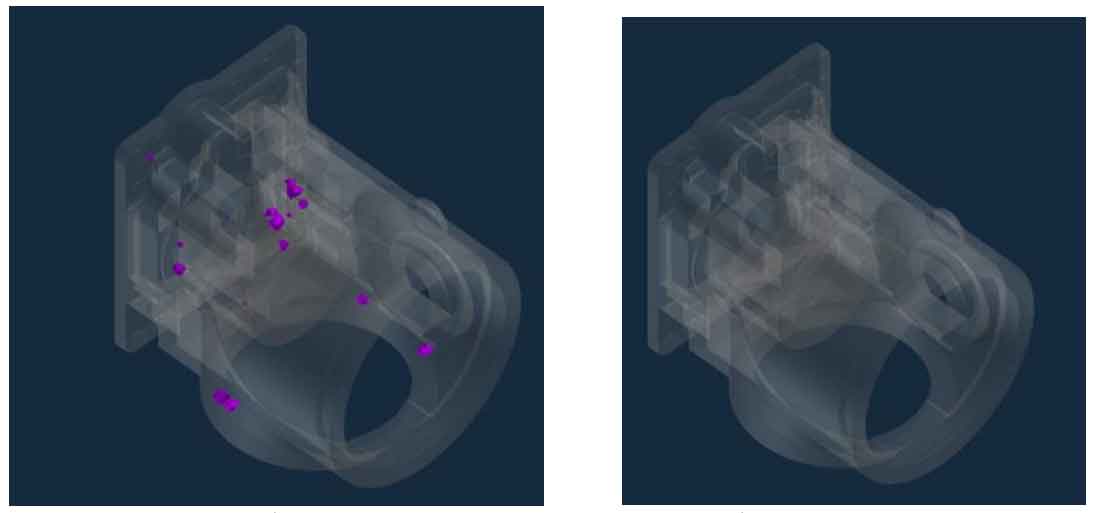

The gating system of the optimized two pouring schemes after adding riser and cold iron is re meshed, sand casting parameters are set and pouring process simulation calculation is carried out with ProCAST simulation software, and sand casting defects are checked and analyzed with viewer module in ProCAST software. Scheme I closed gating system The schematic diagram of solidification defects of axle housing after optimization of semi closed gating system in scheme 3 is shown in Figure 1.

As shown in Figure 1, the shrinkage defects of axle housing in the optimized scheme I are reduced, but they are not completely eliminated. There are large shrinkage defects near the numerical flange in the inner cavity of the cylinder. In scheme 3, the sand casting defects of the axle housing have disappeared, the original shrinkage porosity and shrinkage cavity have been transferred to the riser, and the shrinkage porosity at the hot joint has been almost eliminated, which shows that the riser and cold iron have played a good role in feeding and cooling the axle housing respectively, and the purpose of eliminating the solidification defects of the axle housing has been achieved, From the optimization results, it can be seen that the sand casting effect of the optimized scheme three semi closed gating system is better than that of the sand casting scheme one closed gating system.

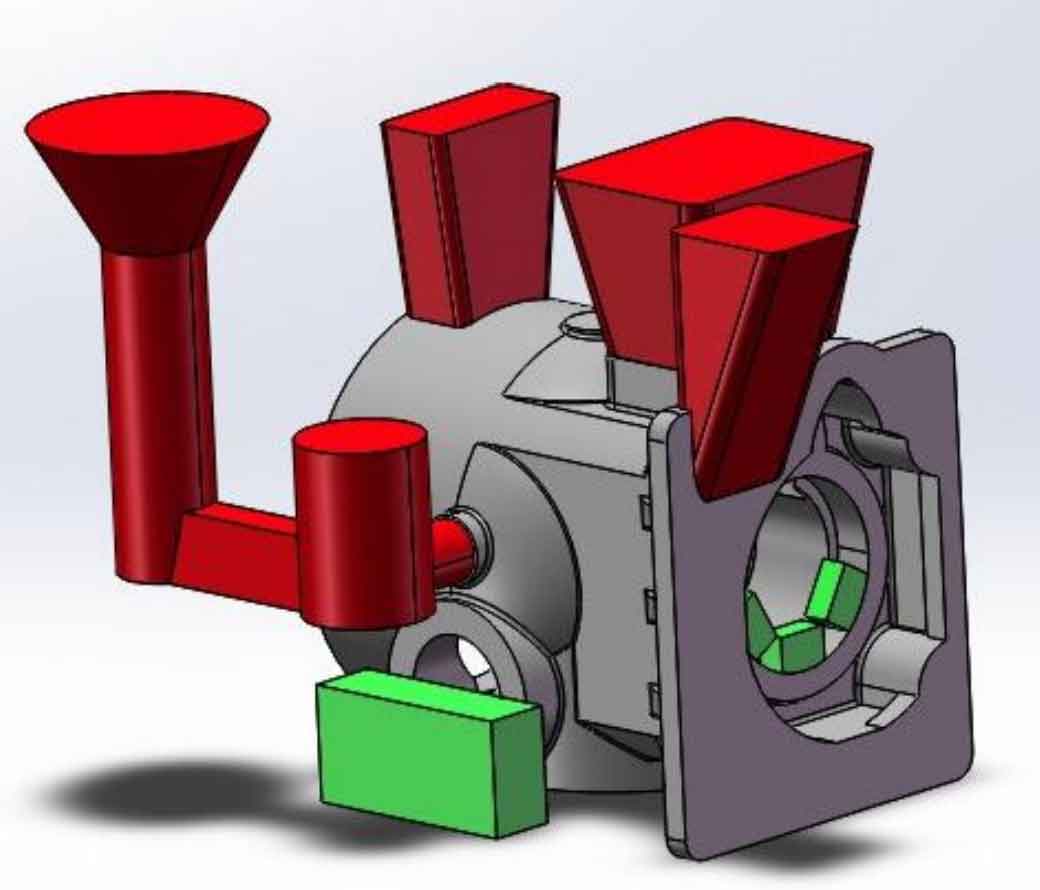

As shown in Figure 2, the red part is the gating system and the green part is the cold iron. The tractor split axle housing is made of cast steel zg40 Mn, with a pouring temperature of 1580 ℃ and a pouring time of 10 seconds; One in one box, the gating system is designed as a semi closed gating system; Proportion of sprue cross-sectional area: ∑ a inner: ∑ a transverse: ∑ a straight = 1:0.8:1.2; The gating system of sand casting has one sprue, one transverse sprue and one inner sprue. The cross-sectional area of the inner sprue is 22.5 cm2, the cross-sectional area of the transverse sprue is 18 cm2 and the cross-sectional area of the direct sprue is 27 cm2. The sand casting riser is designed as a combination of open riser and concealed riser for feeding. The concealed riser is distributed at the inner sprue and can collect sand at the same time. The open riser is located on the upper surface of the axle housing, the internal cooling iron is placed at the inner cavity of the axle housing, and the external cooling iron is placed at the place with large wall thickness.