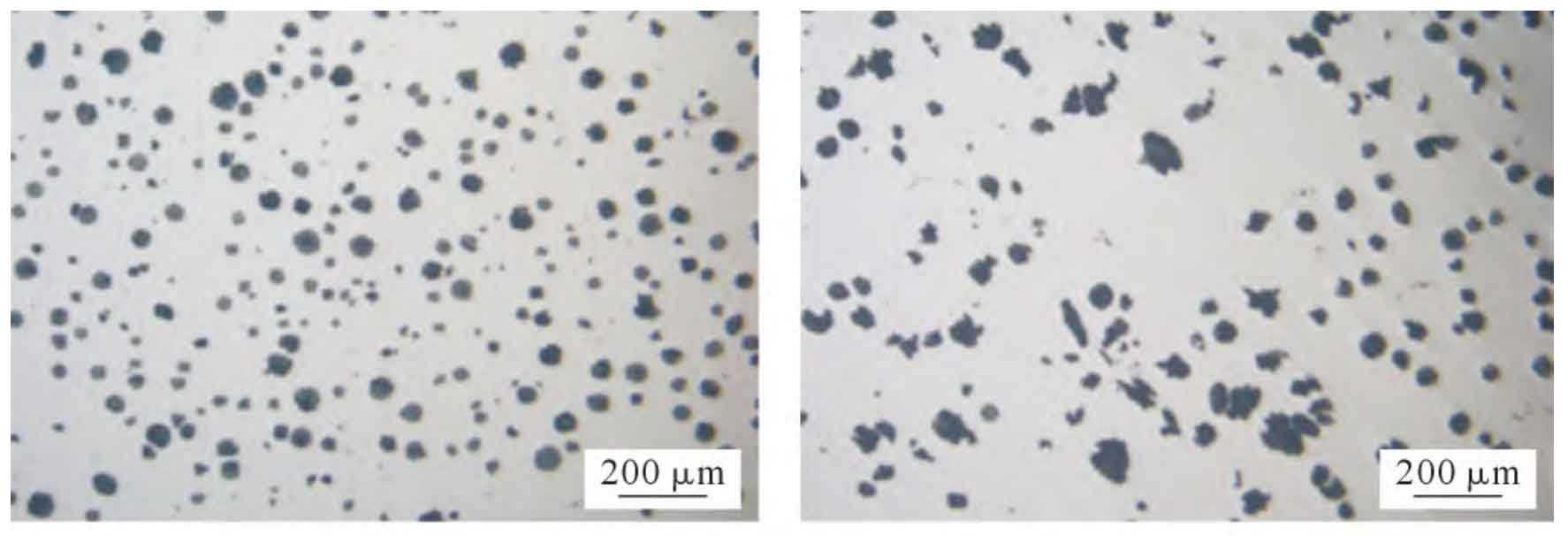

The nodular iron castings of wind power wheel hub are generally made of qt400-18al and qt350-22al grades, and there are also requirements for composite materials. For example, qt400-18 is selected for strength, and the impact toughness is – 30 ℃ or – 40 ℃, which is prone to the contradiction between tensile strength, yield strength, hardness and impact toughness, and has high requirements for the control range and stability of process parameters. The nodular cast iron of wind power hub belongs to large-size and large section nodular cast iron. The nodular cast iron has large pouring weight, large heat capacity and long solidification time. It is easy to have problems such as coarse structure, graphite variation and graphite floating. Figure 4 shows the change of graphite morphology from surface to core of a wheel hub nodular iron casting.