The coupler body of type 17 coupler is a complex medium and small steel casting with the overall size of 975 × five hundred and seventy-four × 496mm, with a single piece weight of 190kg. The steel casting structure includes three parts: hook head, hook body and hook tail. The structure of hook head is complex. There is a cavity in the hook body, with uneven wall thickness and large hook tail thickness. The minimum wall thickness of parts is 10mm and the maximum is 45mm.

Through production practice and practical application, it is found that cracks are easy to occur at the root of the traction table in the hook cavity, near the hook ear hole, the lower locking pin rib and the junction between the hook head and the hook body; The side of the hook cavity, the end of the hook tail and the pin hole of the hook tail are easy to be worn. These parts are sensitive parts for the use of parts, so they are required to have high sand casting quality. Casting defects should be avoided in the above parts in production.

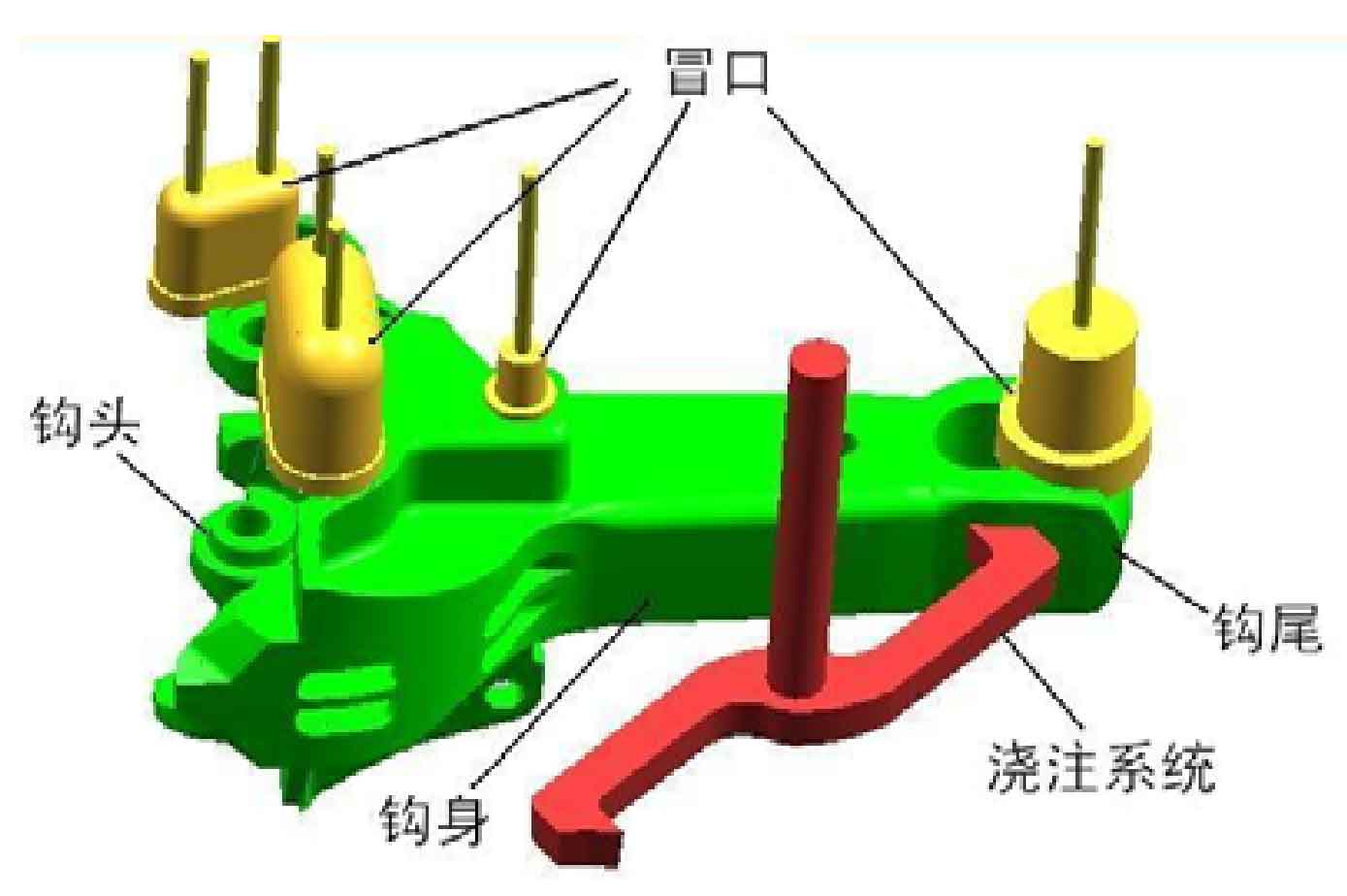

The original sand casting process adopts one box of two pieces to ensure the production rate of sand casting process. The structure of the hook head is complex. For the far end of the casting, the wall thickness changes greatly. Three ordinary risers are set to ensure solidification and feeding. The wall thickness of the hook tail is large, close to the gate, and finally solidified. Therefore, ordinary risers are also set at the hook tail. In actual production, they are set at the root of the traction table in the hook cavity and near the hook ear hole External cold iron shall be set at the parts where cracks are easy to occur, such as the rib of the lower locking pin and the junction between the hook head and the hook body, so as to avoid the formation of hot joints. The original sand casting process of the hook body is shown in the figure. In order to simplify the simulation calculation, the 1 / 2 rotational symmetry model is adopted.