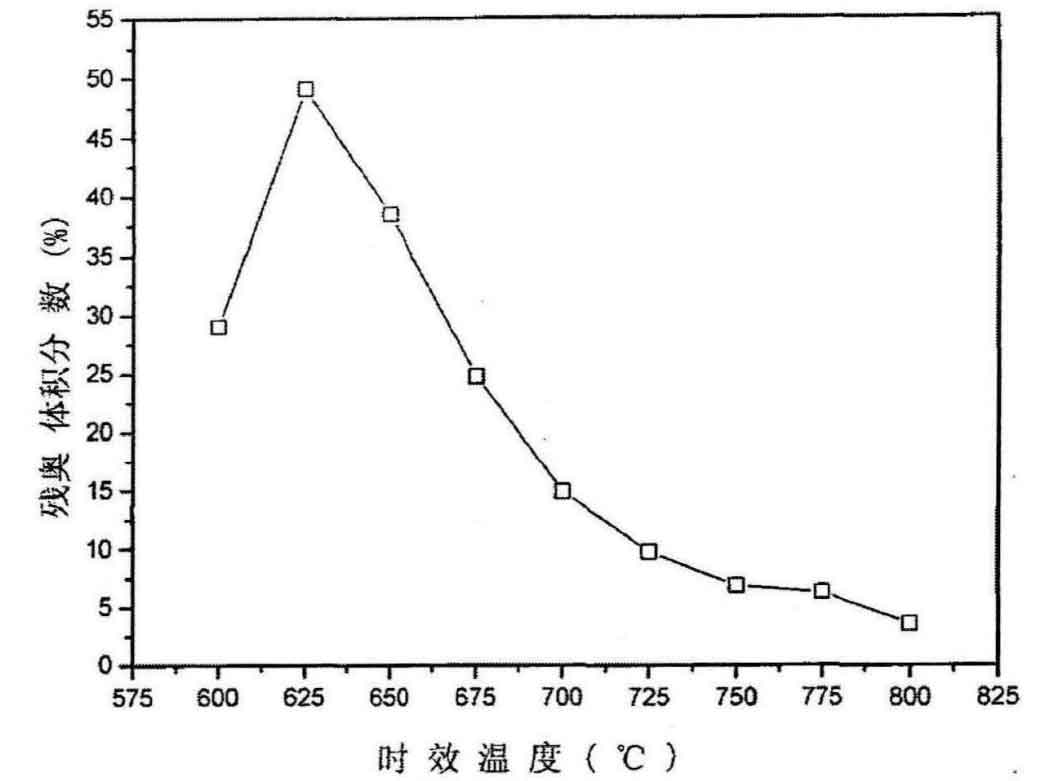

When studying 00cr13ni5co9mo5 maraging stainless steel, Luo Jing et al. Found that only a small amount of martensite was transformed into austenite phase when the aging temperature was set at 480 ° C. This aging obtained a small amount of distributed austenite while obtaining ultrafine lath martensite, which can ensure that the material has good low-temperature impact initial property and does not affect the tensile strength, However, with the increase of temperature (aging), martensite begins to transform into austenite, and the amount of austenite after aging will also increase greatly, which reduces the tensile strength of the material and the low-temperature impact toughness value. As shown in the curve in Fig. 1, when aging exceeds 625 ° C, secondary martensitic transformation may occur during reverse transformation, It is possible that at higher temperatures (625 ° C), the volume fraction of austenite begins to decrease as the temperature increases.

It is also found that the presence of the constituent element Ti also has an impact on the mechanical properties. An appropriate amount of Ti can effectively refine the austenite structure, but it can not exist too much, which will increase the brittleness temperature range and thus cause the impact value to be greatly reduced.

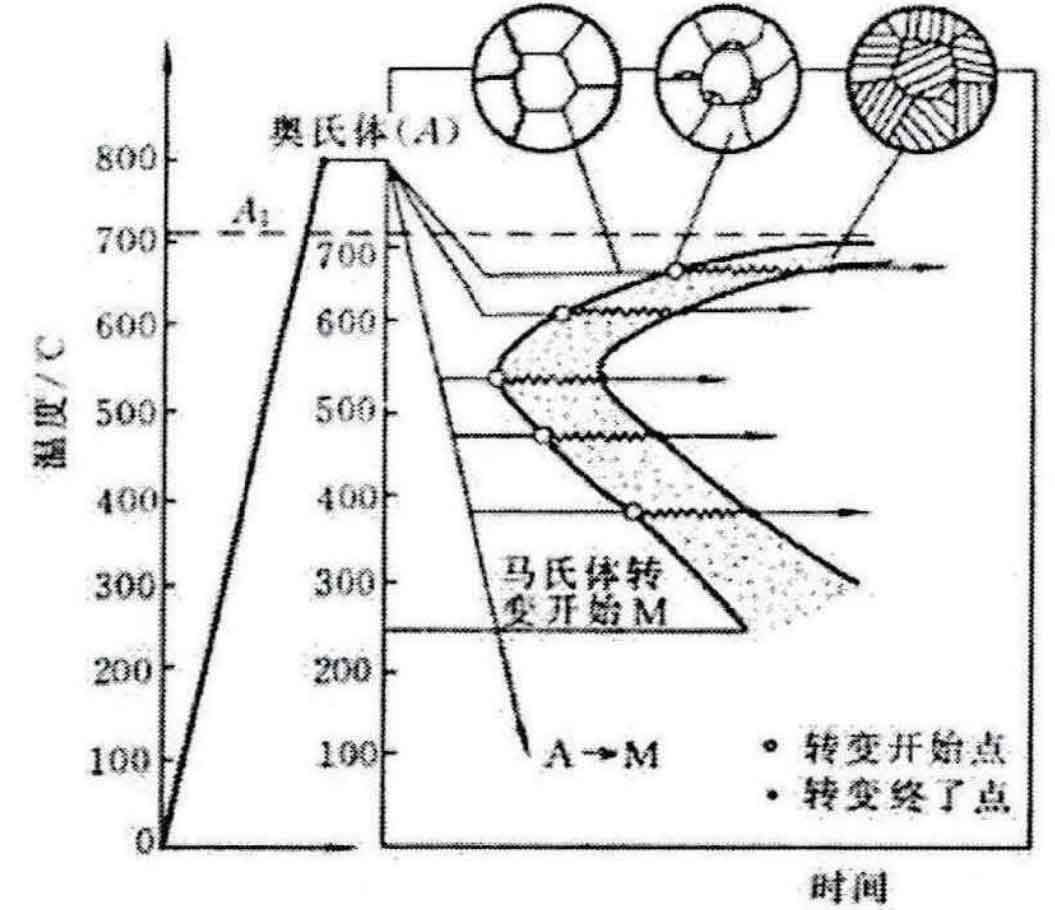

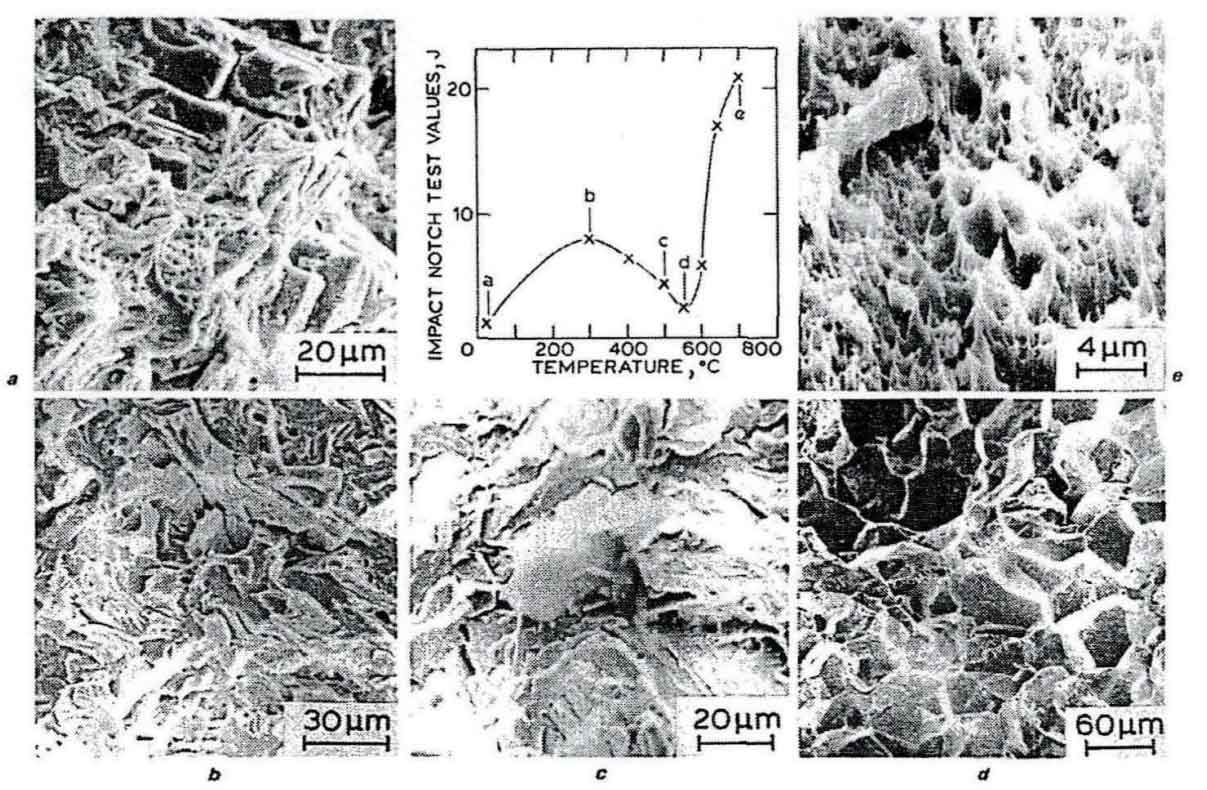

G. V. Prabhu gaunkar et al. Found that after tempering for 1 hour (100 ° C to 700 ° C), as shown in Fig. 2, there are three kinds of fracture modes in the figure. Brittle transgranular fracture (Fig. A and Fig. b). This phenomenon was observed in samples tempered to 500 ° C. The crack extends through the pre austenite grain and martensite lath. The higher the temperature (400 ° c-500 ° C), the more cleavage cracks. Brittle intergranular fracture (Fig. 3D). This is the main form of fracture observed at 550, 600 and 650 ° C.

The crack extends along the previous austenite grain boundary (Fig. 3b). Ductile failure (Figure 3e). In the samples tempered at 600 ° C or above, the fracture occurs by a mixture of intergranular and transgranular modes. However, the higher the temperature, the more important is the bremsstrahlung fracture, which is the only one found at 700 ° C. These experiments found that the embrittlement phenomenon occurred at the sample temperatures of 550 ° C and 600 ° C, their impact test values were particularly low, and the fracture diagram showed brittle intergranular damage. The samples tempered at 400 ° C and 500 ° C also have the characteristics of low initial impact strength, but the fracture diagram does not show the typical intergranular failure observed in the brittle samples. However, embrittlement can start at these temperatures, and indeed, intergranular failure occurred in some regions of these samples (Fig. 3C), but was never observed in quenched samples or samples adjusted to 350 ° C, which indicates cleavage failure (Fig. 3b).

It is also found in the literature that the alloy structure of martensitic stainless steel after adding n can become uniform, and the mechanical properties are improved. Zinner and other researchers reduced the carbon and chromium content of din1.2316 high alloy martensitic stainless steel and added nitrogen for alloying treatment to improve the solid solution level, It is also possible to prevent the precipitation of carbides such as 7m23c6 without reducing the hardness value. This can obtain uniform microstructure and eliminate the segregation of s-ferrite and carbide. A Swiss company has adjusted the content of C and n elements in 3Crl3 stainless steel. Under the condition of 0.3sc + ns0.4 content, it has a good toughness value after quenching + high temperature tempering. Perko et al. Also compared the code m333 steel with or without n addition. The hardness of the steel with 0.1wt.% addition is basically the same as that of the steel without n addition after tempering. However, the impact initial value of m333 steel with n addition reaches 50-53j. It is found that the martensitic stainless steel with n can optimize the control of the microstructure phase, thus achieving the purpose of strengthening the initial stage.