(1) Technical analysis of valve body castings: according to the requirements of user drawings, RT flaw detection shall be carried out on all cast valve bodies and all pressure bearing parts, and coloring inspection shall be carried out on all surfaces, all in accordance with level 2 standards. Pressure bearing capacity requirement 1500 × 6894.76 Pa~2500 × 6894.76 Pa。

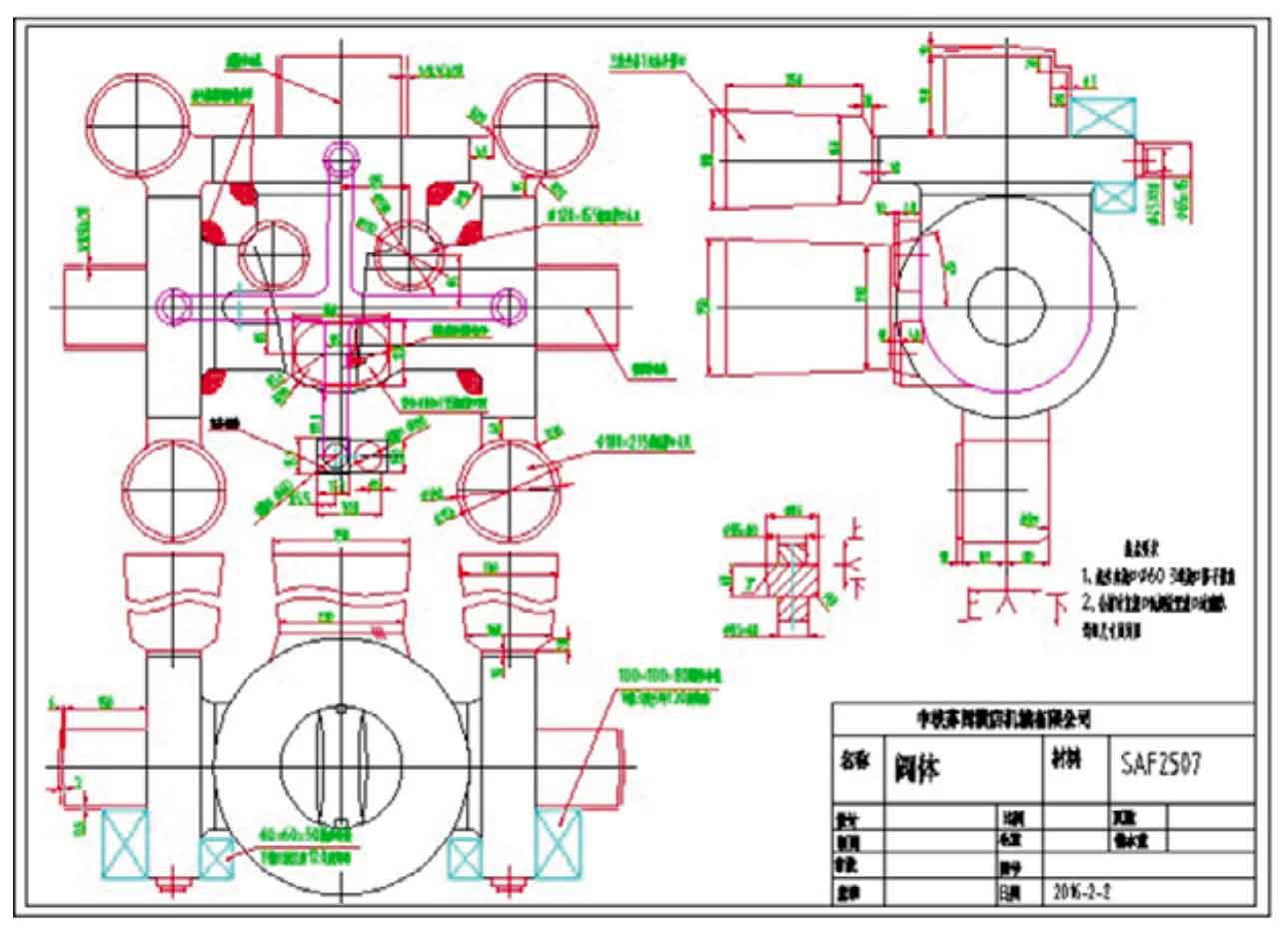

(2) Design principle: in order to solve the casting defects of high nitrogen content, easy to produce pores, shrinkage porosity and shrinkage cavity, and deal with the characteristics of poor casting performance, large volume shrinkage and large shrinkage stress, the reasonable layout of risers and increased gate flow shall be considered in the design of casting process. Multiple internal gates are adopted to improve the pouring speed and minimize the time for liquid steel to contact the atmosphere. Taking the valve body casting as an example, the casting process diagram is shown in Figure 1. Three internal gates are designed in the process drawing.

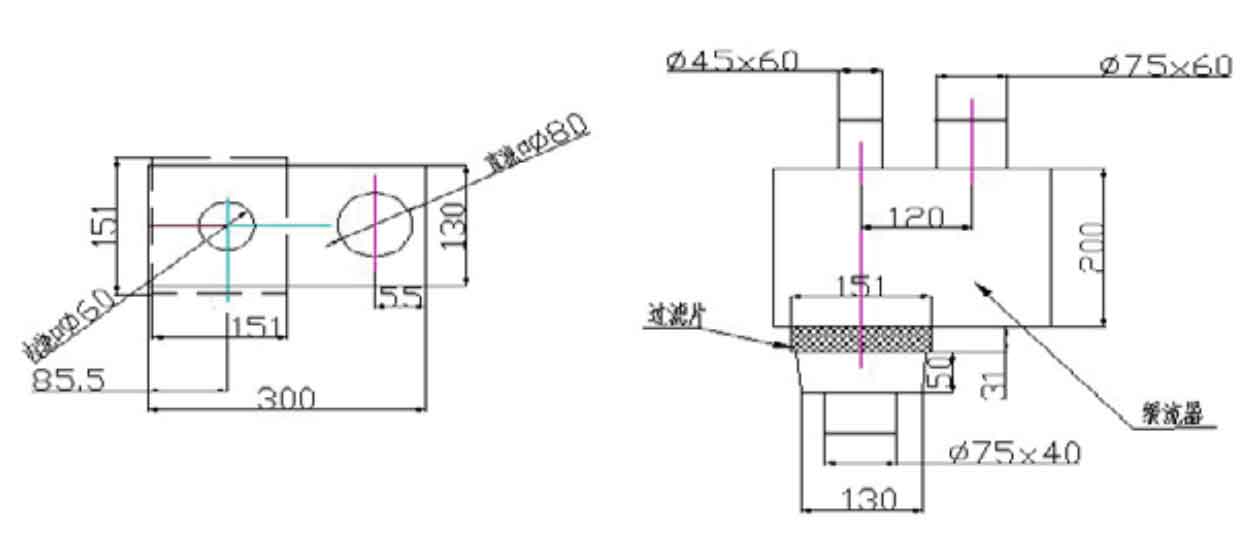

(3) Application of retarder: the bottom pouring method is adopted in the pouring system. During pouring, the liquid level of liquid steel can rise steadily to achieve sequential solidification. In addition, a retarder is placed under the straight gate, and a filter is placed at the bottom of the retarder gate.

The retarder can play two roles. The first is that the liquid steel buffer plays the role of exhaust, which can reduce the gas entrained during pouring and make the casting produce pores; The second is to install a filter at the bottom of the retarder, which can effectively filter the liquid steel and play a role in purifying the liquid steel. The buffer is commonly used in the casting production of nuclear power valves, hydrogenation valves, oil fields, chemical valves and pump parts, and has achieved good results. The design of retarder is shown in Figure 2.

(4) Verification of casting process: finally, the casting process is verified by numerical simulation calculation. Only after confirming that the casting process has no problems can it be passed and put into production. The casting process of valve body has been verified by numerical simulation.