The investment casting material K438 of turbine guide is a nickel-base superalloy widely used in aerospace and has excellent high-temperature mechanical properties. The chemical composition of the alloy is shown in the table. K438 alloy contains a large number of refractory metal elements such as tungsten, molybdenum, niobium and tantalum. The melting process is complex. The alloy will solidify within a certain crystallization temperature range, and there is a solid-liquid two-phase zone. If the volume reduction caused by solidification shrinkage is not supplemented by liquid metal in time, shrinkage porosity and shrinkage defects will be formed in the investment casting of turbine guide. Moreover, due to the different cooling rate of investment casting of turbine guide, complex phase transformation process will occur and different as-cast structures will be formed. The grain size of the investment casting of the turbine guide affects the mechanical properties such as material strength and plasticity. In actual production, the thin blade part is easy to form fine grains, which cannot meet the high temperature strength requirements of the metal, while the thick disk part forms coarse grains, which cannot meet the requirements of yield strength and fatigue performance, and reduces the product qualification rate. By changing the melting superheat, pouring temperature, mold preheating temperature, the size of the investment casting of the turbine guide and setting chills, adjusting the cooling rate of the investment casting of the turbine guide can control the grain size and improve the properties of the alloy.

| Cost | C | Cr | Co | W | Mo | Al | Ti | Nb | Ta | B | Zr | Ni |

| Content | 0.10-0.20 | 15.5-16.5 | 8.9-9.0 | 2.4-2.8 | 1.5-2.0 | 3.2-3.7 | 3.0-3.5 | 0.6-1.1 | 1.5-2.0 | 0.005-0.015 | 0.05-0.15 | Allowance |

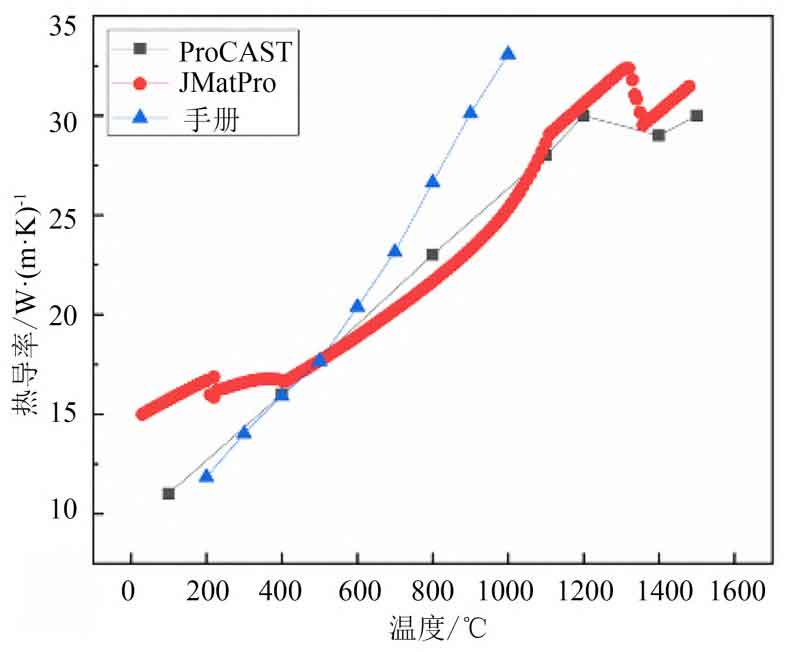

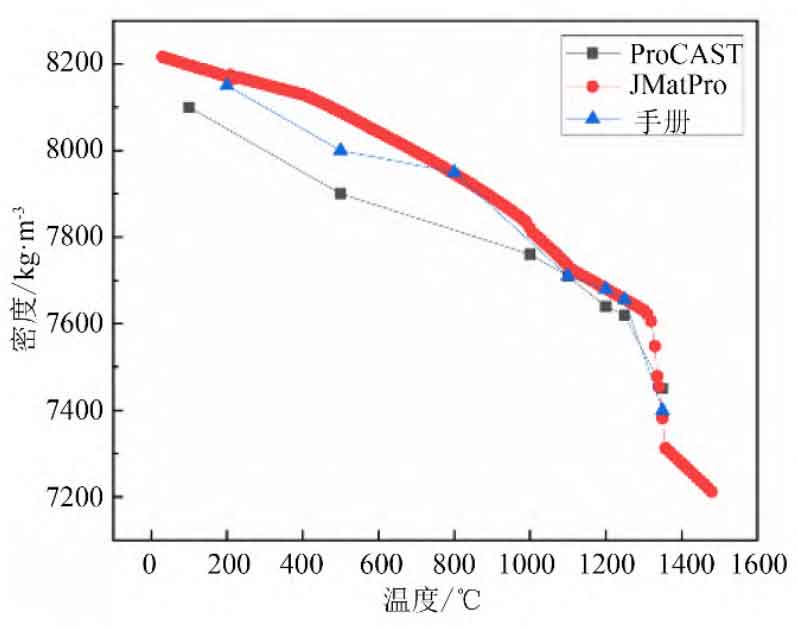

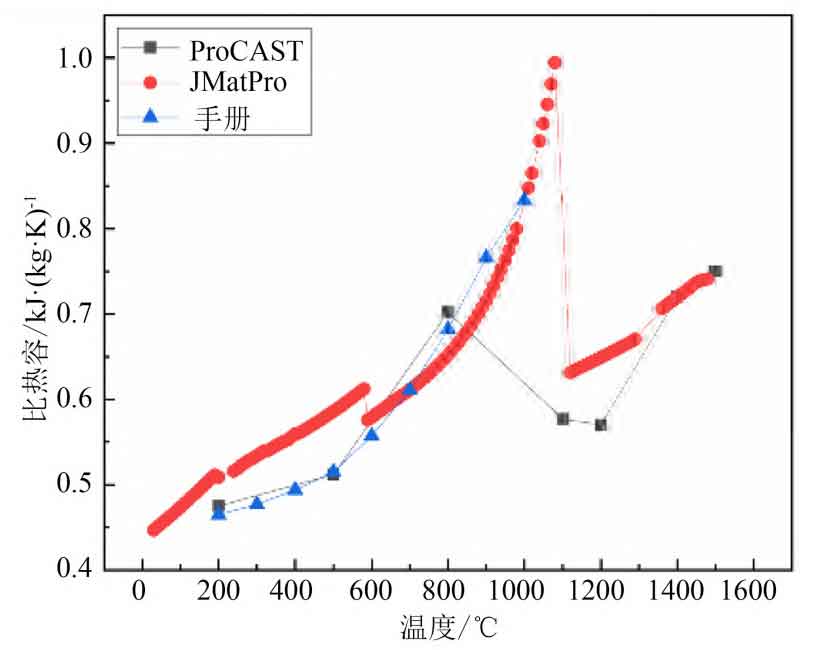

The study uses ProCAST simulation software to predict shrinkage porosity and porosity. In order to ensure the accuracy of input parameters, the thermophysical properties of K438 alloy were calculated by ProCAST and JMat ⁃ Pro, and compared with the thermophysical properties parameters in the superalloy manual. ProCAST can use three different solid diffusion models to calculate the properties of materials, namely Scheil, Lever and Back Diffusion. Scheil and Lever correspond to two different microsegregation models. Both models consider complete mixing or infinite diffusion in the melt, while Back Diffusion (back diffusion model) considers some diffusion in the solid. Generally, when the cooling rate is below 0.01 K/s, the first two solid diffusion models are selected, while the alloy with higher cooling rate uses the “anti diffusion model”. The cooling rate of the alloy in ProCAST was set at 1 ℃/s (obtained by experimental measurement), and the properties of the material were estimated by using the anti-diffusion model.

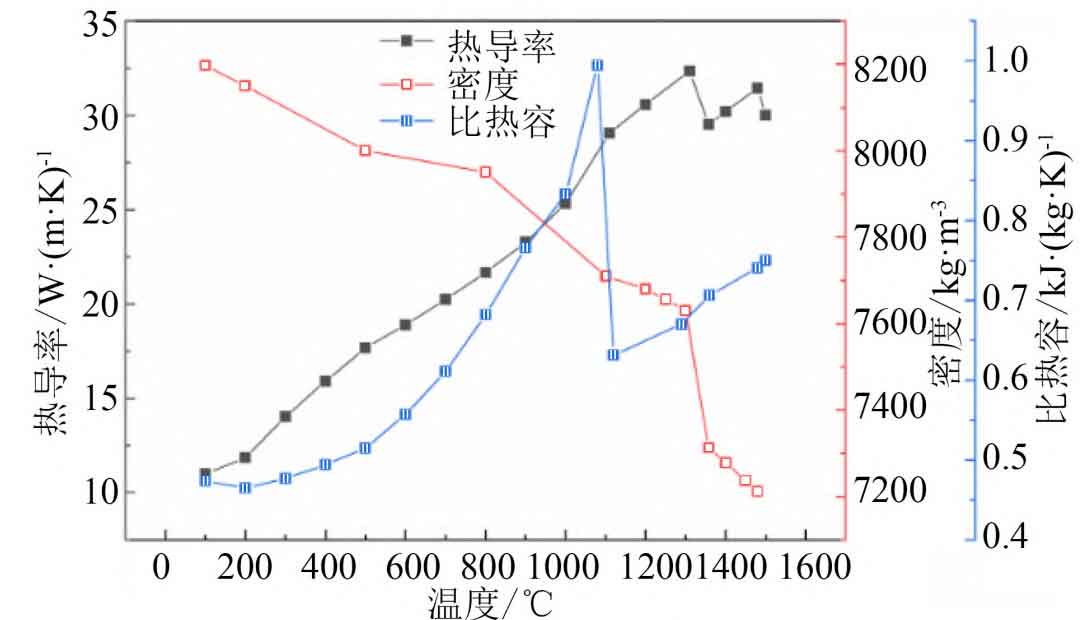

The thermophysical properties of K438 alloy during solidification at 20~1480 ℃ were simulated by JMatPro software. Draw the predicted material performance data and the K438 alloy performance data in the superalloy manual with the change of temperature into a broken line chart, and observe the change trend of various parameters with temperature and the error range between them, as shown in the figure 1. Summarize the data of various thermophysical properties parameters and fit them into a curve. Select the effective temperature range of material thermophysical properties from 100 to 480 ℃ (where 1 480 ℃ is the pouring temperature of alloy material). In order to simplify the calculation process, select the thermophysical properties parameter data on the curve of this temperature range at every 100 ℃ interval and draw the optimal thermophysical properties broken line diagram, as shown in Figure 2, and import the data into ProCAST respectively, The pouring process of K438 nickel-base superalloy was simulated.