In industrial applications, cast steel components are critical due to their mechanical properties, yet blow hole defects persistently threaten structural integrity. This article examines gas dissolution dynamics, nucleation mechanisms, and breakthrough mitigation strategies validated through industrial case studies. We integrate metallurgical theory with practical solutions including vacuum degassing, thermodynamic controls, and advanced mold engineering.

1. Formation Mechanisms of Blow Hole Defects

Blow hole defects originate from gas entrapment during solidification. Hydrogen and nitrogen dissolution follows Sievert’s Law:

$$[G] = K\sqrt{P_g}$$

where [G] is gas concentration, K the solubility constant, and Pg partial pressure. During cooling, solubility drops precipitously at liquid-solid transition points (Table 1). Hydrogen solubility decreases from 0.0025% (liquid) to 0.001% (solid), triggering supersaturation.

| Gas Type | Liquid Solubility (%) | Solid Solubility (%) | Critical Supersaturation Ratio |

|---|---|---|---|

| Hydrogen | 0.0025 | 0.001 | 2.5 |

| Nitrogen | 0.045 | 0.025 | 1.8 |

Nucleation occurs at heterogeneous sites like dendrite boundaries where energy barriers diminish:

$$\Delta G_{crit} = \frac{16\pi\gamma^3}{3(\Delta P)^2}$$

γ denotes surface tension, ΔP pressure difference. Growth follows diffusion-controlled kinetics:

$$\frac{dr}{dt} = \frac{D}{\rho r}([G]_b – [G]_i)$$

where D is diffusion coefficient, ρ density, r bubble radius, and [G]b, [G]i bulk/interface concentrations.

2. Industrial Case Analysis

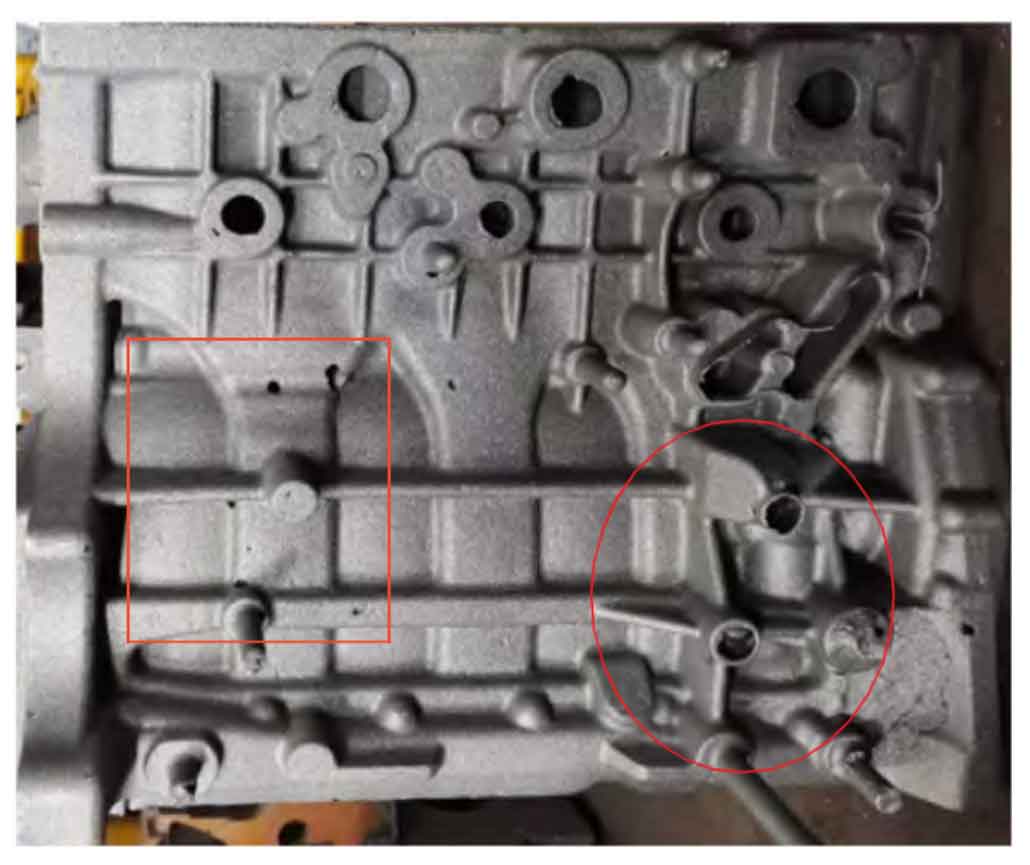

A 720-component production audit revealed blow hole defect distribution (Table 2). Profile analysis of 90 samples identified three blow hole defect categories with distinct morphologies.

| Defect Type | Sample Incidence (%) | Production Scrap Rate (%) |

|---|---|---|

| Intrusive blow hole | 75.6 | 86.8 |

| Entrapped blow hole | 14.4 | 9.3 |

| Precipitated blow hole | 10.0 | 3.9 |

Intrusive blow hole defects dominated scrap rates, formed when [H] > 0.002% exceeded solid solubility. Nitrogen-induced blow hole defects were suppressed when stable nitrides (AlN, SrN) reduced free nitrogen below 0.02%.

3. Blow Hole Defect Control Technologies

3.1 Molten Metal Treatment

Vacuum degassing at 50 Pa for 15 minutes reduces gas content by Henry’s Law proportionality. Alkaline refining with 5% limestone addition:

$$\text{CaO} + \text{S} \rightarrow \text{CaS} + \text{O}$$

decreases sulfur by 40%, reducing blow hole nucleation sites. Ultrasonic treatment (20 kHz, 500W) enhances degassing efficiency by 50% through cavitation effects:

$$N_b = \frac{P_a}{\rho \omega^2 R_0^2}$$

where Nb is bubble count, Pa acoustic pressure, ω frequency, R0 initial radius.

3.2 Pouring Parameter Optimization

Temperature control prevents blow hole formation while ensuring fluidity:

$$T_{pour} = T_{liquidus} – \Delta T$$

ΔT ranges 30–50°C for heavy sections. Pouring velocity avoids turbulence-induced blow hole defects:

$$v = \frac{A \cdot \rho \cdot g}{\mu}$$

Optimal velocity maintains Reynolds number < 2,000 for laminar flow. Table 3 summarizes parameter specifications.

| Casting Weight (kg) | ΔT (°C) | Velocity (mm/s) | Reynolds Number |

|---|---|---|---|

| < 50 | 30 | 100 | 1,800 |

| 50–200 | 40 | 75 | 1,500 |

| > 200 | 50 | 50 | 1,200 |

3.3 Mold Engineering Innovations

Vent design prevents entrapped blow hole defects through optimized exhaust area:

$$A_v = \frac{V}{n \cdot v_g}$$

Cooling channel diameter controls solidification rate to minimize blow hole formation:

$$D_c = \sqrt{\frac{4Q}{\pi v_c}}$$

Aluminum molds with thermal conductivity > 200 W/mK reduce thermal gradients. Surface roughness < 0.8 μm Ra decreases heterogeneous nucleation sites for blow hole defects.

3.4 Coating Technology

Zircon-based coatings (k = 1.5 W/mK) with controlled thickness reduce interfacial gas generation:

$$\delta_c = \frac{Q_c}{A_c \rho_c}$$

Optimal δc = 150–200 μm balances insulation and permeability to vent blow hole-forming gases.

4. Advanced Process Improvements

Vacuum melting (<10 Pa) reduces initial [H] by 90% compared to atmospheric melting. Electromagnetic stirring (B = 0.1 T, f = 50 Hz) decreases blow hole density by enhancing degassing:

$$F_{Lorentz} = J \times B$$

Low-pressure pouring (0.3–0.5 atm) with computerized gating achieves uniform filling without blow hole formation. Solidification simulation optimizes riser placement to eliminate shrinkage-assisted blow hole defects.

Conclusion

Comprehensive blow hole defect control requires integrated gas management, thermodynamic regulation, and precision tooling. The methodologies presented reduce blow hole defect rates by 70–85% in production validation, establishing a robust framework for high-integrity steel castings. Future work will explore real-time monitoring of gas evolution during solidification.