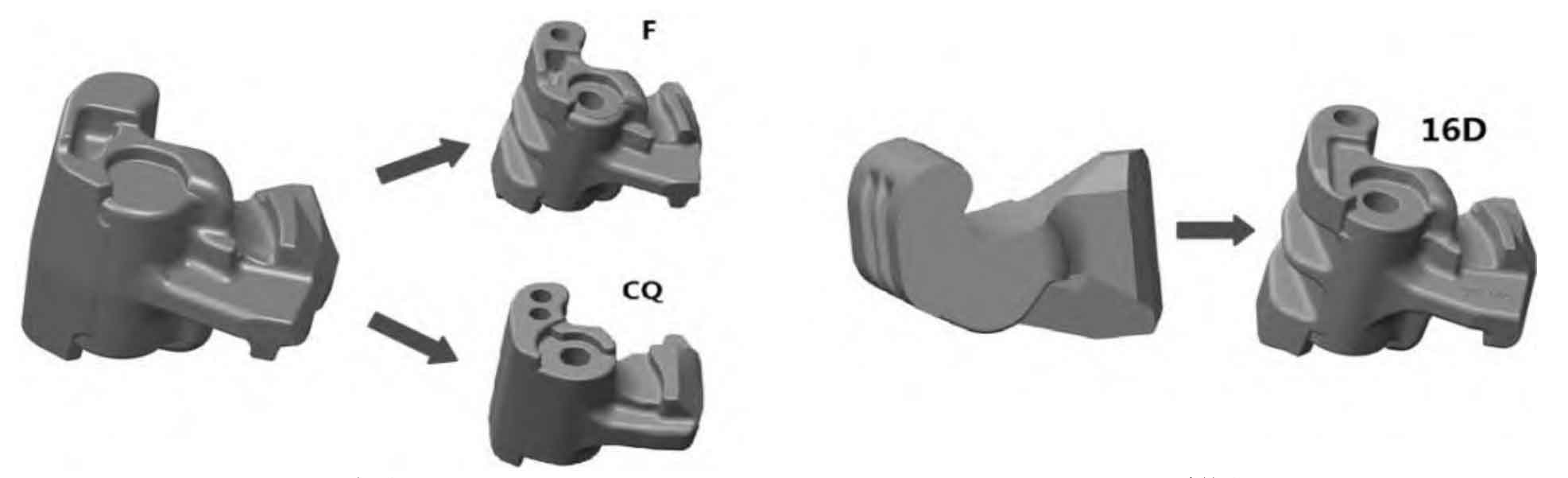

At present, F and CQ type knuckle are forged vertically and 16D type knuckle is forged horizontally, as shown in Figure 1.

When vertical forging is used for forming, except for coupler knuckle pin hole and flag hole, machining allowance shall be reserved for all positions. When drawing the line, take the blank surface of the traction table and the impact table as the benchmark, and at the same time refer to the internal and external S surface to determine the coupler knuckle pin hole, and then take the coupler knuckle pin hole as the benchmark to complete the processing procedures of the locking surface, the internal S surface, the external S surface (the F type coupler knuckle is added with the processing procedure of the weight reduction groove), the impact and the traction table. When transverse forging is adopted, except for the coupler knuckle pin hole and flag hole, there is no machining amount on the outer S surface, and the machining amount on the inner S surface is 1-2 mm. The machining amount on the traction table and the locking surface is large.

When drawing lines, determine the coupler knuckle pin hole based on the internal and external S surface, and then complete the machining process of seat lock surface, internal S surface, impact and traction table based on the coupler knuckle pin hole.

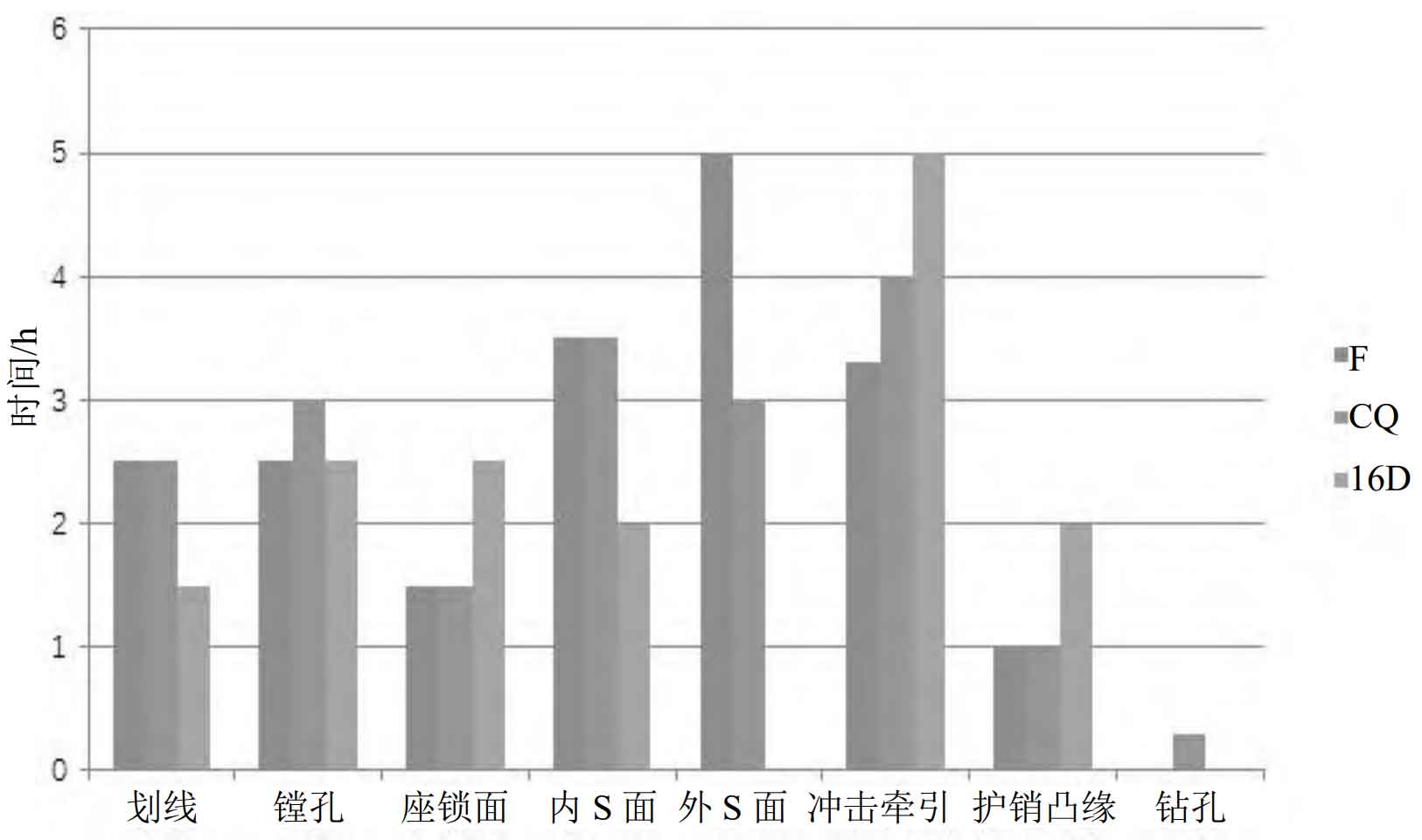

The total processing time of the three forged knuckle is 25.9 h, 26.8 h and 25.5 h, respectively, according to the on-site description of the processing time beat of the three forged knuckle. The specific time beat of each process is shown in Figure 2.

It can be seen from Figure 2 that the total processing time of the forged knuckle of horizontal forging and vertical forging is not different. Each position of the vertical forging knuckle needs to be processed. The S surface (including the weight reduction groove) outside the horizontal forging knuckle does not need to be processed for forging, but the processing amount of the impact table, traction table, and guard pin flange is large. The advantages and disadvantages of the manufacturing process of horizontal forging and vertical forging knuckle are shown in the table.

| Forging mode | Advantage | Disadvantage |

| Cross forging | Short forging process (high efficiency), low energy consumption (once heating), good surface quality, easy to draw lines to determine the coupler knuckle pin benchmark, no machining amount on the outer S surface, and small machining amount on the inner S surface. | The mold cost is slightly higher, and the processing amount of traction table, impact table and retaining pin flange is relatively large. |

| Vertical forging | Long forging process (low efficiency); High energy consumption (heating twice); Poor surface quality; It is difficult to determine the benchmark of coupler knuckle pin hole, and multiple dimensions are needed; Due to the forging draft angle of the inner and outer S surfaces, the intermediate processing amount is large, and the two ends are small, so the processing amount is uneven; The weight reduction groove of F-type forged coupler knuckle needs to be machined. | Schematic Diagram of Horizontal Forging and Vertical Forging. |