20 ~ 60t medium frequency electric furnace is adopted for smelting, and the tapping temperature is controlled at 1580 ~ 1620 ℃. The ladle shall be baked with natural gas for more than 1h, and the red ladle (ladle wall lining temperature ≥ 800 ℃) shall be used for tapping Φ 70mm sliding nozzle. After the molten steel is discharged from the furnace, argon is blown into the ladle for refining for 5 ~ 12min. After standing, it is poured at 1560 ~ 1580 ℃. After pouring for about 2min to 150mm higher than the casting, the flow is collected and slowly poured. The molten steel rises to 2 / 3 of the riser height. It is poured from the riser. After pouring to the riser, the flow shall be appropriately reduced. Finally, the riser shall be injected according to the process requirements, Cover the riser with covering agent.

The cast steel cable clamp casting shall be cooled slowly, kept warm for a period of time, and unpacked when the temperature is lower than 300 ℃; Blowing, water drawing and impact are not allowed during sand cleaning; The riser shall be cut hot at 200 ~ 250 ℃, which shall be finished at one time, and then the sample shall be cut to rough the shape.

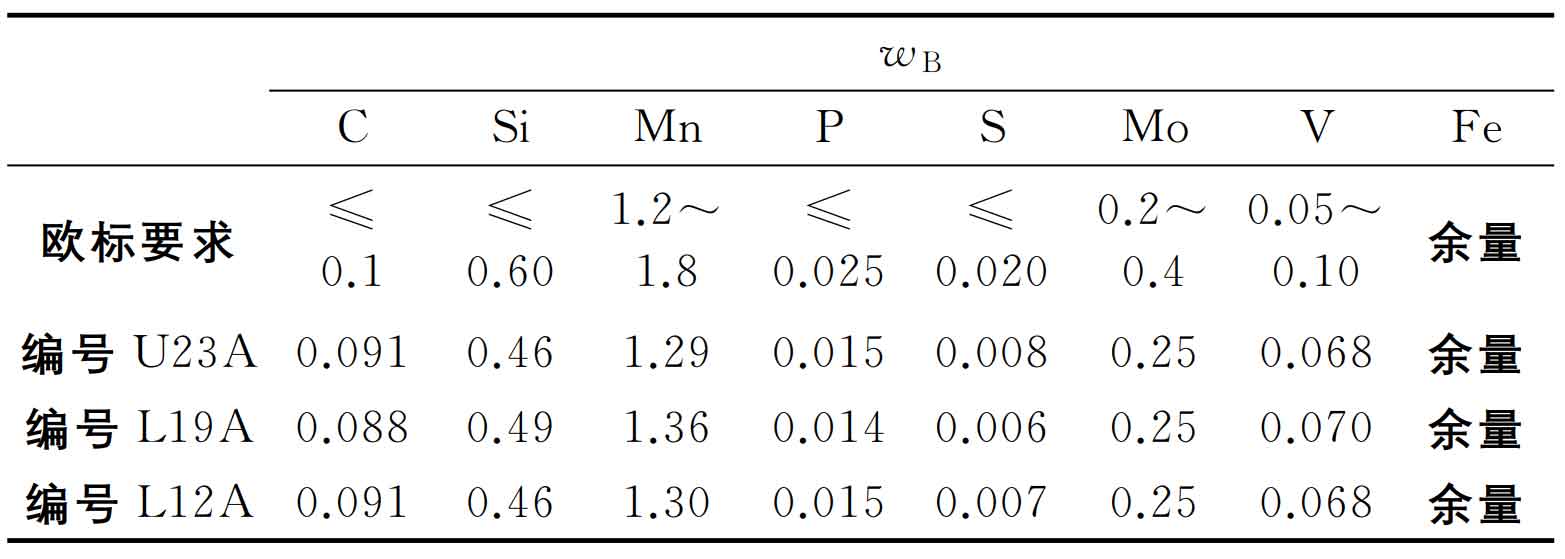

The chemical composition of small batch continuous production is shown in the table.