Spheroidal Graphite Iron castings are widely recognized for its excellent mechanical properties and versatility. However, its performance in aggressive environments, where corrosion and wear are significant concerns, is crucial for various applications. This article delves into the corrosion resistance and wear behavior of spheroidal Graphite Iron castings, highlighting their advantages, challenges, and recent advancements in enhancing their durability in harsh conditions.

Corrosion Resistance of Spheroidal Graphite Iron Castings

Corrosion is a primary degradation mechanism in many industrial applications. spheroidal Graphite Iron castings’s resistance to corrosion is influenced by several factors, including its composition, microstructure, and environmental conditions.

- Composition and Microstructure

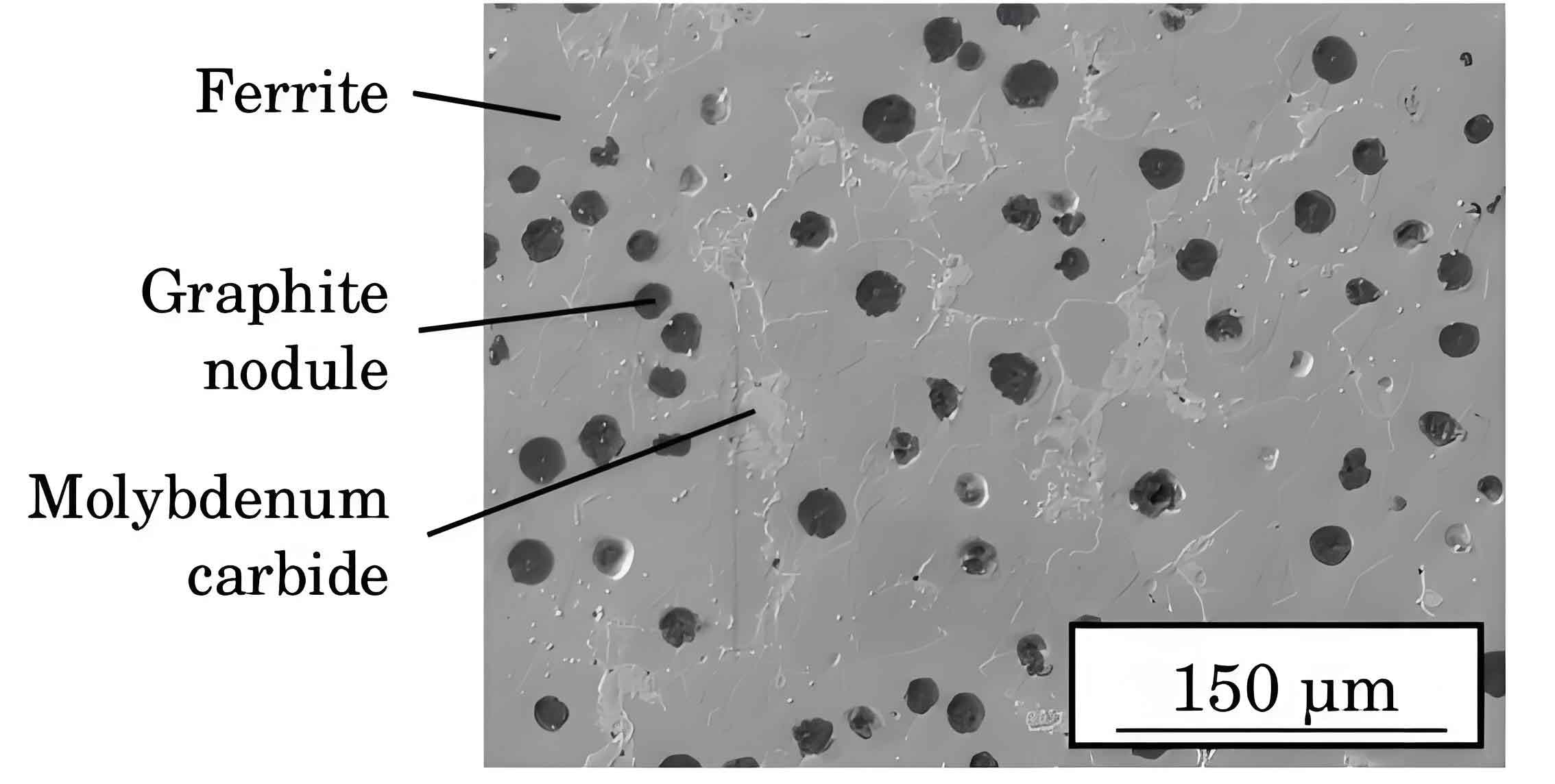

- Graphite Nodules: The presence of spheroidal graphite nodules in spheroidal Graphite Iron castings provides pathways for corrosion products to diffuse, enhancing the material’s resistance.

- Matrix Structure: The ferritic or pearlitic matrix of spheroidal Graphite Iron castings influences its corrosion behavior. A ferritic matrix generally offers better corrosion resistance compared to a pearlitic matrix.

- Environmental Factors

- Exposure to Chlorides: In environments with high chloride concentrations, such as seawater, spheroidal Graphite Iron castings susceptible to pitting corrosion. Protective coatings and alloying elements can mitigate this effect.

- Acidic Conditions: spheroidal Graphite Iron castings performs better in mildly acidic environments compared to other iron-based materials, but severe acidic conditions can still cause significant degradation.

- Protective Coatings and Treatments

- Zinc Coatings: Applying a zinc coating through galvanization provides a sacrificial layer, protecting spheroidal Graphite Iron castings substrate from corrosion.

- Epoxy Coatings: Epoxy coatings offer excellent chemical resistance, forming a barrier against corrosive agents.

- Phosphating: This surface treatment enhances corrosion resistance by forming a protective phosphate layer on spheroidal Graphite Iron castings surface.

Wear Behavior of Spheroidal Graphite Iron Castings

Wear resistance is critical for components subjected to friction and mechanical loading. spheroidal graphite iron casting’s wear behavior is determined by its hardness, microstructure, and the presence of lubricants or abrasive particles.

- Hardness and Microstructure

- Nodular Graphite: The nodular shape of graphite in spheroidal Graphite Iron castings reduces stress concentration points, enhancing wear resistance.

- Heat Treatment: Heat treatments such as austempering improve the hardness and wear resistance of spheroidal graphite iron castings by transforming its microstructure.

- Types of Wear

- Abrasive Wear: Occurs when hard particles or asperities slide across spheroidal graphite iron castings surface, causing material removal. SGI’s high hardness helps resist abrasive wear.

- Adhesive Wear: Results from the bonding and subsequent tearing of material between sliding surfaces. The smooth surface finish of spheroidal Graphite Iron castings components reduces adhesive wear.

- Erosive Wear: Caused by the impact of particles or fluid on spheroidal graphite iron castings surface. spheroidal Graphite Iron castings’s toughness and ductility help withstand erosive forces.

- Lubrication and Surface Treatments

- Lubricants: The application of lubricants reduces friction and wear in spheroidal Graphite Iron castings components, enhancing their service life.

- Surface Hardening: Techniques such as carburizing and nitriding increase surface hardness, improving wear resistance.

- Coatings: Hard coatings like chromium or ceramic provide a wear-resistant layer on spheroidal graphite iron castings components.

Innovations in Enhancing Corrosion and Wear Resistance

Recent advancements in materials science have led to several innovations aimed at improving the corrosion and wear resistance of spheroidal Graphite Iron castings.

- Alloying Elements

- Nickel and Chromium: Adding nickel and chromium improves both corrosion and wear resistance by stabilizing the microstructure and forming protective oxide layers.

- Molybdenum: Enhances the high-temperature strength and corrosion resistance of spheroidal Graphite Iron castings.

- Advanced Coatings

- Thermal Spray Coatings: Techniques such as plasma spraying and HVOF (High-Velocity Oxygen Fuel) spraying deposit wear-resistant coatings on spheroidal Graphite Iron castings surfaces.

- Nanocomposite Coatings: Incorporating nanoparticles into coatings improves their hardness and wear resistance.

- Surface Engineering

- Laser Surface Treatment: Laser treatments modify the surface microstructure, enhancing hardness and wear resistance.

- Ion Implantation: This technique introduces ions into spheroidal graphite iron castings surface, improving its wear and corrosion resistance.

Comparative Analysis of Corrosion and Wear Resistance

| Property | Spheroidal Graphite Iron with Standard Coatings | Spheroidal Graphite Iron castings with Advanced Coatings | Traditional Cast Iron | Stainless Steel |

|---|---|---|---|---|

| Corrosion Resistance | Moderate | High | Low | Very High |

| Abrasive Wear Resistance | High | Very High | Moderate | High |

| Adhesive Wear Resistance | High | Very High | Moderate | High |

| Erosive Wear Resistance | High | Very High | Moderate | High |

| Cost | Moderate | High | Low | High |

Conclusion

Spheroidal Graphite Iron castings offer significant advantages in terms of corrosion resistance and wear behavior, making them suitable for use in aggressive environments. The material’s inherent properties, combined with advanced treatments and coatings, enhance its durability and performance. As innovations continue to evolve, spheroidal graphite iron castings will likely play an increasingly vital role in applications requiring robust and reliable materials.

By understanding and leveraging these advancements, industries can ensure the longevity and efficiency of spheroidal graphite iron castings components, even in the most challenging conditions. This knowledge is essential for optimizing the use of spheroidal graphite iron castings in various sectors, from automotive to industrial machinery, contributing to overall operational excellence.