During the operation of the unit, the left and right sides of the casting diaphragm will produce stress under different pressures. If the stress is too large, the gap position between the diaphragm and the casing will be damaged. If the axial and radial deformation of the casting diaphragm is too large, the casting diaphragm will collide with other adjacent parts. Therefore, in order to determine the dangerous working conditions, it is necessary to comprehensively evaluate the stress, axial deformation and radial deformation of the casting diaphragm. In order to determine the appropriate cutting thickness, it is necessary to analyze the mechanical properties of casting diaphragms before and after repair welding under different cutting thicknesses. If the analysis is carried out under two working conditions for different cutting thicknesses, the analysis time will be increased and the analysis efficiency will be reduced. In order to improve the analysis efficiency, the cast diaphragms of the original structure are first analyzed, and the stress and deformation of the cast diaphragms under the two working conditions are qualitatively compared, so as to select one of the dangerous working conditions, and then the analysis and comparison of different cutting thicknesses are carried out for this dangerous working condition.

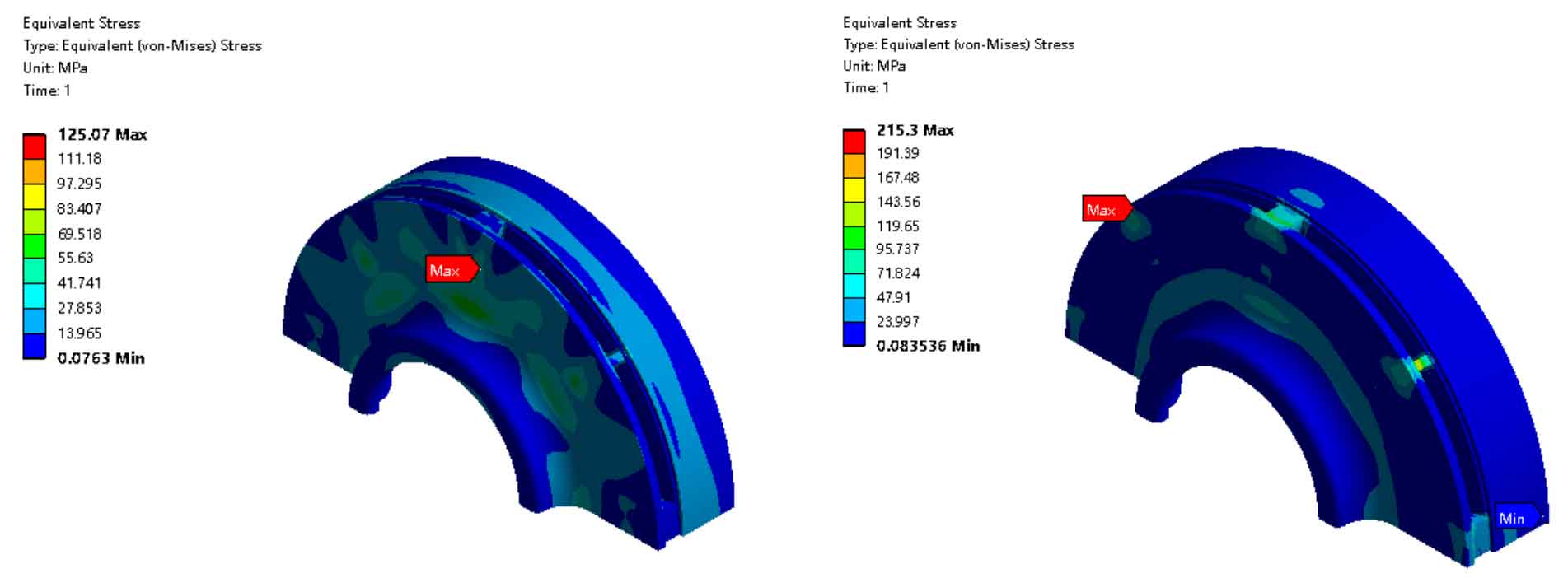

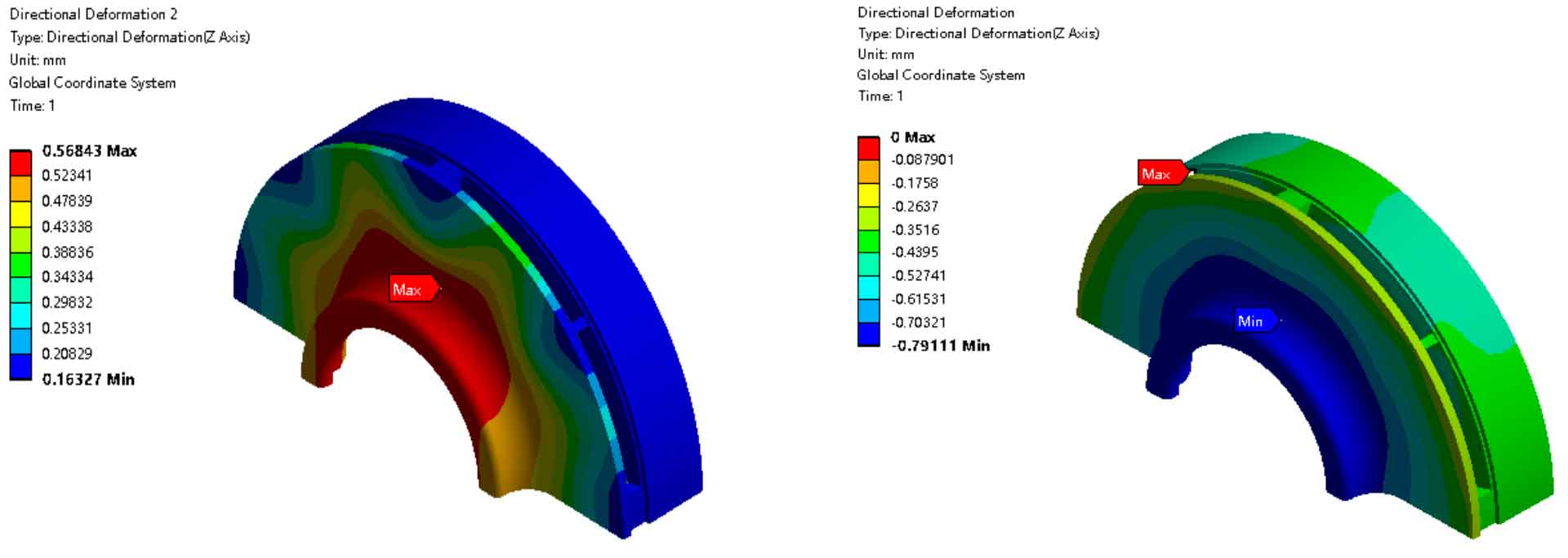

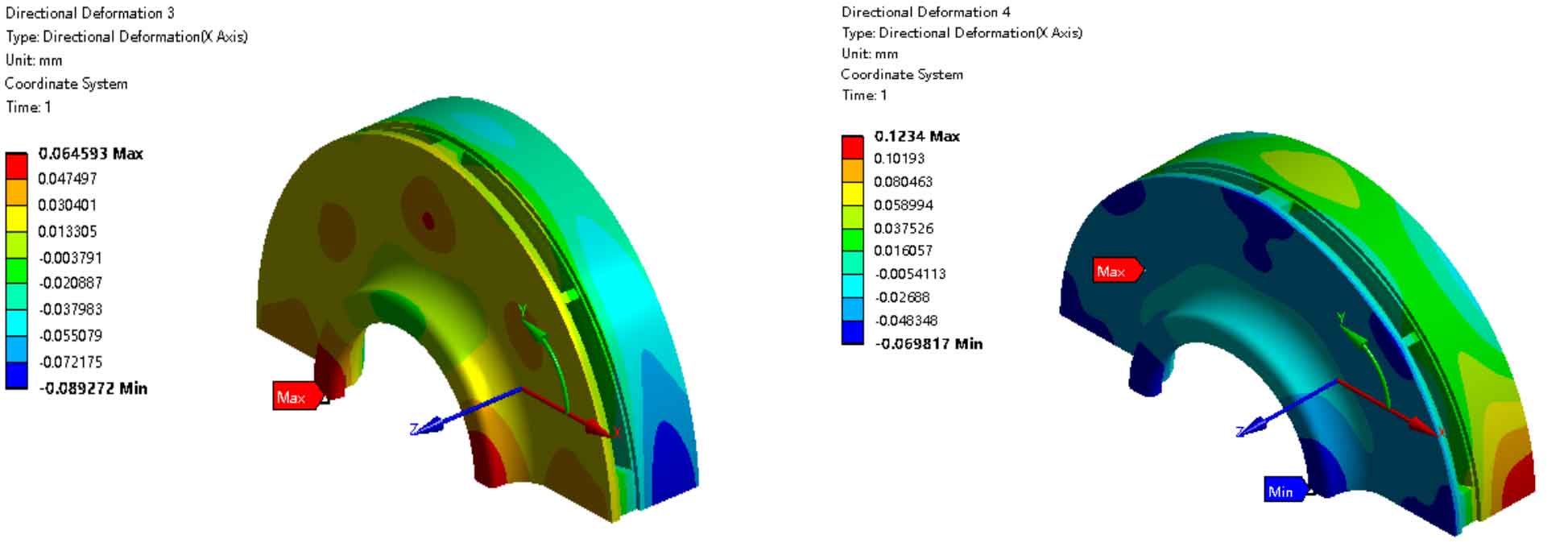

Through analysis, the equivalent stress, axial deformation and radial deformation of the casting diaphragm under operating conditions and venting conditions are obtained, as shown in the figure.

(b) Cloud Chart of Equivalent Stress Distribution of Diaphragm under Vent Condition

(d) Cloud Chart of Diaphragm Axial Deformation Distribution under Vent Condition

(f) Distribution nephogram of diaphragm radial deformation under venting condition

The analysis results under two working conditions are summarized in the table. Observe the analysis results. From the numerical point of view, the maximum equivalent stress, maximum axial deformation and maximum radial deformation under the venting condition are greater than the analysis results under the operating condition. Wherein, the axial deformation under venting condition is negative, which means that the axial deformation direction of the casting diaphragm is from the inlet side to the outlet side. If the radial deformation is negative, it means that its direction is from outside to inside. For the intake diaphragm, the impeller adjacent to the casting diaphragm is on the outlet side. Therefore, when the axial deformation and radial deformation of the inner hole of the casting diaphragm are negative, the gap between the mouth ring seal connected to the casting diaphragm and the impeller will be reduced. If the deformation is large, there is a risk of rubbing. When the axial deformation and radial deformation of the inner hole of the casting diaphragm are positive, there is no such risk. Based on comprehensive consideration, it is determined that the venting condition is a dangerous condition. The cast diaphragms with different cutting thickness and repair welding thickness under the venting condition will be analyzed below.

| Analysis condition | Maximum equivalent stress/MPa | Maximum axial deformation of inner hole/mm | Maximum radial deformation of inner hole/mm |

| Operation | 125 | 0.57 | 0.06 |

| Vent | 208 | -0.89 | -0.08 |