The simulation analysis of the temperature field of the frame in sand casting includes the solidification of the frame in the mold cavity, the sand falling after cooling to the riser center temperature drops to a certain temperature, and the process after sand falling. In the simulation calculation, the temperature field analysis of sand casting frame only includes two processes: the complete solidification of sand casting in the mold cavity and the drop of riser center to a certain temperature. The temperature field analysis mainly includes temperature distribution cloud diagram, temperature curve at typical time, solidification result analysis and shrinkage porosity analysis of sand casting.

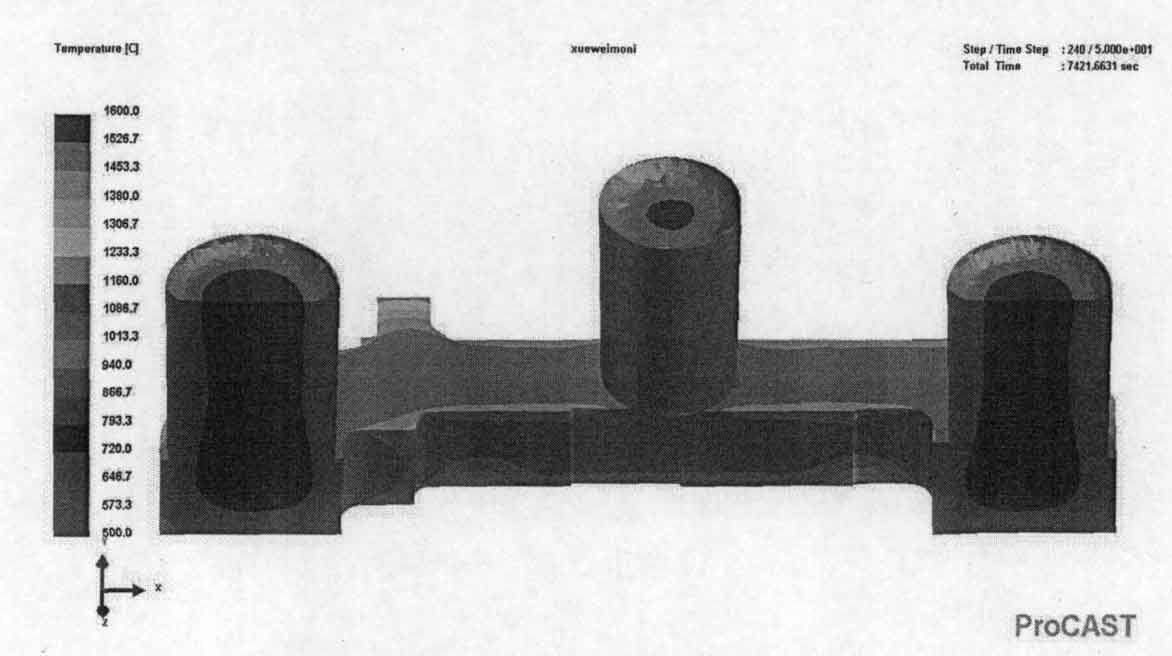

After the simulation of solidification process of sand casting frame, the temperature results at typical time are processed and analyzed. As shown in Figure 1, the temperature field distribution of the sand casting frame during solidification for about two hours is shown. It can be seen from the figure that in the early stage of solidification, the cooling of the sand casting frame is affected by the sand box. The cooling starts at each edge and protruding corner of the sand casting frame first, and the temperature at the large fillet outside the beam decreases rapidly due to chilling. The temperature at the inner fillet of the sand casting frame changes slowly, the temperature distribution of the large and small risers begins to change, and the root of the small riser begins to solidify.

According to the temperature field distribution at this time, the liquid metal at the riser has decreased by about 1 / 10 of the whole riser length due to solidification shrinkage. In the actual process production, the riser needs to be supplemented with liquid metal, that is, the riser needs to be supplemented. The temperature in the riser is improved after the riser is patched, which can better feed the sand casting frame and avoid the occurrence of shrinkage porosity in sand casting.

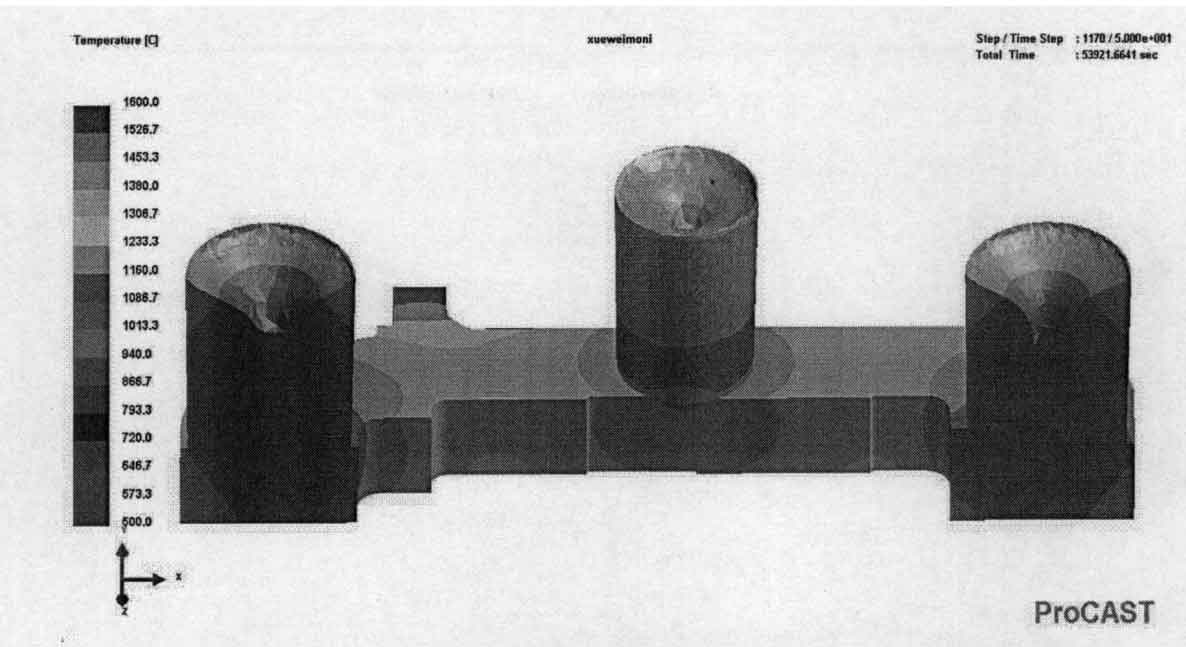

Figure 2 is the temperature distribution diagram of the sand casting frame at the middle time of the whole solidification time (about 15 hours). It can be seen from the figure that in the middle of solidification, due to the symmetrical arrangement of sand cooling iron on the column of the sand casting frame, the solidification sequence has changed, and the sand casting starts from the middle of the large and small risers; Start cooling towards the root of the large and small risers, and the solidification speed of the root of the large and small risers is faster than that of the center of the riser. The temperature at the outer protruding part of the column decreases the fastest. At this time, it has dropped to about 1150 ℃, the temperature between the large and small risers is about 1300 ℃, and the temperature at the center of the riser is the highest, which is still greater than 1500 ℃.

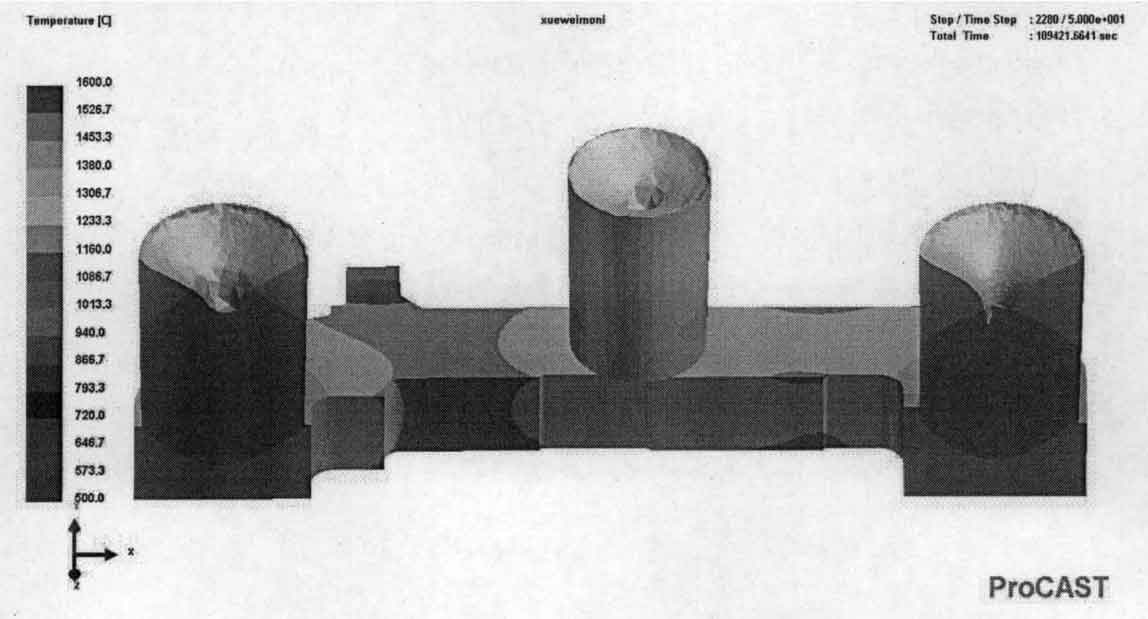

Figure 3 shows the temperature distribution cloud diagram of sand casting at the end of solidification. At this time, the column and beam of sand casting frame have been completely solidified. The temperature value of the protruding part on the outside of the sand casting frame is the lowest, and the temperature in the middle of the large riser is the highest. Similarly, affected by the external chill, the temperature begins to drop rapidly from the middle of the large and small risers. Until the temperature of the whole sand casting frame reaches the sand dropping temperature.